Popular searched products:

Because a problem often encountered in sand washing operations is the serious loss of fine sand, which causes losses to the company and affects the sand gradation. The emergence of the fine sand recovery machine can very well recover the large amount of fine sand lost by the sand washing machine in the traditional manufacturing process. in the sand industry. It solves users' troubles and is widely used. Regarding fine sand recovery machines, this article has compiled some of the most common problems with fine sand recovery machines in the past. If you also have trouble in this regard, you may wish to refer to it.

1. Should the fine sand recovery machine be used in conjunction with the sand washing machine?

Answer: In the sand and gravel production line, the fine sand recovery machine is mainly used after the sand washing machine (used in conjunction with the sand washing machine) to recover a large amount of fine sand lost by the traditional sand washing machine. The sand making industry (up to more than 20% in serious cases), while improving economic benefits, also reduces the cost of tailings treatment and the pollution and damage to the environment caused by the loss of fine sand.

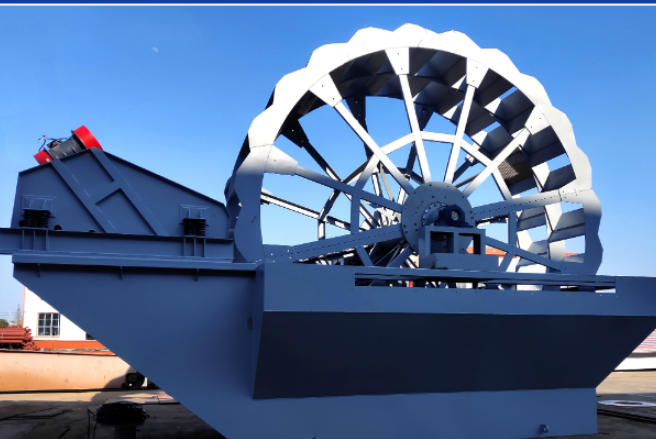

2. What are the structural components of the fine sand recovery machine? What are the main functions?

Answer: The fine sand recovery machine mainly consists of a sand washing tank, a mortar pump, a motor, a cyclone separator, a vibrating screen, a return box, etc. When used in a sand and gravel plant, its main function is to wash sand and separate sediment, so it is also called fine sand recovery machine. Sand dewatering machine, sediment separator, sediment extraction machine; when used in mineral processing plants, the main function is to recover tailings, so it is also called tailings machine. Mining recycling machine.

3. What is the difference between a dewatered fine sand recovery machine and an ordinary fine sand recovery machine?

Answer: The dewatering fine sand recovery machine has two functions: dehydration and recovery. It performs secondary cleaning and dehydration operations on the finished sand washed out by the sand washing machine, and performs fine sand recovery operations on the waste water discharged from the sand washing machine.

Dehydration operation area: It consists of a vibration motor and a dehydration screen; the finished sand from the sand washing machine directly enters the dehydration screen for secondary cleaning, classification, and dehydration.

Recycling operation area: composed of vacuum high-pressure pump, motor, separator, return water tank, and cleaning tank; the wastewater discharged from the sand washing machine (also known as mud-sand-water mixture) enters the cleaning tank and is transported to the separator for processing by the vacuum high-pressure pump. The sediment is separated and extracted to collect fine sand. The fine sand enters the dehydration screen through the grit nozzle for dehydration. Other impurities enter the return water tank through the overflow port of the separator and are discharged.

Sand washing operation, fine sand recovery machine, fine sand recovery machine frequently asked questions

4. What is the main difference between fine sand recovery machine and sand washing and recovery integrated machine?

Answer: Simply put, the integrated sand washing and recycling machine is divided into a sand washing part and a fine sand recycling part. It consists of two parts: an impeller sand washing machine and a fine sand recovery machine (generally a fine sand recovery machine or a dewatering fine sand recovery machine, or a multi-layer dewatering screen according to the sand making requirements), which is easy to distinguish.

5. What is the reason for the sudden decrease in recycling volume during use?

Answer: If you find that the amount of fine sand recovered is significantly reduced or there is a small amount of sand leakage, you should check whether the screen is damaged or whether the bolts fixing the screen are loose. Faced with this situation, the solution is to replace the screen or tighten the bolts. When the screen wear is too serious, it will cause the screen to break, resulting in reduced recycling efficiency. The screen should be inspected regularly and replaced promptly after wear and tear.

6. In addition to the fine sand recovery machine, what other methods can be used to prevent the loss of fine sand?

Answer: You can also use methods such as multi-stage sedimentation tanks, equipped with dewatering screens, adding chemicals, and equipped with integrated sand washing and recovery machines for fine sand recovery. When configuring the integrated sand washing and recycling machine, there is no need to add a separate sand washing machine.

Related Reading

- What is the production cost of fine sand recycling machine? What are the key factors that affect the price of fine sand recovery machines?

- Where can I buy a fine sand recycling machine that is reliable? Which manufacturers sell fine sand recycling machines cheaply?

- Regarding the price of mobile sand making machines, manufacturer recommendations, and sand blasting effects, this article has everything you want to know!

- What is machine-made sand? Why is machine-made sand so popular? What are the advantages of machine-made sand?

Product show

Product

Source:

Source: Time:2024/04/26 09:49:39

Time:2024/04/26 09:49:39