Popular searched products:

Product Description

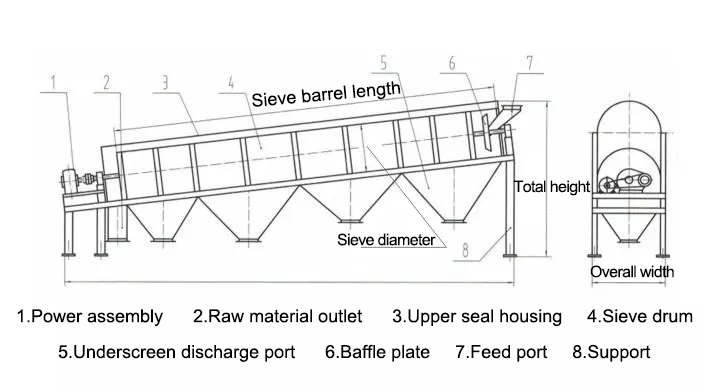

As an efficient and practical screening equipment, trommel screen is widely used in construction, roads and bridges, water conservancy projects and other fields. Its unique drum design and screening principle make the sand screening process faster and more accurate, effectively improving work efficiency and reducing the labor intensity of manual sand screening.

The main components of the drum screen include the feed port, drum screening device, discharge port and driving device. When working, the raw materials enter the inside of the drum through the feed port. Under the rotation of the drum, the raw materials are affected by centrifugal force and gravity to achieve the screening process. The screened materials are discharged through the discharge port, and materials of different particle sizes are separated, achieving rapid screening of materials.

Product Performance

- 1Good screening effect

The finished screen adopts strict installation inclination angle, the screen holes are not easy to be blocked, and the screening effect is good and the screening efficiency is high.

- 2High sorting accuracy

The inner wall of the drum is equipped with a flexible plate, which can lift the material particles so that the material particles of different particle sizes can be as small as possible. have the opportunity to contact the sieve holes, which can effectively improve the sorting accuracy.

- 3Centralized lubrication, fast

Adopting advanced centralized lubrication system, lubrication is convenient and fast, and the maintenance workload is small.

- 4Good sealing, good for environmental protection

The screening cylinder can be closed, easy to seal and collect dust; the cylinder is covered by a dust-proof sealing cover to facilitate production The process is almost free of dust and noise pollution.

Working Principle

When working, the motor is connected to the drum device through the reducer, so that the drum device is installed at an angle and rotates around its axis. When the material enters the drum device, due to the tilt and rotation of the drum, the material will flip and roll inside the drum. The larger particles are filtered out by the screen inside the drum, while the smaller particles fall through the screen into the outlet below. Material mouth. In addition, due to the turning and rolling of materials, materials stuck in the screen holes can be ejected, thereby preventing the screen holes from being blocked.

The screen of the trommel screen is usually composed of multiple layers of screens with different apertures to achieve the separation of materials with different particle sizes. At the same time, the rotation speed and inclination of the drum can be adjusted as needed to adapt to the screening requirements of different materials.

Technical Parameters

| Model | Output (m³/h) | Power (kw) | |

| Mesh hole (2mm) | Mesh hole (30mm) | ||

| YTS1230 | 12 | 100 | 5.5 |

| YTS1240 | 14 | 120 | 5.5 |

| YTS1250 | 15 | 140 | 5.5 |

| YTS1530 | 18 | 150 | 5.5 |

| YTS1540 | 18 | 150 | 7.5 |

| YTS1550 | 20 | 180 | 11 |

| YTS1560 | 22 | 200 | 11 |

| YTS2040 | 25 | 250 | 15 |

| YTS2050 | 30 | 300 | 15 |

| YTS2060 | 35 | 350 | 18.5 |