Popular searched products:

Product Description

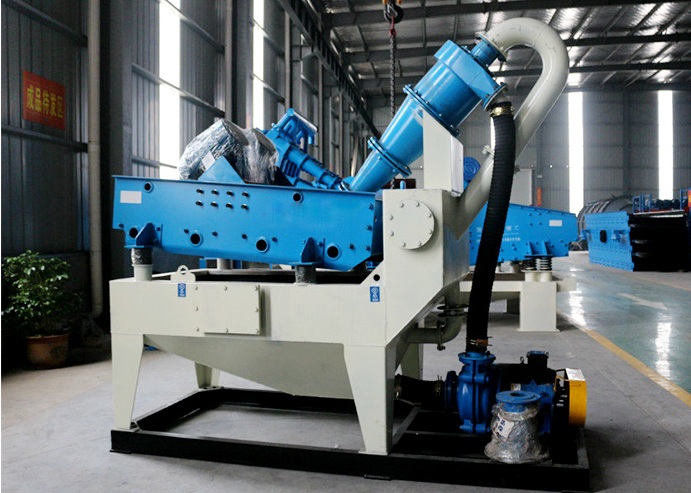

PG double roller crusher is an environmentally friendly crushing equipment with low dust and low noise. It is mainly composed of rollers, roller support bearings, compression and adjustment devices, and driving devices. A wedge-shaped or gasket adjustment device is installed between the two rollers, which can flexibly adjust the discharge. The crushed materials are cube-shaped and have fine particle size. They are widely used in metallurgy, chemical industry, electric power, transportation and other fields. Medium and fine crushing of soft ores.

Product Performance

- 1The mobile chassis is reasonably designed and easy to move

The mobile crusher can use an independent mobile chassis according to different crushing equipment in the operating area or on the road. Flexible mobility

- 2Reasonable and compact structure, strong applicability

The mobile crusher is designed with multiple functions such as feeding, conveying, and crushing, and is suitable for any site job run

- 3Low operating cost, stable performance

Applicable to a wide range of materials, reducing transportation costs, high production efficiency and strong stability

- 4Low energy consumption, energy saving and environmental protection

The special working principle of the mobile crusher makes it work with low energy consumption, low carbon, energy saving, Environmental protection

- 5Excellent material selection and durability

Mobile crusher accessories are made of super wear-resistant materials, which greatly extends the service life of the equipment

Working Principle

During operation, the crushed materials fall between the two rollers through the feeding port for squeezing and crushing, and the finished products are discharged from the lower outlet. A wedge or gasket adjustment device is installed between the two rollers of the double-roller crusher. There is an adjustment bolt at the top of the wedge device. When the adjustment bolt block is pulled upward, the wedge pushes the movable roller away from the fixed wheel. The gap becomes larger. When the wedge moves downward, the gap between the two movable rollers becomes smaller under the action of the compression spring, and the discharge granularity becomes smaller. The gasket device adjusts the discharge particle size by increasing or decreasing the quantity or thickness. When the gasket is added, the gap between the two rollers becomes larger, and when the gasket is reduced, the gap becomes smaller.

Technical Parameters

| Model | Roller diameter (mm) | Feeding particle size (mm) | Discharge particle size (mm) | Output (t/h) | Power (kw) |

| 2PG400x250 | φ400 | <25 | ≤3 | 5-10 | 5.5x2 |

| 2PG450x500 | φ450 | <30 | ≤3 | 8-20 | 7.5x2 |

| 2PG610x400 | φ610 | <30 | ≤3 | 13-35 | 15x2 |

| 2PG610x750 | φ610 | <30 | ≤3 | 16-40 | 22x2 |

| 2PG750x500 | φ750 | <30 | ≤3 | 16-40 | 22x2 |

| 2PG800x600 | φ800 | <30 | ≤3 | 20-40 | 30x2 |

| 2PG800x800 | φ800 | <30 | ≤5 | 20-50 | 37x2 |

| 2PGY1000x800 | φ1000 | <30 | ≤5 | 40-70 | 55x2 |

| 2PGY1200x1000 | φ1200 | <30 | ≤5 | 60-100 | 90x2 |

| 2PGY1200x1200 | φ1200 | <30 | ≤5 | 80-130 | 110x2 |

| 2PGY1500x1000 | φ1500 | <30 | ≤5 | 100-150 | 132x2 |

| 2PGY1500x1200 | φ1500 | <30 | ≤5 | 150-200 | 160x2 |

| 2PGY1800x1000 | φ1800 | <30 | ≤5 | 220-300 | 200x2 |

| 2PGY2000x1200 | φ2000 | <30 | ≤5 | 300-400 | 250x2 |

| The above data is for reference only and may vary depending on conditions. | |||||