Popular searched products:

Product Description

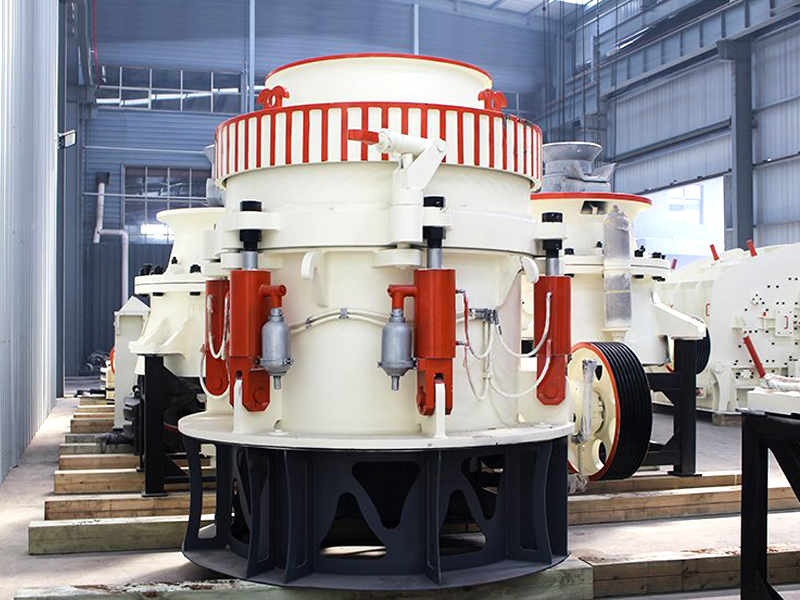

As you can tell from the name, the cone mobile crushing station is a new type of crushing equipment produced by combining traditional cone crushers and driving devices. The core crushing equipment is the cone crusher, which is a mobile crushing station with high productivity and good crushing effect. All components include: solid frame, hydraulic cone crusher, feeder, vibrating screen, conveyor belt, electric motor and control box, etc. It combines the advantages of a mobile crushing station and a cone crusher. It can directly select a site and drive directly to the site without transportation, and can directly reach the final product particle size. It is especially suitable for small crushing sites and is suitable for construction waste treatment and construction waste crushing.

Cone mobile crushing station

Product Performance

- 1Flexible configuration, agile walking

The vehicle-mounted integrated combination makes the work more flexible, is not restricted by the site, walks without damaging the ground, and has good mobility. Materials do not need to be transported.

- 2High output and reasonable material discharging

The structure is cleverly designed, and the layer-by-layer crushing chambers fully crush the materials. The power is strong and the output efficiency is high. Various finished products Reasonable particle size, few impurities, and high mixing rate.

- 3Intelligent and durable

Incorporating the concept of automatic control system, the operation is simpler, the parts are more carefully selected and the workmanship is more ingenious, making them more wear-resistant. Lifespan is greatly extended.

- 4Energy saving, consumption reduction, environmental protection and green

The motor is selected with high quality to save power consumption. The equipment has enhanced body sealing and is equipped with multiple dust removal equipment to reduce resistance. Green.

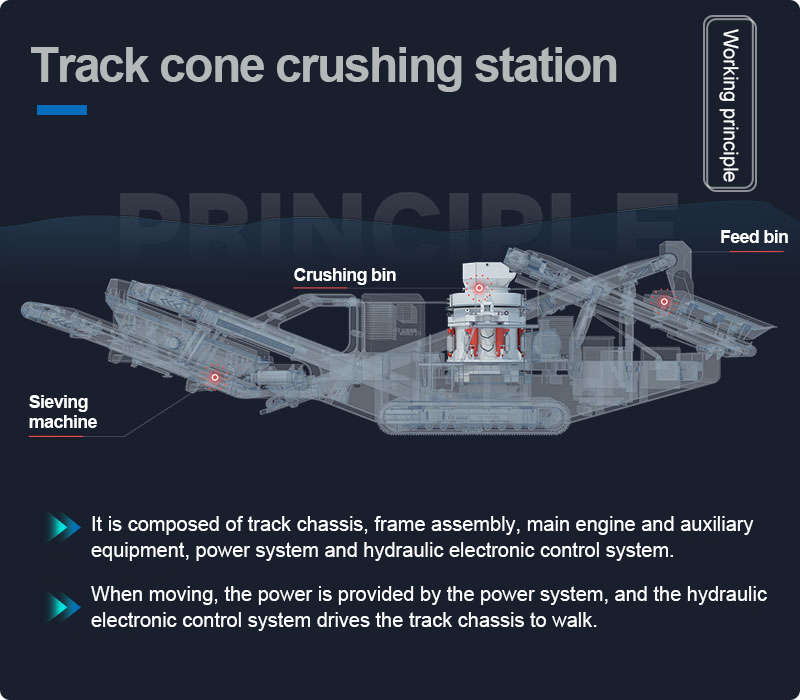

Working Principle

When the mobile cone crushing station is operating, the stones that meet the feed particle size are evenly transported to the cone crusher through the feeder. After preliminary crushing by the cone crusher, screening control is carried out, and only the qualified stones can enter the next step. The closed-circuit system can realize the cyclic crushing of materials. The finished materials are output by the conveyor for continuous crushing operations. The entire crushing process is smooth and productive, and the materials flow between each equipment at high speed.

Technical Parameters

| Standard model | Supporting equipment | Supporting equipment | External dimensions (mm) | ||

| Model | Feeding particle size (mm) | Processing capacity (t/h) | |||

| S-CS75 | 3YZK1848 | CS75 | ≤60 | 59-163 | 12600×2800×4400 |

| S-CS110 | 3YZK1860 | CS110 | ≤78 | 100-200 | 13800×3000×4400 |

| S-CS160 | 3YZK2160 | CS160 | ≤88 | 132-253 | 13800×3000×4400 |

| S-CS220 | 3YZK2160 | CS220 | ≤230 | 215-330 | 14500×3000×4500 |

| S-Q300 | 3YZK1848 | SQ300 | ≤60 | 105-205 | 12600×2800×4400 |

| S-Q400 | 3YZK1860 | SQ400 | ≤230 | 235-575 | 13800×3000×4400 |

| S-Q500 | 3YZK2160 | SQ500 | ≤240 | 304-640 | 14500x3000x4600 |

| S-H420 | 3YZK1848 | SH420 | ≤240 | 85-170 | 12600×2900×4400 |

| S-H430 | 3YZK1860 | SH430 | ≤360 | 120-345 | 13800×3000×4500 |

| S-H440 | 3YZK2160 | SH450 | ≤450 | 255-605 | 14800×3200×4600 |

| S-HP100 | 3YZK1860 | SHP100 | ≤40 | 75-140 | 13800×2900×4300 |

| S-HP200 | 3YZK2160 | SHP200 | ≤85 | 145-250 | 14200×3000×4500 |

| S-HP300 | 3YZK2160 | SHP300 | ≤230 | 220-440 | 16500×3200×4600 |

| S-PF1214 | 3YZK1860 | PF1214 | ≤300 | 100-200 | 14500×2900×4500 |

| S-PF1315 | 3YZK2160 | PF1315 | ≤350 | 130-280 | 15200×3000×4500 |

| S-PF1320 | 3YZK2460 | PF1320 | ≤500 | 180-400 | 15200×3000×4500 |

| S-S1860 | 3YZK1860 | ≤400 | 65-586 | 10500×2700×4200 | |

| S-S2160 | 3YZK2160 | ≤400 | 81-720 | 10500×3000×4500 | |

| S-S2460 | 3YZK2460 | ≤400 | 100-810 | 10500×3200×4500 | |