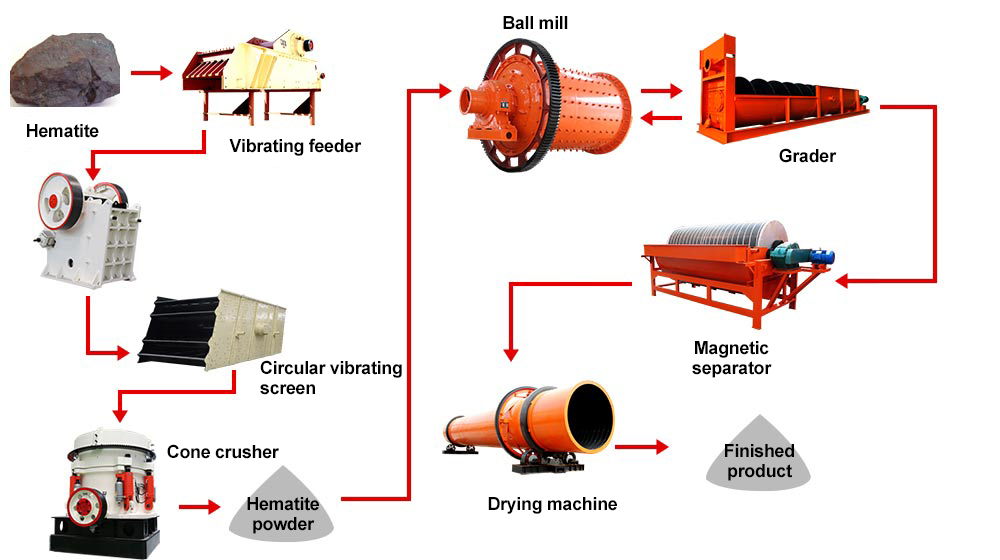

iron ore beneficiation production line

Production Capacity:4-25t/h

Processing materials:iron ore

Power Consumption:No data

Production Capacity:4-25t/h

Processing materials:iron ore

Power Consumption:No data

Global Heavy industry quality is good

Project Overview: The Shanxi 200t/d iron ore dressing plant project is a full mining industry chain undertaken by Global Heavy Industry, including ore dressing testing, mine design, equipment manufacturing and shipping, installation and commissioning, worker training, dressing plant management and operation. Service (EPC+M+O) project.

1. Small equipment wear: Because a cone crusher is used in the second crushing, the cone crusher's own protection device will discharge materials with excessive hardness from the entire production line, thus ensuring the normal operation of subsequent equipment and reducing their wear. quantity;

2. Stable operation: The entire production line is designed as a set, so each piece of equipment can deliver its best performance, ensuring the output of the production line and producing little noise and dust pollution;

3. Good product quality: Different magnetic separators are used to magnetically separate iron powder, which increases the content of iron powder in the product.

The mined ore is initially crushed by the main jaw crusher in the mineral processing equipment. After being crushed to a reasonable fineness, it is evenly sent to the ball mill through the elevator and feeder. The ore is crushed and ground by the ball mill of the mineral processing equipment. . The fine ore ground by the ball mill enters the next process: classification. The spiral classifier uses the principle that the specific gravity of solid particles is different and the speed of precipitation in the liquid is different to clean and classify the ore mixture. The classified mineral particles are sent to the flotation machine, and different drugs are added according to different mineral properties to separate the desired minerals from other substances. After the desired minerals are separated, because they contain a large amount of water, they must be initially concentrated by a concentrator and then dried by a dryer to obtain dry minerals.

After beneficiation, the grade of iron concentrate has reached more than 64%, the SiO2 content is generally controlled below 6%, and the content of toxic elements such as S and P has reached the standards set by the country and steel companies. We are very happy with this production line!