500 tons per hour limestone crushing production line

Production Capacity:500t/h

Processing materials:limestone

Power Consumption:No data

Production Capacity:500t/h

Processing materials:limestone

Power Consumption:No data

Global Heavy industry quality is good

This is a limestone crushing production line located in Yili, Xinjiang!

Material: Limestone

Capacity: 500 tons/hour

Finished product: fine gravel aggregate

Finished product size: 0-5mm/10-20mm/16-31.5mm

Use of finished product: used in surrounding mixing stations and surrounding high-speed high-speed rail projects

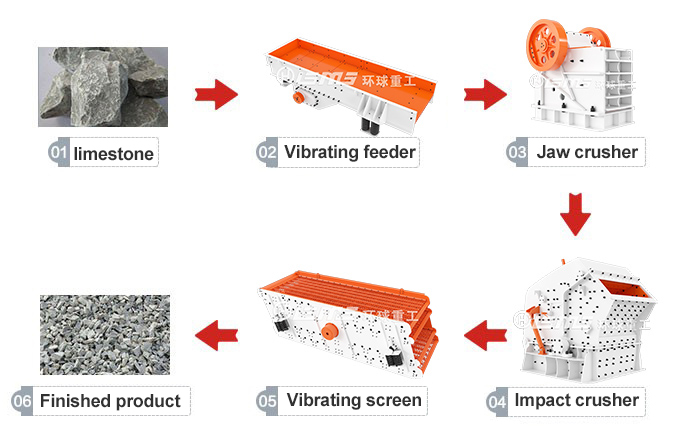

Equipment configuration: primary crushing stage: one vibrating feeder and one jaw crusher; medium and fine crushing stage: one impact crusher; screening stage: two vibrating screens.

Real shot on site Shoot

Real shot on site Shoot

1. This production line meets customers’ increasing requirements for the quality of finished limestone products. According to different process requirements, various types of equipment are combined to meet customers’ different process requirements and bring considerable economic benefits to customers.

2. The entire production loss is small, the profit is large, and the output is increased by 25%-40%. The finished products are mostly cube-shaped and have uniform particles, which can achieve higher economic benefits.

3. This limestone crushing production line can achieve a high degree of automation, low operating costs, high crushing rate, less pollution, and easy maintenance.

4. During the entire crushing production process, the dust is very small, the sealing performance is good, and it meets the national dust emission standards.

The limestone is uniformly fed by the vibrating feeder to the jaw crusher for primary crushing. The materials after primary crushing and the fine materials screened by the vibrating feeder are transported to the impact crusher by a belt conveyor. The impact crusher crushes (medium and fine crushing), and then uses a circular vibrating screen to screen the limestone crushed by the impact crusher: the larger particles of limestone are returned to the impact crusher for crushing again, and the qualified materials are classified and processed according to needs. It is transported by conveyor belt to different storage piles for storage or directly transported by truck to the construction site.

The limestone production line designed by Global Heavy Industry for us has reasonable equipment configuration and low investment cost. The production line can be operated remotely and automatically during operation. It is easier and more efficient for us to operate. After crushing, the finished stone particles have good quality, uniformity and better gradation. It’s reasonable. Now the finished limestone products I process here are also welcomed by many customers.