Popular searched products:

Product Description

The structure of the roller screen

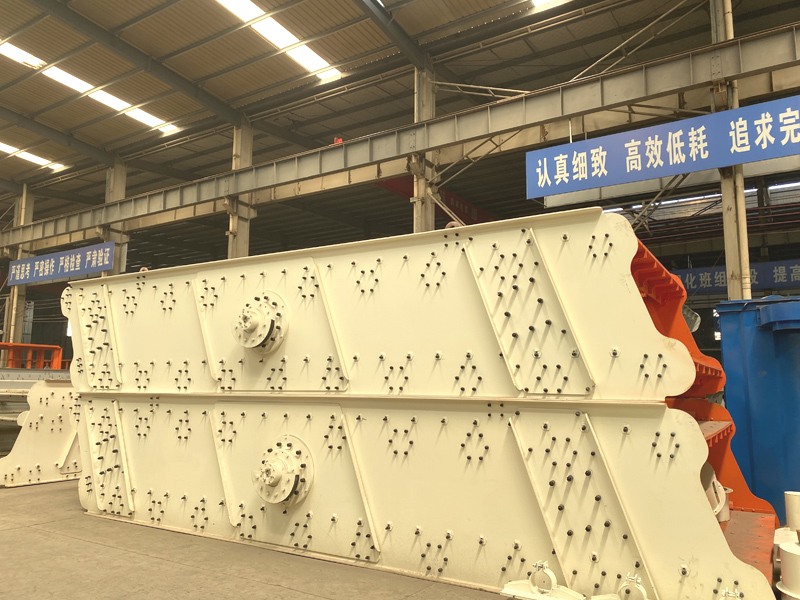

The new roller screen is basically composed of the transmission mechanism and the screen machine itself. The transmission mechanism consists of motor, coupling, reducer and bevel gear reducer. Bevel gear reducers include multi-stage vertical shafts and gear shafts. Due to the good sealing and lubrication conditions of the sealing box, the transmission mechanism operates reliably.

The screening machine itself consists of screen frame, screen shaft and screen plate. There are several wear-resistant screen plates on each screen shaft, and the screen plates near the two screen shafts are staggered to create a rolling screen surface. The screen plate is installed on the screen shaft and is a steel casting. The main shapes are plum blossom shape and finger shape. If the wear is severe, it can be replaced separately. One of the screen shafts is equipped with a gear shaft, which meshes with a bevel gear on a transmission-driven multi-stage body shaft.

Product Performance

- 1 High screening efficiency

The excitation force can be adjusted, the flow rate can be changed and controlled at any time, and the adjustment is convenient and stable; multi-layer screening, each specification The screening is clear and the screening efficiency is high.

- 2High screening precision

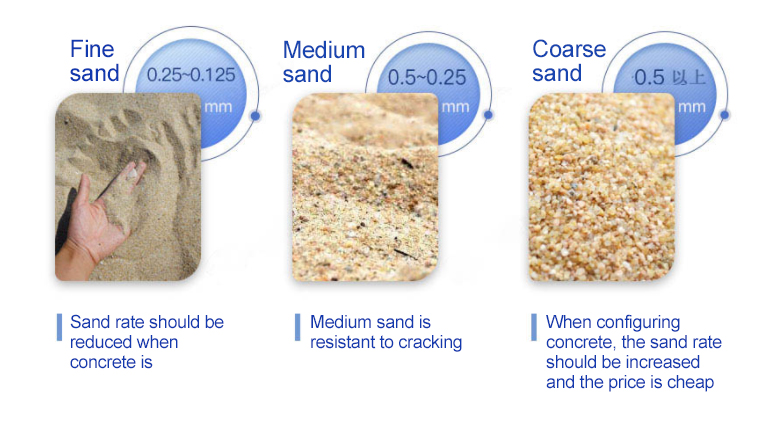

The mesh size of the roller screen can be adjusted as needed, which can achieve very high screening precision and ensure the product quality. quality.

- 3High degree of automation

The roller screen can realize automated operation and reduce labor input and production costs.

Working Principle

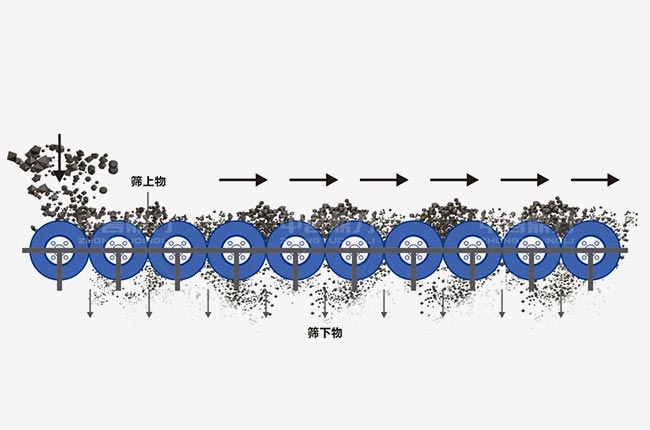

The screen surface of the roller screen is composed of multiple screen shafts arranged in parallel and equipped with screen sheets. The screen shaft is driven to rotate through a transmission device, and its rotation direction is the same as the material flow direction. The gap between the screen shaft and the screen plate forms a screen hole. Materials smaller than the screen hole are affected by the weight of the screen shaft and the rotational force of the screen shaft. They pass through the screen hole and become under the screen. Materials larger than the screen hole continue to move forward along the screen surface. The movement becomes the upper material on the screen, and finally the classification of materials is achieved. In order to prevent materials from jamming the screen shaft, it is equipped with electrical and mechanical overload protection functions. The screening particle size needs to be adjusted according to the user's requirements, the screen shaft gap and the size of the screen pieces.

Technical Parameters

| Model | Trough length × width (mm) | Screening area (㎡) | Feeding particle size (mm) | Processing capacity (t/d) | Motor (kw-4) |

| DLGS2610 | 3600×2600 | 9.36 | <1000 | 1500-1900 | 55×2 |

| DLGS2410 | 3600×2400 | 8.64 | <1000 | 1000-1500 | 45×2 |

| DLGS1810 | 3600×1800 | <800 | 500-900 | 37 ×5 |