400t/h kaolin mineral processing production line

Production Capacity:400t/h

Processing materials:Kaolin clay

Power Consumption:No data

Production Capacity:400t/h

Processing materials:Kaolin clay

Power Consumption:No data

Global Heavy industry quality is good

Kaolin is an aluminum-containing silicate mineral that is white and ooze-like, has low viscosity, low plasticity, and has good insulation and chemical stability. Kaolin contains clay minerals and non-clay minerals. The common clay minerals are kaolinite, halloysite, montmorillonite and hydromica; the non-clay minerals are mainly quartz, feldspar, mica, heavy minerals and a small amount of authigenic secondary minerals. There are certain differences in the properties of kaolin clay from different regions.

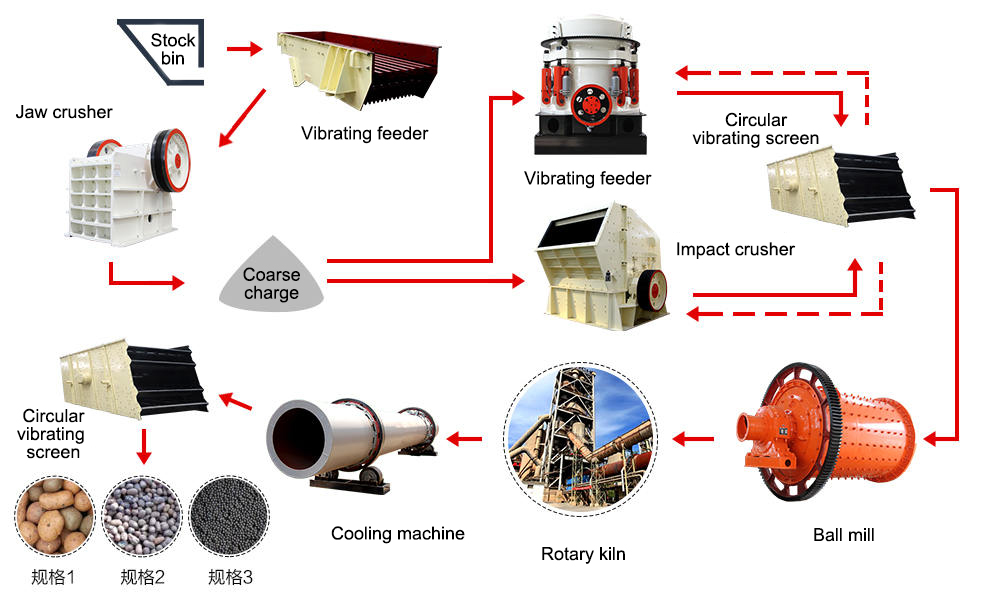

1. The production line is reasonably designed, ranging from coarse crushing, grinding to flotation, and the finished product is of good quality;

2. It complies with environmental protection requirements and standards, has advanced technology and can meet customers’ production requirements;

3. The operating cost is low, the energy saving and environmental protection effect is good, and the subsequent profit creation is high;

Generally, kaolin processing can be divided into wet and dry methods. Since the kaolin processed by this customer is coal-based kaolin, the main flow of the entire kaolin processing production line designed for the customer is raw ore → crushing → slurry → Cyclone classification → peeling → centrifugal classification → concentration → filter press → internal steam drying → calcination → depolymerization, etc. In the calcination process, the crushed kaolin is stored in the silo, lifted by the elevator and transported to the preheater Top silo. Then it is evenly distributed into each chamber of the preheater through the discharge pipe. In the preheater, it is heated and decomposed by the kiln flue gas, and is pushed into the rotary kiln through the hydraulic push rod. The kaolin is sintered and decomposed in the rotary kiln, and then cooled after decomposition. The cooler is cooled and discharged by the cold air blown into the cooler. The calcination process is the key process and is also related to the purity and whiteness of the finished kaolin.

The flotation machine provided by Global Heavy Industry is fully matched with the crusher, ball mill and other equipment, and has achieved better kaolin Xuna mining results. Nearby companies have praised this production line as convenient, easy to use, economical and affordable.