Cement production line with daily output of 1,500 tons

Production Capacity:1500T/d

Processing materials:limestone and clay

Power Consumption:≤110kwh/t cement

Production Capacity:1500T/d

Processing materials:limestone and clay

Power Consumption:≤110kwh/t cement

Global Heavy industry quality is good

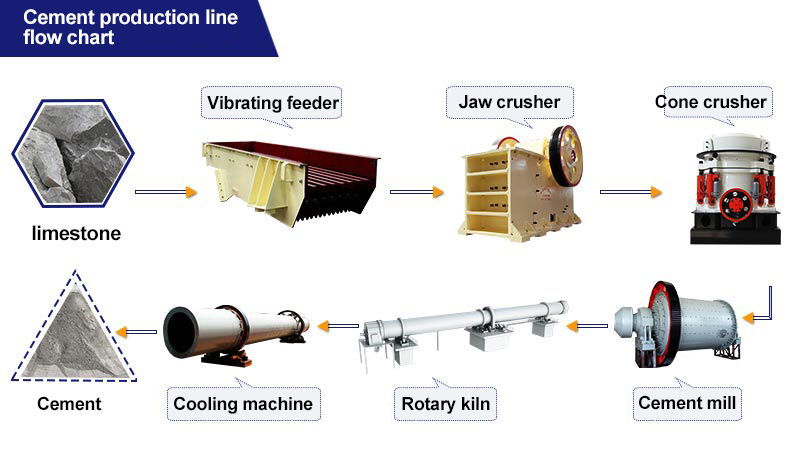

Mechanical equipment includes limestone crushing and transportation, clay crushing, raw coal crushing, raw coal and auxiliary raw material pre-homogenization yard, raw material batching station, raw material grinding and waste gas treatment, raw material homogenization warehouse and raw material entering the kiln. The end of the firing kiln, the middle and tertiary air ducts of the firing kiln, the head of the firing kiln, clinker transportation, clinker storage and transportation, pulverized coal preparation and metering transportation, cement batching station and clinker bulk, gypsum, mixed material crushing and Conveying, cement grinding and conveying, cement storage and conveying, cement packaging, bagged cement loading, cement truck bulk packaging, machine repair workshop and total material warehouse, etc.

1. High output and low energy consumption: high output, low consumption and good energy saving effect during operation.

2. Low pollution: The sealing system and dust removal system of the entire cement production line are well made, so the dust emissions during the production process are small.

3. High energy conversion rate: Electric energy and heat energy in the production process are fully utilized, and the conversion rate is high.

1) Crushing and pre-homogenization.

Use a crusher to crush cement production raw materials such as limestone, clay, iron ore and coal, and use science and technology to preliminarily homogenize the raw materials during the storage and retrieval process.

2) Raw meal preparation.

Reasonable selection of grinding equipment and process flow, optimization of process parameters, correct operation, and control of operating systems are of great significance to ensuring product quality and reducing energy consumption.

3) Homogenization of raw materials.

In the production process of new dry process cement, stabilizing the composition of the raw meal entering the pit is the prerequisite for stabilizing the thermal system of clinker firing. The raw meal homogenization system plays a check role in stabilizing the composition of the raw meal entering the pit.

4) Preheating and decomposition.

Mainly including material dispersion, gas-solid separation, pre-decomposition and other steps.

5) Firing of cement clinker.

In the rotary kiln, the carbonate further rapidly decomposes and undergoes a series of solid phase reactions to generate minerals in cement clinker.

6) Cement grinding.

It is a process in the cement production process and also a process that consumes a lot of electricity. Its main function is to grind cement clinker to a suitable particle size to form a certain particle gradation, increase its hydration area, accelerate the hydration rate, and meet the requirements for cement slurry coagulation and hardening.

7) Cement packaging.