Popular searched products:

Product Description

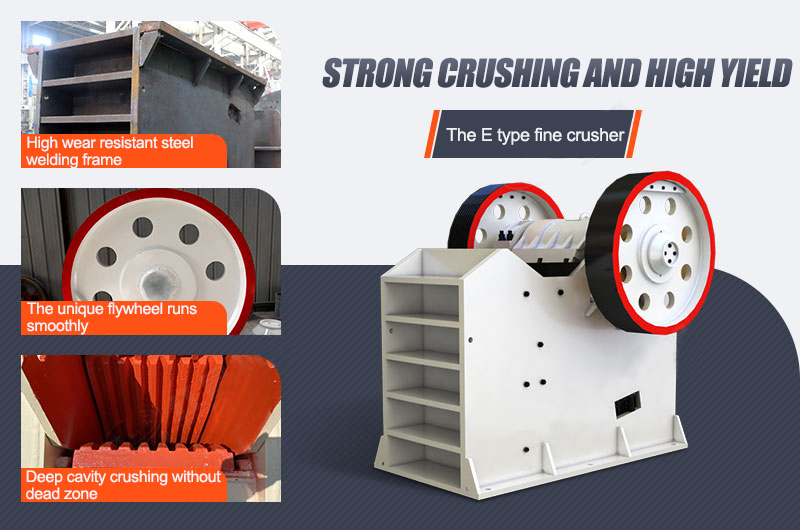

PE jaw crusher is one of the mainstream crushing equipment with the largest sales volume and high production efficiency in the mining equipment industry. It is widely used in metallurgy, mining, chemical industry, cement, construction, refractory materials, ceramics and other industrial sectors to complete various crushing operations. Coarse crushing of medium-hard ores and rocks. It is often combined with cone crusher, impact crusher, sand making machine, etc. to form a complete sand and gravel production line.

Product Performance

- 1Good stability and high reliability

PE jaw crusher movable jaw assembly is made of high-quality steel castings, and the heavy-duty eccentric shaft is also used The forging billet is processed, all of which make the jaw crusher have extraordinary stability. Compared with other crushers of the same specifications, we use larger and more durable eccentric shaft bearings to give it a higher load-bearing capacity and ensure its reliability.

- 2Advanced technology and long service life

Adopt advanced manufacturing technology and use advanced digital component processing equipment to ensure the precision of machine components; select high-end Made of advanced materials, it greatly enhances its pressure resistance and wear resistance, and greatly extends the service life of the machine.

- 3Simple structure and easy maintenance

After continuous improvement and optimization, while ensuring the improvement of machine performance, the machine structure has also been simplified. The entire machine is easier to operate, maintenance is more convenient, and downtime for maintenance is greatly shortened.

- 4Large production capacity and good finished product shape

PE jaw crusher adopts advanced crushing principles, which significantly increases the proportion of cubes in the product. Shape stones are reduced in particle size and more uniform.

Working Principle

The working mode of this series of crushers is drive extrusion type. Its working principle is: the motor drives the belt and pulley, and the movable jaw moves up and down through the eccentric shaft. When the movable jaw rises, the angle between the toggle plate and the movable jaw becomes larger. , thus pushing the movable jaw plate closer to the fixed jaw plate, and at the same time, the material is crushed or chopped to achieve the purpose of crushing; when the movable jaw moves downward, the angle between the toggle plate and the movable jaw becomes smaller, and the movable jaw plate moves on the pull rod, Under the action of the spring, the jaw plate leaves the fixed jaw plate, and the crushed material is discharged from the lower opening of the crushing cavity. As the motor continuously rotates, the movable jaw of the crusher makes periodic movements to crush and discharge materials, thus realizing mass production.

Technical Parameters

| Model | Feeding size (mm) | Output size (mm) | Processing capacity (t/h) | Motor power (kw) | Dimensions (mm) |

| PE150×250 | ≤130 | 15-45 | 1-4 | 5.5 | 896×745×935 |

| PE250×300 | ≤150 | 15-55 | 3-6 | 7.5 | 1050×987×1000 |

| PE250×400 | ≤210 | 25-60 | 5-20 | 15 | 1215×1520×1030 |

| PE400×600 | ≤350 | 40-90 | 15-60 | 30 | 1650×1588×1050 |

| PE500×750 | ≤425 | 50-100 | 40-110 | 45 | 1956×1918×1920 |

| PE600×900 | ≤500 | 60-125 | 90-180 | 55 | 2250×2733×2280 |

| PE800×900 | ≤600 | 80-140 | 100-220 | 75 | 2450×2950×2490 |

| PE750×1060 | ≤630 | 60-150 | 110-380 | 110 | 2531×2455×2783 |

| PE900×1060 | ≤700 | 100-160 | 230-390 | 110 | 2900×2657×2950 |

| PE900×1200 | ≤750 | 110-165 | 220-450 | 132 | 3100×2760×3260 |

| PE1000X1200 | ≤900 | 110-185 | 315-500 | 132 | 3200×2760×3260 |

| PE1200×1500 | ≤950 | 115-195 | 550-1000 | 220 | 3710×3446×4075 |

| PE1500×1800 | ≤1200 | 135-225 | 600-1200 | 280 | 5100×4700×4300 |

| PEX150×750 | ≤120 | 10-40 | 8-25 | 15 | 1310×1118×1145 |

| PEX250×750 | ≤210 | 15-50 | 15-35 | 22 | 1400×1751×1515 |

| PEX350×750 | ≤300 | 15-50 | 18-40 | 30 | 1485×1680×1648 |

| PEX250×1000 | ≤210 | 15-60 | 15-60 | 30 | 1550×1964×1380 |

| PEX250×1200 | ≤210 | 15-60 | 20-60 | 37 | 1530×1946×1380 |

| PEX300×1300 | ≤250 | 25-60 | 16-105 | 55-75 | 2000×2320×1730 |