Popular searched products:

Product Description

Rod mills are available in dry and wet types. Users can choose according to their actual conditions. The company adopts advanced controllable feeding and discharging technology. According to the actual grinding materials, suitable grinding bodies should be used. The traditional surface contact is changed to line contact, so that the discharge particle size is more uniform and the output is higher. It is widely used in grinding operations with relatively high requirements for the uniformity of the finished product after grinding in industries such as refractory materials, chemicals, metallurgy, and glass. In recent years, it is also used in the sand making industry for building sand. The characteristic of rod mill is that during the grinding process, the grinding medium is in line contact with the ore, so it has a certain selective grinding effect. The product particle size is relatively uniform, and there are fewer over-crushed ore particles. When used for coarse grinding, the processing capacity of rod mill is greater than that of ball mill of the same specification. And vice versa.

Real shot display of ore dressing rod mill

Product Performance

- 1Adopt automatic centralized lubrication system

Adopt automatic centralized lubrication system to replace the original thin oil lubrication station. Large mills do not need to be equipped with expensive high and low pressure thin oil lubrication stations, avoiding thin oil pollution, saving 70% of oil costs per year, while reducing equipment failure rate and operator maintenance costs, and improving the production efficiency of the whole equipment.

- 2Adopt spherical roller bearings

The rod mill adopts spherical roller bearings to replace traditional Babbitt alloy bearing supports, with low running resistance. Under the same model and the same production capacity, it can save 10%~20% of electricity, and under the same power, it can increase production capacity by 10%~20%.

- 3Reliable drive device and multifunctional configuration

The entire series of mills are equipped with large gear jet lubrication system and slow drive device. Large mills are also equipped with high-voltage motors, pneumatic clutches, one-to-four lifting devices, automatic rod adding devices, etc., which can also be selected according to user needs.

Working Principle

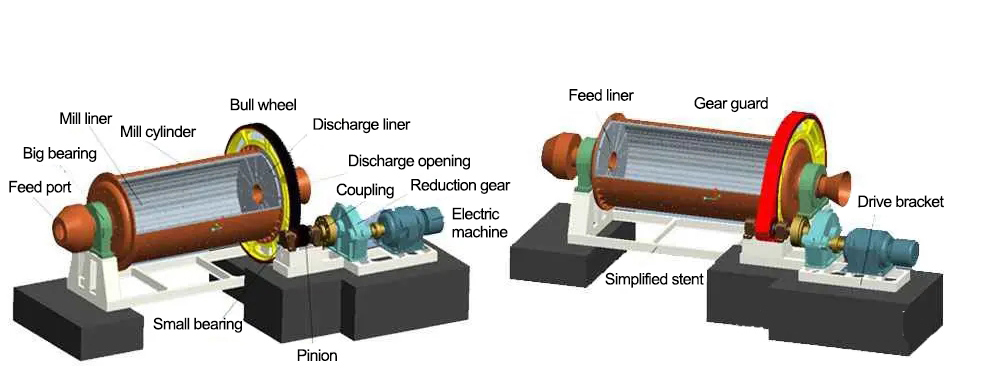

The working principle of rod mill is the same as that of ball mill, that is, the raw material is fed into the hollow circle through the hollow shaft neck for grinding. The hollow cylinder is filled with grinding media of different diameters. When the cylinder rotates at a certain speed around the horizontal axis, under the combined action of centrifugal force and friction, the media and raw materials in the cylinder reach a certain height as the cylinder rotates. When their own gravity is greater than the centrifugal force, they will break away from the inner wall of the cylinder and fall or roll down, and the ore will be crushed due to the impact force. At the same time, during the rotation of the mill, the sliding of the grinding media against each other will also produce a grinding effect on the raw material. The ground material is discharged through the hollow shaft at the other end. As the material is continuously fed in, pressure is generated to move the material in the cylinder from the feeding end to the discharging end. In wet grinding, the water flow carries away the material; in dry grinding, the air flow drawn out of the cylinder carries away the material. In the mill, the height to which the grinding media is lifted and the trajectory of its fall are related to the cylinder speed, the number of media and the form of the liner.

The working principle of the rod mill is as follows: the material to be ground enters the cylinder through the feeding part and the feeding part; the motor drives the transmission system, drives the cylinder to rotate through the large gear, and the steel rods and materials inside the cylinder rise to the limit height with the cylinder lining plate and then fall down, crushing and grinding the materials in the cylinder; the materials are squeezed and ground by the steel rods, and are discharged through the discharge port after reaching the qualified fineness.

Technical Parameters

| Model specification | Diameter (mm) | Length (mm) | Drum speed (r/min) | Feeding size (mm) | Discharging size (mm) | Output (t) | Power (kw) | Rod loading amount |

| GMB1835 | φ1800 | 3500 | 22.8 | ≤25 | ≤5 | 20-50 | 160 | 13 |

| GMB2136 | φ2100 | 3600 | 20.9 | ≤25 | ≤5 | 30-70 | 210 | 18 |

| GMB2145 | φ2100 | 4500 | 20.9 | ≤25 | ≤5 | 50-80 | 250 | 20 |

| GMB2436 | φ2400 | 3600 | 19 | <20 | ≤5 | 60-120 | 280 | 21 |

| GMB2736 | φ2700 | 3600 | 17.5 | <20 | ≤5 | 100-220 | 400 | 24 |

| GMB2745 | φ2700 | 4500 | 17.5 | <20 | ≤5 | 120-250 | 500 | 27 |

| GMB3245 | φ3200 | 4500 | 16 | <20 | ≤5 | 300-450 | 800 | 50 |

| GMB3645 | φ3600 | 4500 | 15 | <20 | ≤5 | 430-580 | 1000 | 55 |