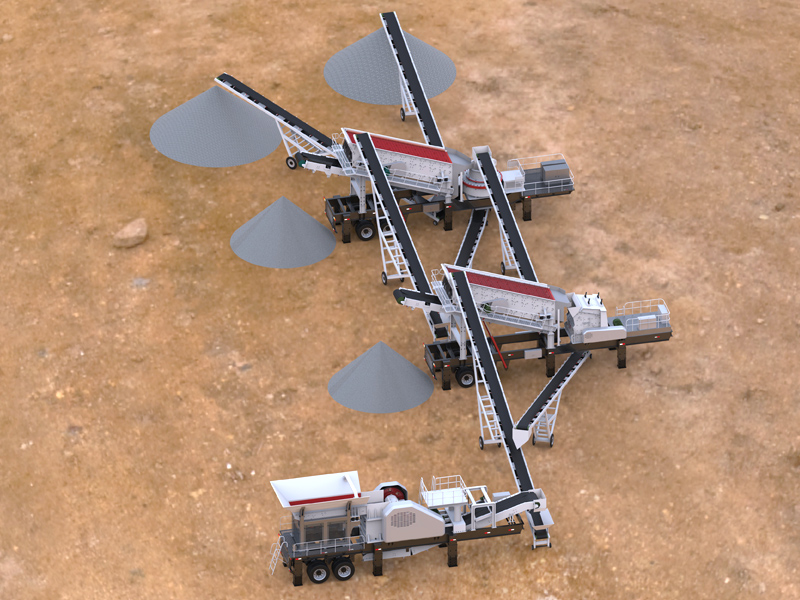

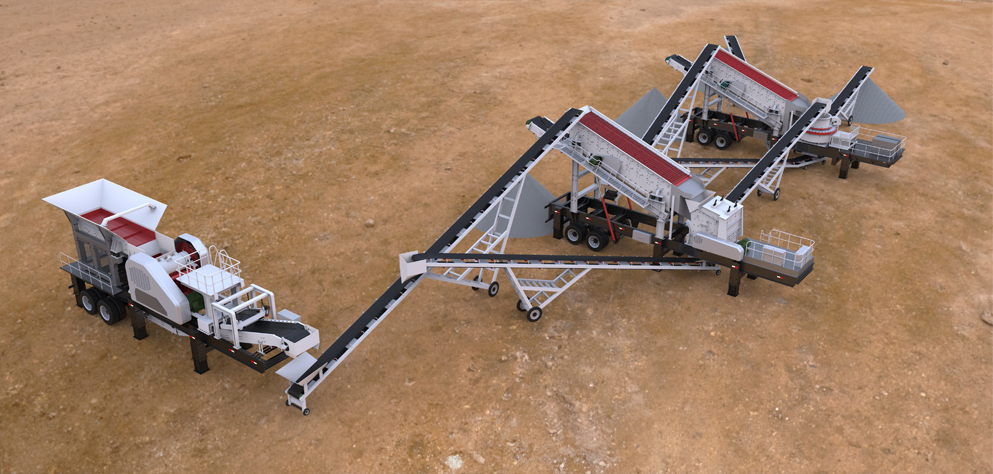

Construction waste crushing sand production line

Production Capacity:500t/h

Processing materials:Construction waste, waste concrete, rock, limestone, etc

Power Consumption:暂无数据

Production Capacity:500t/h

Processing materials:Construction waste, waste concrete, rock, limestone, etc

Power Consumption:暂无数据

Global Heavy industry quality is good

In the face of a large number of construction waste resources, this production line takes the lead in establishing a special construction waste disposal site, implementing standardized operations of unified recycling and unified treatment, and investing in the nearby introduction of a counter-attack mobile crushing station to produce recycled aggregate, and establishing a brick factory nearby, using construction soil head to make bricks. The wall bricks produced are not only cheap, but also can be used as a complete substitute for clay bricks.

A, free to transfer, not restricted by resources

The mobile crushing station can move freely, especially the tire crushing station, which can be transported long distance under the traction of the front, and can respond freely to resource depletion or policy risks, and the fault tolerance rate is higher.

Two, fast production, immediate results

The mobile crushing station is generally equipped with feeding equipment, crushing equipment and screening equipment, as well as belt conveying equipment, which has been assembled in the factory, the crawler mobile station does not need to do the foundation, and the wheeled mobile station only needs to fix four legs after arriving at the site (the embedded parts and anchor bolts need to be done in advance, which can be completed during the production of the mobile station in the factory). Compared with the fixed crushing equipment, the operation period of the mobile crushing station is shorter, and it can be quickly put into production and obtain returns.

Saving raw materials and transportation costs

The mobile crushing station can be broken nearby and processed on the spot, which can reduce the transportation cost of raw materials. Although the transportation cost of raw materials per ton is limited, it is a considerable number for a material yard with an annual processing capacity of one million tons. In addition, the mobile crushing station enhances the user's ability to choose resources, and the user can choose low-cost raw materials, which is nothing more than the crushing station, which is much lower than the transportation cost of raw materials.

Four, can fight alone, can also be combined

The mobile crushing station is self-contained and can generally complete independent crushing tasks, such as the mobile jaw crusher station can complete the coarse crushing task, which can meet the needs of some construction sites. When encountering complex crushing tasks, mobile crushing stations can be flexibly combined to overcome them together. You can fight alone or in combination.

In the crushing process of construction waste recycling fine aggregate, due to the physical characteristics of the material itself, two-stage crushing is usually used, and the particle size of the crushed product is 0-10mm, accounting for about 25%. In order to increase the yield of fine aggregate, the use of two-stage crushing for three-stage crushing, so that most of the crushed products reach 0-10 below, is a very effective means.

Construction waste in the operation process of concrete, waste bricks, stones, etc. into the jaw crusher for simple coarse crushing, and then into the construction waste crusher for fine crushing, and then into the vibrating screen for screening. Qualified stone through the belt conveyor into the dry magnetic separator for iron removal treatment, transported by the belt to the sand shaping machine for shaping sand, unqualified stone again into the construction waste crusher for crushing, thus forming a closed cycle to ensure the quality specifications of stone.

This production line operation in the past two years, the effect makes us very satisfied, the price of mobile stone crusher is also affordable, the overall investment cost is very provincial, and after-sales service makes us feel very intimate, the equipment will soon be shipped, responsible for operation training, regular maintenance and other services in the later period, to maintain high equipment efficiency and stable operation, so we want to continue to cooperate.