Popular searched products:

Sand is an important building material today. Many users are confused about how to distinguish fine sand, medium sand, coarse sand, etc., and they do not know much about what kind of sand making equipment and machine prices are needed to turn coarse sand into fine sand. This article will introduce it to you in detail.

How to distinguish between fine sand, medium sand and coarse sand

Distinguish by thickness

The thickness of sand refers to the average thickness of sand particles of different particle sizes mixed together, which can be divided into fine sand, medium sand and coarse sand. The particle gradation of sand refers to the proportion of large and small particles in the sand. The porosity of sand depends on the matching degree of sand particle size. Well-graded sand not only saves cement, but also improves the compactness and strength of concrete and mortar.

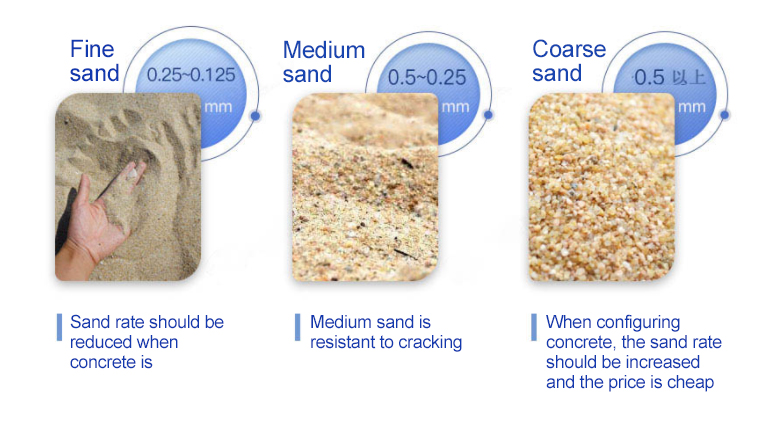

1. Fine sand: sand with a fineness modulus of 2.2~1.6, particles with a particle size greater than 0.075mm accounting for more than 85% of the total weight, and an average particle size of 0.25mm~0.125mm.

2. Medium sand: sand with a fineness modulus of 3.0~2.3, a particle size greater than 0.25mm exceeding 50% of the total weight, and an average particle size of 0.5~0.25mm.

3. Coarse sand: sand with a fineness modulus of 3.7~3.1, a particle content greater than 0.5mm and accounting for more than 50% of the total weight, and an average particle size of 1mm~0.5mm.

Distinguished by scope of use

1. The difference between medium sand and fine sand is not very big. Mortar for building walls and plastering can be used in many places.

2. Coarse sand is generally cheaper. In order to save costs, many people use coarse sand instead of other sand. However, coarse sand contains heavier mud and is more suitable for mortar floors.

3. In general construction, fine sand is rarely used alone and is only used in mortar. Other times, more coarse sand is used, mainly to resist cracking.

4. When preparing concrete, medium sand should be preferred. When using coarse sand, the sand rate should be increased and sufficient cement dosage should be maintained; when using fine sand, the sand rate should be appropriately reduced.

Fine sand treatment uses equipment such as sand making machines, sand washing machines, and fine sand recovery machines. In addition, the discharge granularity is flexibly adjustable and can produce fine sand that meets user needs. In addition, it has many advantages, such as:

Environmental protection: The fine sand recovery machine is a new type of environmentally friendly sand making equipment. The air flow in the cavity can form self-circulation, which is less likely to produce dust and noise.

High output: The fine sand recovery machine has strong sand recovery capabilities. The finished fine sand particles processed by the fine sand recovery machine are also in good shape, with reasonable gradation and adjustable fineness. Very suitable for artificial sand making and stone modeling.

Related Reading

- What is the production cost of fine sand recycling machine? What are the key factors that affect the price of fine sand recovery machines?

- Where can I buy a fine sand recycling machine that is reliable? Which manufacturers sell fine sand recycling machines cheaply?

- Regarding the price of mobile sand making machines, manufacturer recommendations, and sand blasting effects, this article has everything you want to know!

- What is machine-made sand? Why is machine-made sand so popular? What are the advantages of machine-made sand?

Product show

Product

Source:

Source: Time:2024/05/09 16:28:57

Time:2024/05/09 16:28:57