Popular searched products:

Product Description

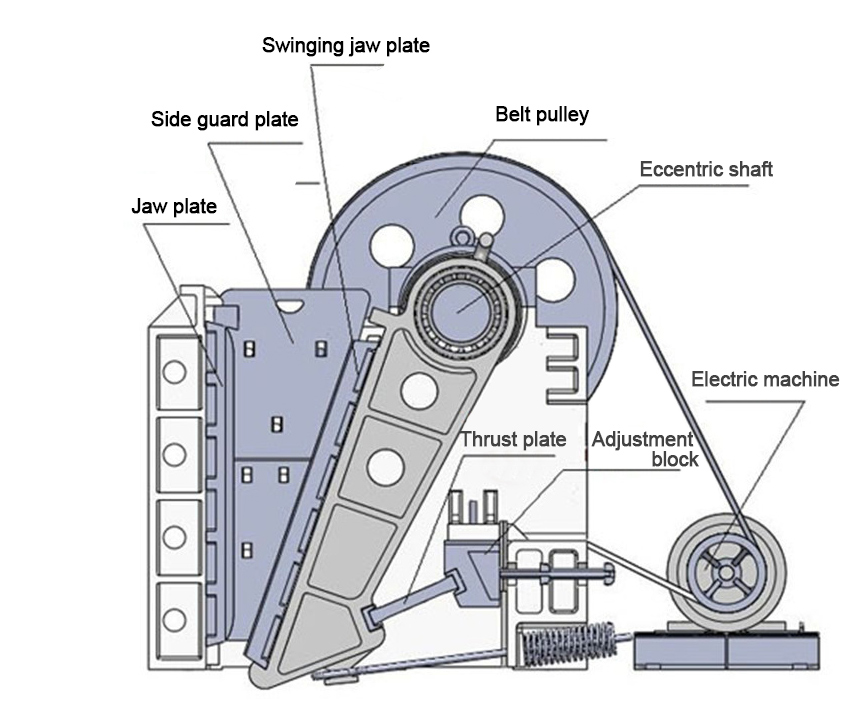

The structure of the jaw crusher is mainly composed of a movable jaw plate, a fixed jaw plate and an eccentric shaft. When the eccentric shaft rotates, the movable jaw plate mainly bears the squeezing effect of the material, while the fixed jaw plate mainly bears the sliding cutting effect of the material. As a component with a high jaw wear rate, the selection of jaw plate material is related to the user's cost and benefit.

Product Performance

- 1Unique crushing cavity type

Adopts "V" symmetrical crushing cavity design. The crushing cavity is deep, the bite angle is small, the stroke is large, and the processing It has greater capacity, lower energy consumption and greater crushing ratio.

- 2High crushing output

The higher rotation speed increases the throughput and material crushing frequency, greatly increasing the output.

- 3Easy to operate and transport

The integrated motor installation, motor base and crushing frame are integrated to reduce the space of the crusher and the length of the V-belt.

- 4Good movable jaw assembly

The movable jaw assembly adopts a forged heavy-duty eccentric shaft and high-quality heavy-load spherical roller bearings to ensure The movable jaw assembly has impact resistance and high stability; the labyrinth seal and centralized lubrication system ensure that the bearing grease is not contaminated, making the lubrication more effective and stable.

Working Principle

The working mechanism of the jaw crusher is composed of a working chamber composed of a movable jaw and a fixed jaw. The movable jaw and the fixed jaw bear huge crushing force and friction of the material, and are easily worn. In order to protect the jaw plate, they are usually placed The surfaces of the movable jaw and fixed jaw are equipped with wear-resistant lining plates, which are also called crushing tooth plates. The surface of the crushing tooth plate is usually made into a tooth shape, and the angle of the tooth peak of the crushing plate is 90° to 120°. The size is determined by the nature and blockiness of the material to be crushed. When crushing large pieces of material, the angle should be larger; When breaking small pieces of materials, the angle can be smaller. The size of the tooth pitch depends on the particle size of the product, and is usually approximately equal to the width of the discharge port. The ratio of tooth height to tooth pitch can be 1/2 to 1/3. When working, the upper and lower parts of the crushing tooth plate wear at different speeds. The lower part wears faster than the upper part. When the jaw crusher is working, the crushing tooth plate is in direct contact with the material and bears huge crushing force and friction of the material. Function, the service life of the crushing tooth plate is directly related to the working efficiency and production cost of the jaw crusher. Therefore, it is particularly important to extend the service life of the crushing tooth plate of the jaw crusher.

Technical Parameters

| Model | Feeding port size (mm) | Maximum feeding particle size (mm) | Discharge port adjustment range (mm) | Processing capacity (t/h) | Eccentric shaft speed (r/min) | Motor power (kw) |

| PE-150×250 | 150×250 | 125 | 10-40 | 1-3 | 250 | 5.5 |

| PE-200×300 | 200×300 | 180 | 15-50 | 2-6 | 260 | 7.5 |

| PE-200×350 | 200×350 | 180 | 18-70 | 3-10 | 260 | 11 |

| PE-250×400 | 250×400 | 210 | 20-60 | 5-20 | 300 | 15 |

| PE-400×600 | 400×600 | 340 | 40-100 | 16-60 | 275 | 30 |

| PE-500×750 | 500×750 | 425 | 50-100 | 40-110 | 275 | 55 |

| PE-600×750 | 600×750 | 500 | 150-200 | 80-240 | 275 | 55 |

| PE-600×900 | 600×900 | 500 | 65-160 | 50-180 | 250 | 55 |

| PE-750×1060 | 750×1060 | 630 | 80-140 | 110-320 | 250 | 110 |

| PE-800×1060 | 800×1060 | 640 | 130-190 | 130-330 | 250 | 110 |

| PE-830×1060 | 830×1060 | 650 | 160-220 | 150-336 | 250 | 110 |

| PE-870×1060 | 870×1060 | 660 | 200-260 | 190-336 | 250 | 110 |

| PE-900×1060 | 900×1060 | 685 | 230-290 | 230-390 | 250 | 110 |

| PE-900×1200 | 900×1200 | 750 | 95-165 | 220-450 | 200 | 110 |

| PE-1000×1200 | 1000×1200 | 850 | 195-265 | 315-500 | 200 | 110 |

| PE-1200×1500 | 1200×1500 | 1020 | 150-350 | 400-800 | 180 | 160-220 |

| PE-1500×1800 | 1500×1800 | 1200 | 220-350 | 500-1000 | 180 | 280-355 |

| PE-1600×2100 | 1600×2100 | 1500 | 300-400 | 1300-2200 | 160 | 350-380 |

| PEX-150×750 | 150×750 | 120 | 18-48 | 8-25 | 320 | 15 |

| PEX-250×750 | 250×750 | 210 | 25-60 | 13-35 | 330 | 30 |

| PEX-250×1000 | 250×1000 | 210 | 25-60 | 16-52 | 330 | 30 |

| PEX-250×1200 | 250×1200 | 210 | 25-60 | 20-61 | 330 | 37 |

| PEX-300×1300 | 300×1300 | 250 | 20-90 | 16-105 | 300 | 55 |