Popular searched products:

Product Description

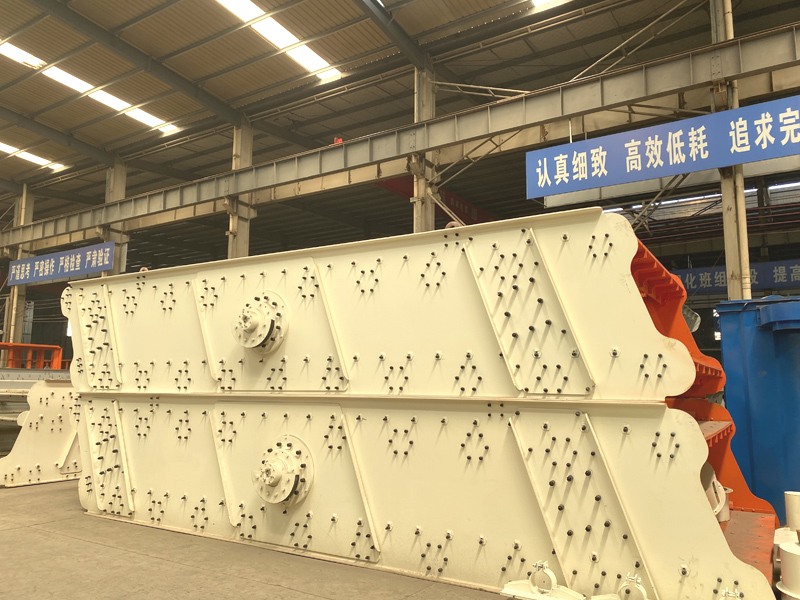

The circular vibrating screen machine mainly consists of a screen box, a screen mesh, a vibrator, a damping spring device, a chassis, and a motor. A cylinder-type eccentric shaft vibrator and an eccentric block are used to adjust the amplitude. The vibrator is installed on the side plate of the screen box, and is driven by a motor to rotate through a triangle belt, which generates centrifugal inertia force and forces the screen box to vibrate. The side plates of the vibrating screen are made of high-quality steel plates, and the side plates, cross beams and exciter base are connected with high-strength bolts or ring-groove rivets. The vibrator is installed on the side plate of the screen box, and is driven to rotate by the motor through the coupling, which generates centrifugal inertial force, forcing the vibrating screen to vibrate and screen the sand and gravel.

Product Performance

- 1Easy to adjust, high screening efficiency

The excitation force can be adjusted, and the flow rate can be changed and controlled at any time. The adjustment is convenient and stable; multi-layer screening, Each grade of specifications is screened clearly and the screening efficiency is high.

- 2Reliable operation and low failure rate

The structure adopts a cylinder-type vibrator and offset block adjustment device, and an advanced rivet-connected assembled frame structure The service life of the equipment is increased, and the spring damping device reduces the impact on the foundation. Under normal use, the probability of sudden failure during work is small.

- 3Unique design, anti-clogging

Parts in direct contact with materials are all made of stainless steel, which is easy to clean. The screen design is exquisite, durable and efficient. , The mesh is not blocked and there is no flying powder.

- 4Low noise, small crushing pollution

Using rubber vibration isolation spring, it has long service life, low noise and smooth resonance zone. The fuselage adopts a closed structure, which can effectively prevent dust pollution.

Working Principle

When the YZK series circular vibrating screen is working, the motor causes the eccentric block of the vibrator to rotate at high speed through the triangle belt. The running eccentric block generates a large centrifugal force, which stimulates the screen box to produce a circular motion of a certain amplitude. The material on the screen is subjected to the impulse transmitted by the screen box on the inclined screen surface and produces a continuous throwing motion. The process of the encounter between the material and the screen surface. The particles smaller than the sieve hole are allowed to pass through the sieve to achieve classification.

Technical Parameters

| Model | Screen surface specifications W×L(mm) |

Number of screen layers | Feeding size (mm) | Mesh size (mm) | Production capacity (t/h) | Power (kw) | Vibration frequency (r/min) | Double amplitude (mm) |

| 2YZK1237 | 3700×1200 | 2 | ≤400 | 3-50 | 30-100 | 5.5 | 970 | 5-9 |

| 3YZK1237 | 3700×1200 | 3 | ≤400 | 3-50 | 30-100 | 7.5 | 970 | 5-9 |

| 2YZK1548 | 4800×1500 | 2 | ≤400 | 3-100 | 30-275 | 15 | 970 | 5-9 |

| 3YZK1548 | 4800×1500 | 3 | ≤400 | 3-100 | 30-275 | 15 | 970 | 5-9 |

| 2YZK1848 | 4800×1800 | 2 | ≤400 | 3-100 | 56-330 | 18.5 | 970 | 5-9 |

| 3YZK1848 | 4800×1800 | 3 | ≤400 | 3-100 | 56-330 | 18.5 | 970 | 5-9 |

| 4YZK1848 | 4800×1800 | 4 | ≤400 | 3-80 | 56-330 | 22 | 970 | 5-9 |

| 2YZK1860 | 6000×1800 | 2 | ≤400 | 3-100 | 65-586 | 18.5 | 970 | 5-9 |

| 3YZK1860 | 6000×1800 | 3 | ≤400 | 3-100 | 65-586 | 22 | 970 | 5-9 |

| 4YZK1860 | 6000×1800 | 4 | ≤400 | 3-100 | 65-586 | 30 | 980 | 5-9 |

| 2YZK2160 | 6000×2100 | 2 | ≤400 | 3-100 | 81-720 | 22 | 980 | 5-9 |

| 3YZK2160 | 6000×2100 | 3 | ≤400 | 3-100 | 81-720 | 30 | 970 | 5-9 |

| 4YZK2160 | 6000×2100 | 4 | ≤400 | 3-100 | 81-720 | 30 | 980 | 5-9 |

| 2YZK2460 | 6000×2400 | 2 | ≤400 | 3-150 | 100-810 | 22 | 970 | 5-9 |

| 3YZK2460 | 6000×2400 | 3 | ≤400 | 3-150 | 100-810 | 30 | 980 | 5-9 |

| 4YZK2460 | 6000×2400 | 4 | ≤400 | 3-150 | 150-850 | 37 | 980 | 5-9 |

| 2YZK2870 | 7000X2800 | 2 | ≤400 | 5-100 | 120-680 | 22x2 | 750 | 8 |

| 3YZK2870 | 7000X2800 | 3 | ≤400 | 5-100 | 180-720 | 22x2 | 750 | 8 |

| 2YZK3070 | 7000X3000 | 2 | ≤400 | 5-100 | 200-700 | 37 | 750 | 8 |

| 3YZK3070 | 7000X3000 | 3 | ≤400 | 5-100 | 230-800 | 45 | 750 | 8 |