Popular searched products:

Product Description

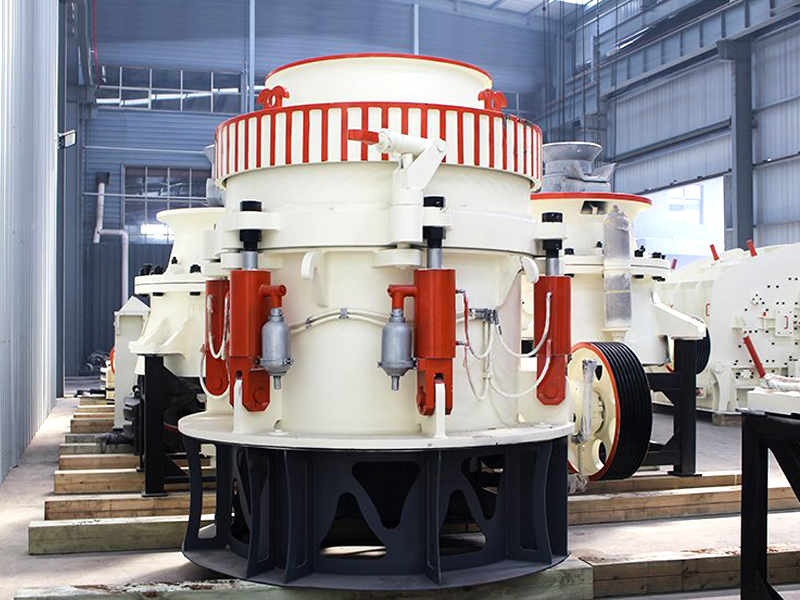

HP multi-cylinder hydraulic cone crusher has multiple hydraulic cylinder devices, evenly distributed around the casing, playing a locking role, used to control discharge and clearance, and can provide iron protection, hence the name, referred to as multi-cylinder Cone broken. The unique design of the multi-cylinder hydraulic cone machine gives full play to the advantages of laminated crushing, greatly increases the interaction between materials, realizes selective crushing of materials, optimizes the particle shape of the stone, and makes the particle distribution more uniform. HP multi-cylinder hydraulic cone crusher operates smoothly, has high safety, convenient clearance, and powerful fine crushing. It is widely used in mining, construction, water conservancy, chemical industry, ceramics, cement and building materials and other industries.

Real shot

Product Performance

- 1High crushing efficiency, low investment

Fixed-axis structural design, large crushing force, improved crushing efficiency, increased work output per unit time, and reduced equipment infrastructure invest.

- 2The finished material tastes good

Based on the principle of laminated crushing chamber, the finished material has uniform particle size and is in the shape of a cube, which reduces equipment energy consumption and improves the taste of the discharged material.

- 3High degree of intelligence, safe production

The fully automatic control system of PLC + touch screen has a high degree of intelligence, human-machine isolation control, and safer production.

- 4Easy operation and strong applicability

All parts can be disassembled and maintained from the top or side without disassembling the frame, bolts, and hydraulic motors. The discharge port makes the whole machine easy to operate and adapts to a wide range of product particle size requirements.

- 5Thin oil lubrication, long service life

The crushing cavity adopts high-performance non-contact labyrinth seals, which improves the reliability of blocking dust and reduces Iron pollution and equipment wear cycles, hydraulic lubrication combined oil station, small size, simple wiring, improve the service life of the equipment.

Working Principle

The ore falls into the machine from the ore feeding port through the distribution plate. The distribution plate is installed on the upper end of the vertical shaft. Due to the rotation of the vertical shaft, it vibrates and distributes the ore evenly around the cone. With the help of the hinge rod and hinge attached to the handle, the fixed cone can be raised or lowered to adjust the width of the ore discharge port. All parts are made of cast steel. The working surfaces of the moving cone and the fixed cone are lined with manganese steel lining plates to protect the cones from wear. The lining plates can be replaced after wear. When replacing, molten steel is poured into the space between the lining plates and the cone surface. The lead makes them tightly bonded.

Technical Parameters

| Model | Cavity type | Feeding port size (mm) | Tight edge feed opening size (mm) | Minimum discharge opening size (mm) | Motor power (kw) | Output (t/h) | Weight (t) |

| HP100 | C1 (extra thick) | 175 | 140 | 19 | 4P 100 | 45-140 | 8.4 |

| C2(coarse) | 125 | 105 | 13 | ||||

| M(中) | 100 | 70 | 10 | ||||

| F1(fine) | 71 | 50 | 9 | ||||

| F2 (ultra-fine) | 33 | 20 | 6 | ||||

| HP200 | C2(coarse) | 235 | 190 | 19 | 4P 160 | 90-250 | 10.4 |

| M(中) | 171 | 120 | 16 | ||||

| F1(fine) | 150 | 95 | 13 | ||||

| F2 (ultra-fine) | 116 | 70 | 8 | ||||

| HP300 | C1 (extra thick) | 265 | 230 | 25 | 4P 220 | 115-440 | 18.1 |

| C2(coarse) | 240 | 210 | 20 | ||||

| M(中) | 190 | 150 | 15 | ||||

| F1(fine) | 145 | 105 | 11 | ||||

| F2 (ultra-fine) | 120 | 80 | 8 | ||||

| HP400 | C1 (extra thick) | 360 | 290 | 30 | 4P 315 | 140-630 | 25 |

| C2(coarse) | 310 | 250 | 25 | ||||

| M(中) | 260 | 196 | 20 | ||||

| F1(fine) | 182 | 110 | 13 | ||||

| F2 (ultra-fine) | 135 | 90 | 10 | ||||

| HP500 | C1 (extra thick) | 370 | 330 | 38 | 4P 400 | 175-790 | 36 |

| C2(coarse) | 320 | 290 | 28 | ||||

| M(中) | 245 | 210 | 22 | ||||

| F1(fine) | 180 | 130 | 13 | ||||

| F2 (ultra-fine) | 150 | 95 | 10 | ||||

| HP800 | C1 (extra thick) | 450 | 352 | 38 | 4P 830 | 260-1200 | 68.5 |

| C2(coarse) | 373 | 298 | 32 | ||||

| M(中) | 340 | 275 | 25 | ||||

| F1(fine) | 280 | 230 | 16 | ||||

| F2 (ultra-fine) | 235 | 150 | 10 |