50 tons per hour limestone grinding production line

Production Capacity:20-50t/h

Processing materials:limestone

Power Consumption:N

Production Capacity:20-50t/h

Processing materials:limestone

Power Consumption:N

Global Heavy industry quality is good

Limestone is a kind of mineral. It is widely distributed in my country and has abundant reserves. It is a valuable resource with a wide range of uses. After being processed through processes such as crushing, grinding, and screening, it can be widely used in building materials, producing Portland cement, and producing coating-grade heavy calcium carbonate products for papermaking. It is an important raw material for many industries. This production line is a relatively common limestone grinding processing solution, and the finished products and benefits are also very good.

This powder processing company has limited project space. At the same time, it pays special attention to whether the equipment is energy-saving, environmentally friendly, and in compliance with national standards. After on-site survey and on-site inspection, a solution for the European version of the trapezoidal grinding powder production line was given to solve the project difficulties.

Material: Limestone (0-12mm) (CaO > 81.6%, humidity < 0.1% H2O)

Discharge size: 74μm (200 mesh) D90

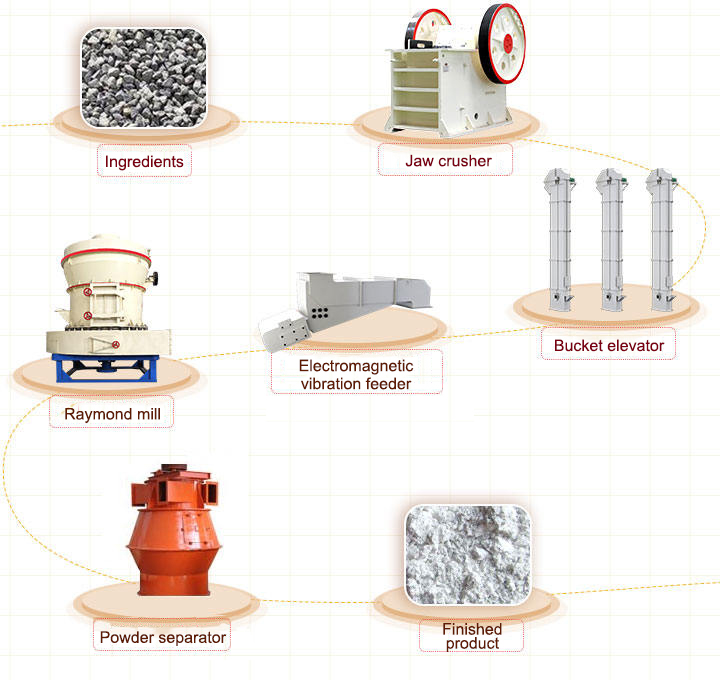

Equipment: jaw crusher, fighter elevator, vibrating feeder, European mill, powder separator

Usage: The finished product is used for desulfurization in power plants

01. Reasonable layout to solve site planning needs

Conduct a detailed survey of the site, fully combine the compact layout characteristics of the MTW grinding mill, and carry out reasonable planning and layout in the reserved space to successfully solve the site planning needs.

02. Deliver on time to help quickly put into production and make profits

In order to achieve the desired production line construction speed, detailed plans for production, shipment preparation, basic production, and engineer dispatch for installation and debugging are formulated to facilitate rapid production and rapid profitability.

03. Environmentally friendly and intelligent, ensuring automation & dust-free

Pulse dust removal equipment is installed in the loading, grinding, finished product transportation and storage links to ensure that the production site is clean and environmentally friendly and free of dust pollution. It is equipped with PLC intelligent control cabinet and remote central control system to save labor costs and make the operation simple and fast.

04. Improve equipment quality to reduce costs and increase efficiency

The MTW European version of the grinding mill used in this project uses wear-resistant alloy grinding rollers and rings, and its service life is 1.7-2.5 times that of traditional wear-resistant parts; the combined design can more effectively save the cost of wear-resistant parts and achieve Reduce costs and increase efficiency.

1. After the limestone is crushed by the jaw crusher, it is sent to the storage bin by the elevator, and then evenly sent to the middle of the turntable of the Raymond mill through the electromagnetic vibrating feeder. The material is dispersed under the action of centrifugal force. The material will fall into the ring and be crushed by the ring roller. After being crushed in the first layer, the material will fall into the second and third layers. The suction action of the high-pressure centrifugal fan will blow the external air. The coarse powder is sucked into the machine and brought into the powder separator after being crushed in the third layer.

2. The rotating turbine in the powder concentrator causes the coarse-grained materials to fall back for regrinding, while the fine powder enters the cyclone powder collector with the airflow and is discharged from the discharge valve at the bottom to become the finished product. The air flow is purified by the pulse dust collector and then discharged through the fan and muffler. The production line is equipped with high-performance grinding equipment, which is simple to operate and effective in energy saving. The application of pulse dust collector greatly reduces dust pollution during the production process and protects the on-site production environment.

Global Heavy Industries' grinding mills rarely break down, and the wearing parts are very durable. The entire production line consumes little energy but has high output, and is very environmentally friendly and energy-saving. From the initial field trip to the manufacturer to purchase the machine, to the delivery and installation, including the subsequent after-sales service, the staff of Global Heavy Industries were very enthusiastic and responsive. More importantly, the equipment has good production capacity and reliable quality.