Popular searched products:

Product Description

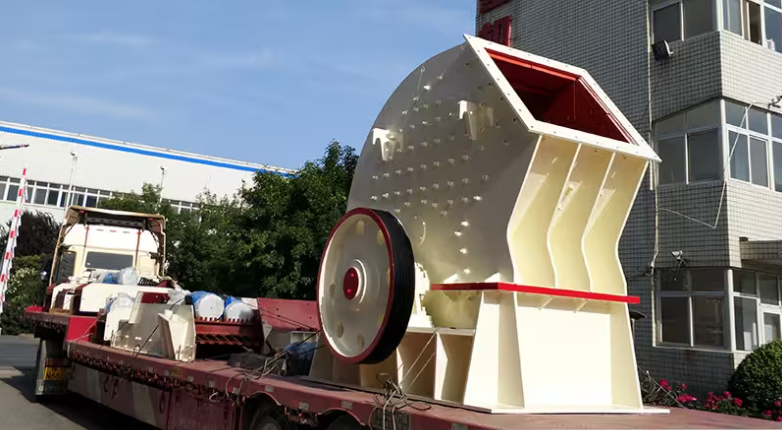

PXJ fine crusher is a new multi-functional fine crusher designed by our company based on user needs and combining the advantages of foreign crushing technology that integrates fine crushing and sand making. This fine crusher replaces part of the functions of the sand making machine and is suitable for materials with a compressive strength of no more than 150MPa and a surface moisture of no more than 10%. It is especially suitable for making abrasives, refractory materials, cement, steel sand, For fine and medium crushing of various hard and brittle materials such as quartz sand, it saves 50% energy than the traditional fine crushing sand making machine. It is an efficient, energy-saving, practical and reliable gravel sand making equipment.

Product Performance

- 1Operational advantages

The fine crusher has stable and reliable operating performance, simple structure, easy maintenance, and large production capacity. It has the same yield rate as the same traditional scale process equipment. Compared with the fine crusher, it is 30%~50% higher, and the one-time yield of particle size ≤5mm accounts for more than 85%.

- 2Crushing Advantages

When the tertiary crusher crushes, due to the special structure of the high-chromium plate hammer, coupled with the special impact lining plate, hard rock crushing, The inertial impact balancing device, simple disassembly and maintenance window, and adjustable discharge particle size simplify the crushing process.

- 3Structural Advantages

The structure of the fine crusher is more reasonable. It adopts a special dust-proof sealing structure internally, and the electrical system also adopts special electrical The control system, as well as some electronic intelligent anti-theft systems, are beneficial to extending the replacement cycle of lubricating oil and the service life of parts, and can also safely control oil temperature, oil pressure, and oil flow to take measures in emergency situations.

Working Principle

The fine crusher is a continuous operation equipment. The materials enter the cavity sequentially from the feed inlet and fall on the high-speed rotating movable hammer head. Through the action between the hammer and the impact plate, the materials are initially crushed. After being repeatedly hammered and counterattacked at high frequency for many times, the material forms an accumulation on the middle partition, slides down, falls on the throwing plate of the lower rotor rotating at high speed, and is thrown to the counterattack plate at high speed, where it collides, falls and passes through. The mobile blow hammer is forced to carry out counterattack, crushing and grinding. Therefore, the material undergoes multiple compound crushing, scouring and grinding during the falling process under its own weight to achieve ultra-fine effect and is discharged through the discharge port.

Technical Parameters

| Model | Inlet size (mm) | Inlet size (mm) | Discharge particle size (mm) | Discharge seam adjustment width (mm) | Processing capacity (t/h) | Power (kw) |

| PXJ800×400 | ≤120 | 400×185 | ≤5 | 5-20 | 20-45 | 37-45 |

| PXJ800×600 | ≤180 | 500×250 | ≤5 | 5-20 | 35-55 | 45-55 |

| PXJ800×800 | ≤180 | 550×330 | ≤5 | 5-20 | 35-65 | 45-55 |

| PXJ1010×1010 | ≤180 | 1000×350 | ≤5 | 5-20 | 45-75 | 55-75 |

| PXJ1200×1000 | ≤180 | 1200×400 | ≤5 | 5-20 | 70-110 | 90-110 |

| PXJ1200×1200 | ≤180 | 1200×450 | ≤5 | 5-20 | 90-120 | 110-132 |

| PXJ1400×1400 | ≤190 | 1500×500 | ≤5 | 5-20 | 100-150 | 160 |

| PXJ1600×1600 | ≤190 | 1600×550 | ≤5 | 5-20 | 170-250 | 250 |

| PXJ1800×1800 | ≤190 | 1800×800 | ≤5 | 5-20 | 250-310 | 315 |