Popular searched products:

Product Description

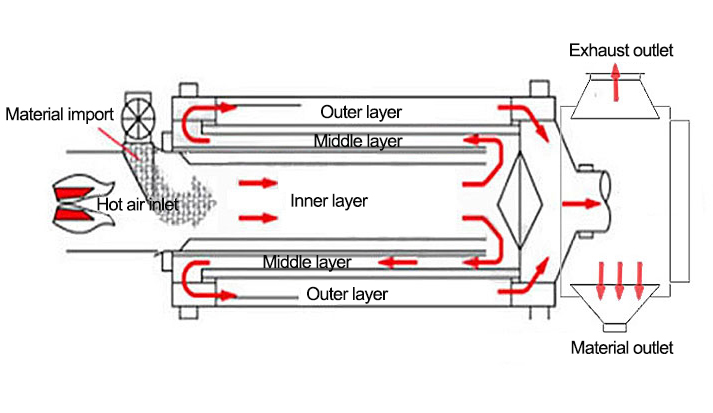

The cement dryer is a self-insulating circulation structure formed by an inner cylinder, a middle cylinder and an outer cylinder, so this new type of dryer is also called a three-drum dryer. The combined three-drum dryer has the characteristics of compact structure, small footprint, low energy consumption, high thermal efficiency, good material drying effect, and easy to realize automatic control. It is mainly used to dry granular materials within a certain humidity range, such as yellow sand used in the dry mortar industry, various specifications of molding sand used in the foundry industry, and blast furnace slag used in the building materials cement industry. According to the moisture requirements of different industries for dried materials, the moisture content of the dried materials can reach below 1-0.5%, which is an ideal product for various drying projects.

Product Performance

- 1Small footprint and low installation cost

The equipment has a compact structure and small footprint, which is half the footprint of a single-drum dryer with the same output. The civil engineering investment is reduced by about 60%, and the installation is convenient.

- 2Good wear resistance, sturdy and durable

The whole machine is made of wear-resistant steel plates, which are 3-4 times more wear-resistant than ordinary steel plates, with low maintenance rate and long service life.

- 3Reduce production processes and save costs

The discharge temperature is basically lower than 60 degrees, and it can be directly fed into the material warehouse without cooling in the cooling shed, saving production processes and production costs.

- 4Advanced technology, energy-saving and environmentally friendly

Adopting a new energy-saving technology--inlaid structure, and a special thermal design concept, it eliminates the heat loss of the wind tunnel, increases the heat exchange area and the evaporation intensity per unit volume, and has a good energy-saving effect. It is an environmentally friendly and energy-saving product that replaces traditional drying equipment.

Working Principle

The cement dryer is mainly composed of a feed end, a discharge end, a rotating cylinder, a support device, a transmission device, a hot air furnace, etc. Among them, the feed end and the discharge end are used for the raw materials and finished products entering and exiting the cement dryer respectively. The rotating cylinder is the main part of the cement dryer, which is used to accommodate the cement raw materials and dry them. The support device is used to support the rotating cylinder and make it rotate horizontally, the transmission device is used to drive the rotating cylinder to rotate, and the hot air furnace provides the heat source required by the cement dryer.

The cement raw materials are dried by the heat source provided by the hot air furnace. During operation, the cement raw materials enter the rotating cylinder from the feed end and gradually move to the discharge end as the rotating cylinder rotates. Inside the rotating cylinder, the cement raw materials are affected by the heat source provided by the hot air furnace, gradually lose moisture and become finished cement. The dried cement is discharged through the discharge end, completing the entire drying process.

Technical Parameters

| Equipment specifications | Daily output (t/d) | Evaporation moisture capacity (t/h) | Raw material moisture (%) | Dry material moisture (%) | Drying temperature (℃) | Total installed capacity (kw) | Equipment floor space (m2) |

|---|---|---|---|---|---|---|---|

| DLGT2010/3 | 144.5-63.5 | 1.850 | 35-50% | 12-15% | 270±30℃ | 78 | 8m×18m |

| DLGT2210/3 | 154.0-67.5 | 1.976 | 35-50% | 12-15% | 270±30℃ | 85 | 8m×18m |

| DLGT2212/3 | 187.5-75.9 | 2.40 | 35-50% | 12-15% | 270±30℃ | 90 | 8m×20m |

| DLGT2510/3 | 193.0-83.5 | 2.427 | 35-50% | 12-15% | 270±30℃ | 110 | 10m×18m |

| DLGT2512/3 | 227.0-100.0 | 2.912 | 35-50% | 12-15% | 270±30℃ | 125 | 10m×20m |

| DLGT2912/3 | 268.0-120.0 | 3.432 | 35-50% | 12-15% | 270±30℃ | 135 | 10m×22m |