Popular searched products:

Product Description

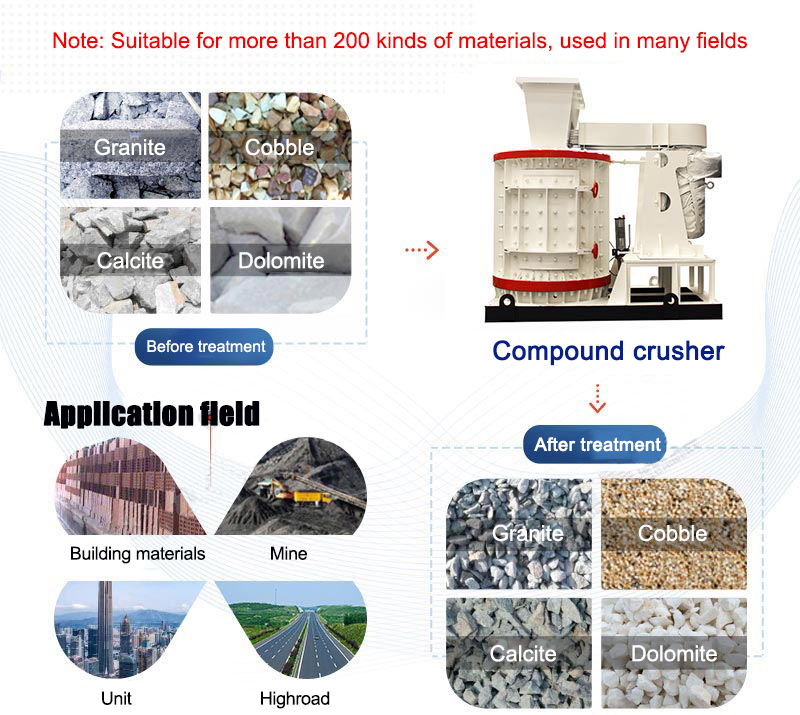

Compound crusher, also known as vertical sand making machine, compound sand making machine, and vertical shaft sand making machine, is composed of technical engineers who combine the new technologies of similar crushers at home and abroad to optimize the main technical parameters according to the actual situation and user needs. The new fine crushing and coarse crushing machines developed with improved structural characteristics have outstanding advantages such as smooth operation, large crushing force, large output, good particle size of finished products, small amount of abrasion, low energy consumption, good sealing, and easy maintenance.

Product Performance

- 1Large processing capacity

Change the previous connection method of the plate hammer and adopt a rigid connection. When working, the inertia of the rotor is used to impact the material, which not only The crushing effect is achieved, greater speed and function are obtained, and the processing capacity of the equipment is increased.

- 2Less damage to accessories

Abandon the traditional integral hammer head structure design and adopt a combined structure design, which is more conducive to hammering and crushing materials. The service life of the hammer head is greatly extended, thereby effectively reducing production costs and reducing the impact of equipment shutdown.

- 3Environmental protection and energy saving

The machine is equipped with a dust-proof plate inside, which has good sealing performance and avoids the splashing of broken small materials, with less dust. The working noise is low, which effectively improves the working environment at the construction site.

- 4High sand production rate

The special structure and production method make this composite crusher have a very high sand production rate, especially 800 and 1000 The sand making rate of this model is very high. Although there are no sieves, the discharge particle size is very fine. Sand making plants with low requirements can directly produce sand. Only those with higher requirements are equipped with a screening machine.

Working Principle

The lumpy ore falls from the feed hopper onto the upper throwing plate in the upper crushing chamber. With the help of the centrifugal force of the throwing plate, the material is thrown to the inner wall of the cylinder, and violently collides with the impact plate installed on the inner wall. At the same time, the material The materials collide with each other, causing them to break or produce a large number of hairline cracks. Then, after the material enters the conical rotor cavity, it falls in a spiral shape in the conical space. After stamping and extrusion, the cracked ore is further broken. Due to the slope between the conical rotor and the lining plate, smaller materials are prompted to migrate downward, achieving automatic classification crushing from large to small. The materials are blowed by the hammer in the conical rotor cavity. The high-speed moving block materials collide with the impact plate again. The material flows hit each other to make them crushed through blowing, impact, shearing and extrusion, thus improving the crushing efficiency.

Technical Parameters

| Model | Rotor diameter (mm) | Cylinder height (mm) | Spindle speed (r/min) | Discharge particle size (mm) | Production capacity (t/h) | Motor model | Outline dimensions (mm) |

| 800 | 650 | 800 | 1350 | 0-5 | 5-15 | 30 | 2200x860x1980 |

| 1000 | 800 | 850 | 970 | 0-5 | 10-30 | 55 | 2700x1160x2000 |

| 1250 | 1000 | 850 | 740 | 0-5 | 20-60 | 75 | 2800x1400x2730 |

| 1500 | 1250 | 1000 | 650 | 0-5 | 110-132 | 110 | 3100x1900x2300 |

| 1750 | 1560 | 1410 | 600 | 0-5 | 40-100 | 185-200 | 3350x2100x2800 |

| 2000 | 1740 | 1550 | 500 | 0-5 | 80-200 | 220-250 | 4100x2660x2670 |