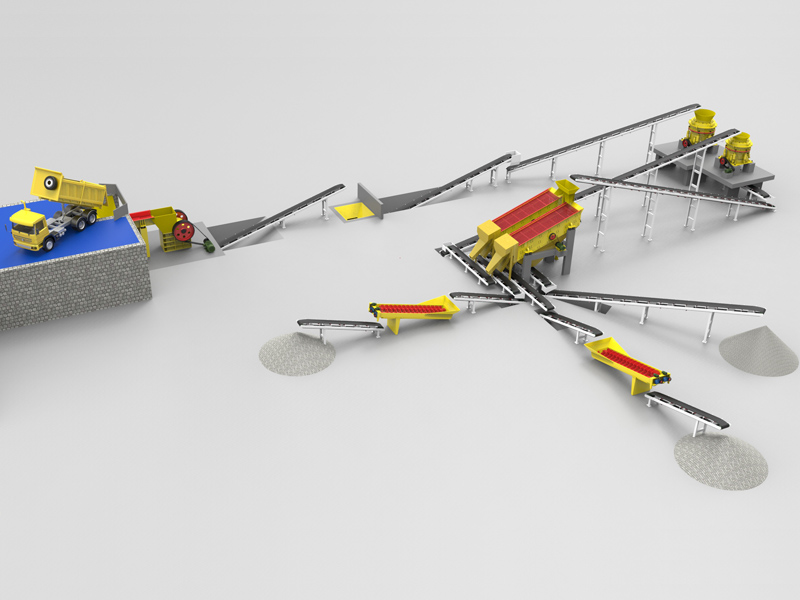

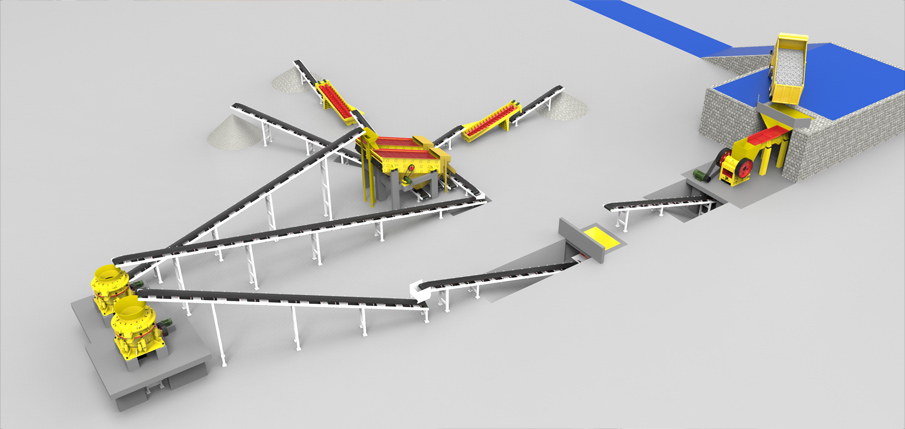

400 tons of double cone crushing production line

Production Capacity:400t/h

Processing materials:Limestone, granite, basalt, river pebbles, slag and other materials

Power Consumption:

Production Capacity:400t/h

Processing materials:Limestone, granite, basalt, river pebbles, slag and other materials

Power Consumption:

Global Heavy industry quality is good

The jaw crusher and cone crusher line is a line for processing ores, rocks and other hard materials. The production line is mainly composed of jaw crusher and cone crusher, through the cooperation of the two crushers, to achieve the gradual crushing and processing of raw materials.

Jaw crusher: As the first crushing equipment in the production line, the jaw crusher is mainly responsible for the preliminary crushing of large pieces of raw materials. The working principle is to break the raw material into smaller chunks by clamping and squeezing between the two jaw plates. The crushed material is discharged through the bottom and enters the next crushing process.

Cone crusher: Cone crusher is the second crushing equipment of the production line, which is responsible for further crushing the material treated by the jaw crusher into finer particles. The working principle of the cone crusher is to break the material through the extrusion, bending and shearing between the rotating cone and the fixed cone. The crushed material is screened by the screening equipment to meet the required particle size, and the final product is obtained.

High efficiency: Jaw crusher and cone crusher are efficient crushing equipment, can quickly process a large number of raw materials, improve production efficiency.

Good crushing effect: Through the cooperation of two crushers, the gradual crushing and processing of raw materials can be achieved, and the finished products with uniform particle size and stable quality can be obtained.

Wide range of application: The production line is suitable for processing ores, rocks and other hard materials of various hardness, with strong versatility.

High degree of automation: The production line can achieve automatic control, reduce the degree of manual intervention, and improve production safety and stability.

The mined limestone is first sent to the vibration feeder from the silo, the vibration feeder mainly sends the material evenly to the jaw crusher for initial breaking, the limestone material after initial breaking is transported to the cone crusher for crushing under the action of the belt conveyor, the broken material is screened by the circular vibrating screen, and the material greater than 20mm is sent to the cone crusher for continued crushing. The qualified material is sent to the spiral sand washing machine by conveyor. The material out of the sand washing machine is delivered to the finished product pile by belt conveyor.

Since the production, the stone production line has been widely praised. The customer said that the line not only improves production efficiency, but also significantly improves product quality and meets market demand.