Popular searched products:

Product Description

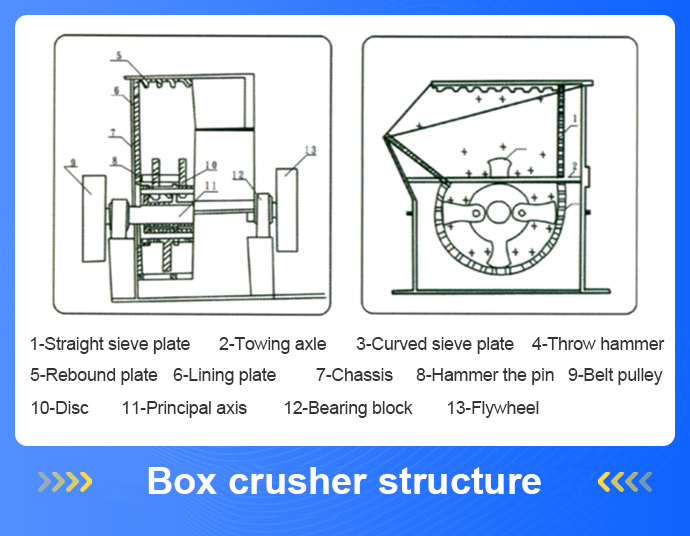

The box crusher is a new generation of crushing machinery product manufactured by our company after absorbing advanced domestic and foreign technologies, combined with the mechanical principles of various other crushers that use hammers to crush stones, and optimized design. It is mainly suitable for Primary and secondary crushing of various materials with compressive strength below medium to upper hardness. The box crusher changes the method of using grate bars to control the size of discharged particles, which reduces the wear of the hammer head in the crushing cavity and increases the life of the hammer head by 4-6 times. Each pair of hammer heads can crush 30,000-40,000 tons. A major breakthrough in crushing technology has been achieved.

Product Performance

- 1Large crushing ratio, high yield rate

Large crushing ratio, high yield rate, granular products account for about 85%, fully meeting the usage requirements

p>

- 2Simple structure and easy maintenance

The frame part of the box crusher is divided into three parts. You only need to open the rear casing of the crusher. , you can perform inspection and maintenance operations such as replacing the blow hammer, crushing plate, and lining plate.

- 3Parts are wear-resistant and have a long service life

The hammer head, grate plate and counterattack plate are made of highly wear-resistant materials and have a long service life.

- 4Advanced technology and reliable operation

The monitoring system of the box crusher can monitor the operating status of the crusher at any time, and the monitoring signal can be communicated with the main The control system is interlocked to ensure the safe and reliable operation of the machine.

Working Principle

The working principle of the box crusher is mainly based on mechanical energy conversion and mutual collision between materials. Its working process is as follows:

1. The material enters the crushing chamber from the feed port. At this time, the high-speed rotating turntable is supported by the horizontal bar, and the hammer head quickly hits the material.

2. Under the action of high-speed centrifugal force, the materials produce high-speed impact and high-density crushing.

3. After the stones hit each other, they will also form a vortex movement between the turntable and the casing, causing multiple hits, frictions, and crushings.

4. When the particle size of the material is smaller than the gap of the sieve plate, it will be discharged from the lower part of the machine.

In addition, the structure of the box crusher includes the crushing chamber, rotor, impact plate, feed port and discharge port. The crushing chamber is its main working area, which includes the rotor and impact plate. The rotor is installed on the shaft, and the rotation of the shaft is driven by a power source such as a motor, and the impact plate is installed and fixed above the crushing chamber.

Technical Parameters

| Model | Roller diameter (mm) | Roller length (mm) | Feeding particle size (mm) | For stone materials | Output (t/h) | Power (kw) |

| 700x1000 | 700 | 1000 | ≤500 | Pressure 300MPa various types of stone | 50-80 | 45-55 |

| 1000x1000 | 1000 | 1000 | ≤800 | 70-100 | 75-90 | |

| 1000x1200 | 1200 | 1000 | ≤800 | 90-120 | 90-110 | |

| 1200x1200 | 1200 | 1200 | ≤900 | 130-160 | 110-132 | |

| 1400x1400 | 1400 | 1400 | ≤1000 | 190-210 | 132-160 | |

| 1600x1600 | 1600 | 1600 | ≤1000 | 250-300 | 160-210 | |

| 1800x1800 | 1800 | 1800 | ≤1200 | 300-400 | 210-280 |