Popular searched products:

Product Description

The heavy hammer crusher is improved on the basis of the small hammer crusher. It does not have grate plates, so it discharges materials very quickly. It has a large output and high crushing efficiency. It uses direct impact of the hammer head to break the stone, so Its crushing efficiency is higher than that of the squeeze crusher.

PCZ heavy-duty hammer crusher is also called heavy hammer crusher. During the operation of the equipment, the high-speed hammer body collides with the material to crush the material. It has the characteristics of simple structure, one-time molding, large crushing ratio, small product particle size, and high production efficiency. , can be used for dry and wet crushing, and is suitable for fine crushing of medium hardness and brittle materials in mining, cement, coal, building materials, combustion and other departments. The large hammer crusher can adjust the gap between the hammer head and the liner according to user requirements, and change the discharge particle size to meet the different crushing needs of different users.

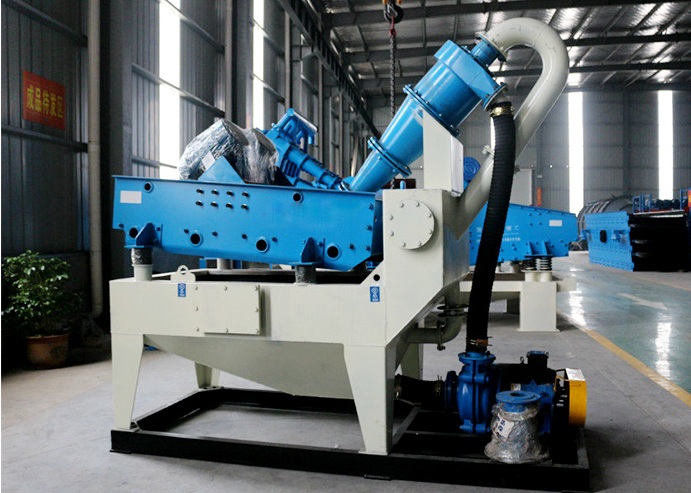

Real shot of heavy hammer crusher

Product Performance

- 1Large crushing ratio and good finished product particle size

The incoming material has large particle size and the discharging particle size is small. The finished material can be adjusted to coarse or medium as required. , fine and other specifications, no flakes, no smooth bodies, multi-angles and edges to ensure compressive strength.

- 2Low operating cost and low investment

The heavy-duty hammer crusher has one-time molding, without the need for secondary crushing and shaping process, completely achieving one-stop crushing Two-break low-cost operation can reduce costs by about 40%.

- 3Long service life

The hammer head of the heavy hammer crusher can rotate 360°, which increases the elasticity of the hammer head and allows the hammer handle to encounter large pieces Materials or materials with slightly higher hardness are not easy to break when impacted, which increases the service life of the hammer head.

- 4Energy saving, environmental protection, and pollution reduction

The hammer crusher can be used for dry and wet crushing. When crushing wet materials, water can be added to reduce dust. causing pollution to the environment.

Working Principle

The hammer crusher uses impact to crush materials. The main working component is the rotor with a hammer head. The rotor consists of a main shaft, a disc, a pin and a hammer head. The motor drives the rotor to rotate at high speed in the crushing cavity. The material enters the machine from the upper feeding port and is crushed by the blow, impact and grinding of the high-speed hammer head. There is a sieve plate at the lower part of the rotor. The particles smaller than the screen hole size in the crushed materials are discharged through the sieve plate. The coarse particles larger than the screen hole size are retained on the sieve plate and continue to be hit and ground by the hammer head. plate discharge.

Technical Parameters

| Model | Specifications | Feeding port size (mm) | Maximum feed particle size (mm) | Production capacity (t/h) | Motor power (kw) | Outline dimensions (mm) |

| PCZ1310 | 1310X1050 | 890X1075 | ≤650 | 150-180 | 160 | 2950X2250X2495 |

| PCZ1512 | 1500X1160 | 1200X900 | ≤600 | 250-400 | (160kw-4)*2 | 3220X2520X2800 |

| PCZ1615 | 1675X1510 | 1480X1200 | ≤650 | 400-800 | (220kw-4)*2 | 3665X2915X3440 |

| PCZ1620 | 1660X1900 | 2000X1200 | ≤800 | 800-1000 | 400KW*2 | 3500X3100X3200 |

| PCZ1820 | 1800X1964 | 2000X1200 | ≤800 | 800-1500 | 800KW-6 | 3474X3822X3520 |

| PCZ2020 | 1920X2000 | 2010X1200 | ≤800 | 1200-1600 | 800KW-6 | 4160X3920X3520 |

| PCZ2125 | 2100X2486 | 2600X1690 | ≤1200 | 2000-3000 | 1250KW-6 | 5057X4565X4666 |

| PCZ3032 | 3000X3220 | 3240X1840 | ≤1200 | 4500-6000 | (1250KW-6)*2 | 6710X6122X6340 |