How to determine the appropriate filtration air speed for bag filter dust collector

2025/03/20 09:46:18Popular searched products:

Professional mining machinery and equipment supplier, can provide you with overall solutions for mining machinery and equipment

Collect mining machinery knowledge and grasp the trends of mining machinery

How to determine the appropriate filtration air speed for bag filter dust collector

2025/03/20 09:46:18

Early rotary kilns were mainly used in the cement industry, but today their applications have expanded to multiple fields such as building materials, metallurgy, chemical engineering, and environmental protection. The rotary kiln series products produced by Henan Global Heavy Industry have been widely used in multiple industries, which not only reflects the maturity and diversity of rotary kiln technology, but also highlights its importance in modern industry.

2025/03/20 09:45:00

What are the reasons for the displacement and vibration of the cement grinding gear

2025/03/20 09:43:14

The maintenance and upkeep of cement mills is a crucial daily task that must be closely integrated with operations and repairs, and should be regularly inspected by specialized personnel.

2025/03/20 09:36:33

Let's talk about choosing the right grinding process. Grinding is the process of using machine power to grind cement. This process is actually a physical activation process, which means that the mill provides energy to the cement particles by using a liner plate, and the overall reaction area is greatly increased, ultimately generating a hydrated gel micron sized powder with high coagulation ability.

2025/03/20 09:35:12

The operating efficiency of the cement mill is closely related to the cost of the entire production line, and the steel consumption of the grinding body and lining plate is one of the important factors affecting the efficiency of the cement mill. When the lining plate and grinding body are severely worn, the output capacity of the mill will be significantly reduced, resulting in an increase in unit power consumption for cement production. Therefore, it is crucial for cement production to effectively reduce the steel consumption of the abrasive body and extend the service life of the liner.

2025/03/17 10:09:27

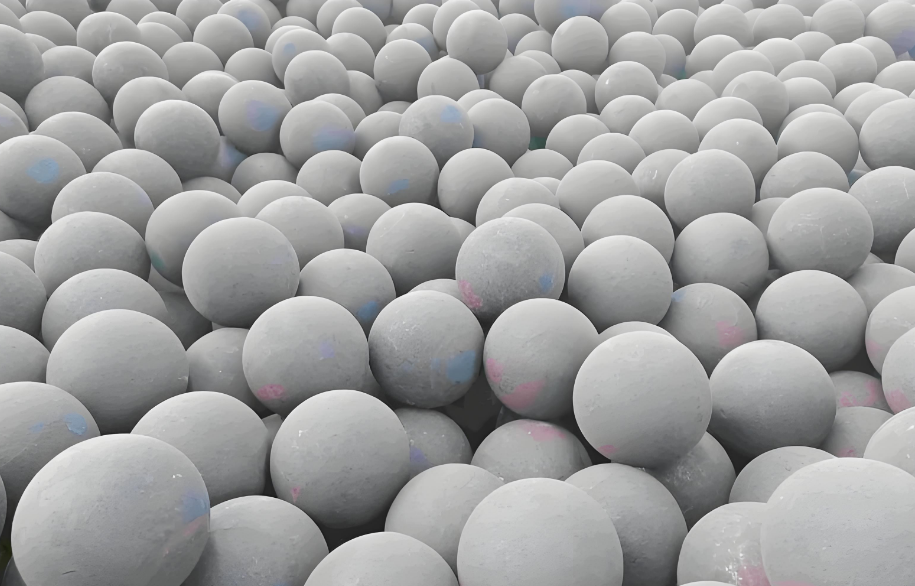

Ball mill is a kind of equipment widely used in material research and industrial production. Its principle involves the grinding and mixing of particles. In this article, we will discuss in detail the working principle of the ball mill and its key role in powder metallurgy and new material synthesis.

2025/03/17 10:04:14

How to prevent and solve the phenomenon of egg formation and agglomeration in rotary kiln?

2025/03/17 09:59:08

The main function of the steel balls in the ball mill is to impact and crush the materials, and also to have a certain grinding effect. Therefore, the gradation design of the steel balls is designed to meet these two requirements. The quality of the crushing effect directly affects the grinding efficiency and ultimately determines the output of the ball mill. Whether the expected crushing effect can be achieved depends on whether the gradation of the steel balls is reasonable, which mainly involves the size of the steel balls, the number of ball diameters, and the proportion of steel balls of different specifications.

2025/03/06 10:48:34

The so-called two-stage ball distribution method is to use two different sizes of steel balls with a large difference in diameter for grading. The theoretical basis is that the gaps between the large balls are filled with small balls to fully increase the packing density of the steel balls.

2025/03/06 10:46:58