Popular searched products:

Product Description

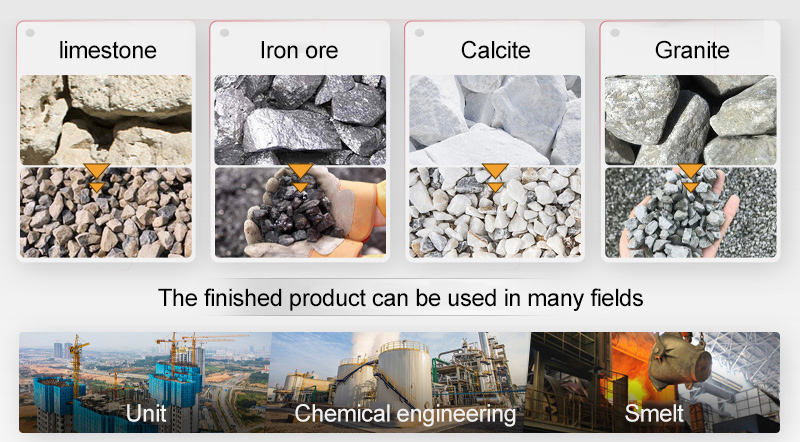

The compound cone crusher is a new crushing product optimized and designed by our company based on domestic and foreign fine crushing technology. It has excellent equipment performance and technology, high cost performance, large crushing ratio, high efficiency, high processing capacity, low operating cost, and easy adjustment. Economical use and other features.

In medium and large size compound cone crushers, a hydraulic cavity clearing system is used to reduce downtime, and there are many crushing cavity types for each size. Users can choose different cavity types according to different needs to better Adapt to user needs. A single machine can be assembled on a motorized carrier to form a mobile compound cone crusher, which operates in flow crushing mode.

Product Performance

- 1Good lubrication and reliable operation

The compound cone crusher adopts grease sealing to avoid the shortcomings of easy blockage of water supply and drainage systems and easy mixing of water and oil. The defect is that the spring safety system is an overload protection device that allows foreign objects and iron blocks to pass through the crushing chamber without harming the crusher.

- 2Strong processing capacity

The perfect combination of high-performance crushing cavity and high crushing frequency greatly improves the processing capacity, and due to the adoption of the lamination crushing principle , so the crushed products are mostly cubic structures, which greatly reduces needle and flake materials.

- 3Reliable performance and extremely low failure rate

Through the optimized design of the compound cone crusher, the equipment performance is more reliable, easy to operate, and adopts full hydraulic It is easy to operate and use, easy to realize automation, its reliability and lifespan are greatly improved, and the equipment failure rate is reduced by more than 90%.

- 4Easy to operate, long service life

The compound cone crusher has a simple structure, easy to operate and maintain, the discharge opening is convenient and quick to adjust, and maintenance saves time and effort. Liners in particular are easy and quick to replace, reducing downtime.

Working Principle

When the compound cone crusher is working, the motor drives the transmission shaft of the machine through a pulley or coupling. The cone part of the machine makes a swing motion around a fixed point under the force of the eccentric sleeve. As a result, the crushing wall of the crushing cone sometimes approaches and sometimes leaves the surface of the rolling mortar wall fixed on the adjusting sleeve, so that the ore is continuously impacted, squeezed and bent in the crushing cavity to achieve the crushing of the ore. The electric motor drives the eccentric sleeve to rotate through the bevel gear, causing the crushing cone to perform a pendulum motion. The crushing cone sometimes approaches and sometimes leaves the fixed cone to complete crushing and discharge.

Technical Parameters

| Model | Diameter of moving cone (mm) |

Feeding port size (mm) | Discharge opening size (mm) | Spindle speed (r/min) | Motor power (kw) | |

| Feed size(mm) | Opening size(mm) | |||||

| CS75 | 910 | 83 159 |

102 175 |

9-22 13-38 |

580 | 75 |

| CS110 | 1200 | 127 | 131 | 9-31 | 485 | 110 |

| 156 | 156 | 13-38 | ||||

| 178 | 191 | 19-51 | ||||

| CS160 | 1295 | 109 | 137 | 13-31 | 485 | 160 |

| 188 | 210 | 16-38 | ||||

| 216 | 241 | 19-51 | ||||

| CS220 | 1395 | 155 | 173 | 25-65 | 485 | 220 |

| 188 | 198 | 22-50 | ||||

| 230 | 245 | 19-45 | ||||

| CS250 | 1650 | 188 | 209 | 16-38 | 485 | 250 |

| 213 | 241 | 22-51 | ||||

| 241 | 268 | 25-64 | ||||

| CS315 | 2134 | 253 | 278 | 19-38 | 435 | 315 |

| 303 | 334 | 25-51 | ||||

| 334 | 369 | 31-64 | ||||