Popular searched products:

Product Description

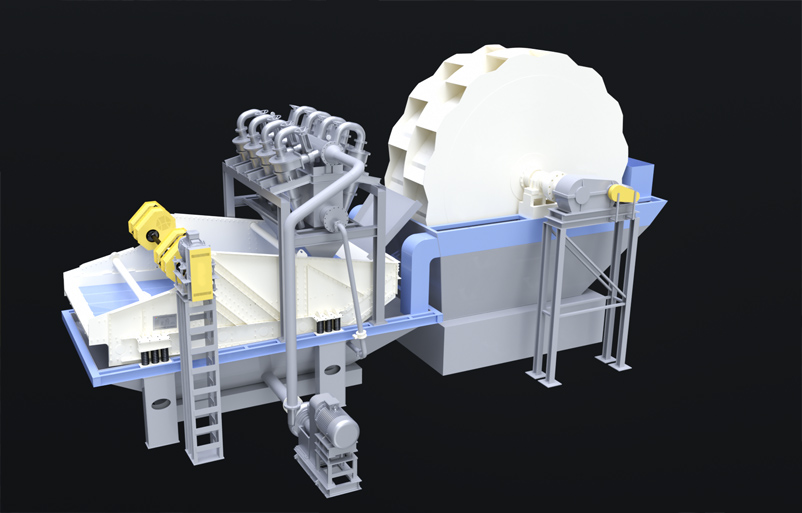

The integrated fine sand recovery machine, referred to as the fine sand recovery machine, is a fine sand recovery device that uses a slurry pump to inject mud with a concentration of less than 40% into a hydraulic rotary separator for separation. According to different structures, this equipment can be divided into wheel-type sand washing and recycling integrated machine and spiral sand washing and recycling integrated machine. No matter what kind of recycling equipment, it can be used in the recycling of artificial sand, machine-made sand production line, and coal preparation plant coarse slime. Wait for it to exert great value and complete the recycling operation.

Product Performance

- 1Less loss of fine sand and high cleanliness of the finished product.

The integrated recycling machine combines sand washing, fine sand recovery, dehydration and other technologies. It occupies a small area, has high cleanliness of the finished product, less fine sand loss, and large processing capacity.

- 2Long service life.

The wearing parts are made of materials with good wear resistance, which has a long replacement cycle and a long service life of the whole machine.

- 3Low investment cost.

The fine particles are fully recovered, which reduces the workload of the sedimentation tank and reduces the cleaning cost of the sedimentation tank.

- 4There are many choices

There are many types and models of fine sand recovery machines, and users can make reasonable purchases based on actual production needs.

Working Principle

The pre-processed materials are sent to the cleaning box, separated by the rotary separator, and then enter the dehydration screen. After dehydration through the dehydration screen, the fine sand and water are effectively separated, and a small amount of fine sand, mud, etc. are returned to the return box. The cleaning tank realizes the recycling of fine sand and the reuse of water resources, and has good energy saving effect. When the soil content in the cleaning tank is too high, add the sediment mixture and water into the cleaning tank to raise the liquid level, and finally discharge it from the water outlet.

Technical Parameters

| Model | Separator specifications (mm) | Dewatering screen power (kw) | Water pump motor power (kw) | Vibration motor power (kw) | Screen surface size (mm) | Production capacity (t/h) |

| BX250 | 250 | 2x0.55 | 11-17.5 | 2x 0.55 | 700x1800 | 30-80 |

| BX300 | 300 | 2x0.75 | 11-15 | 2x 0.75 | 900x2000 | 40-100 |

| BX350 | 350 | 2x0.75 | 15 | 2x 0.75 | 900x2000 | 70-130 |

| BX550 | 550 | 2x1.1 | 15-22 | 2x 1.1 | 1500x3000 | 100-220 |

| BX650 | 650 | 2x1.1 | 18.5-30 | 2x 1.1 | 1500x3000 | 120-272 |

| BX750 | 750 | 2x1.5 | 37-55 | 2x 1.5 | 1500x3000 1800x4000 |

180-350 |

| BX900 | 900 | 2x2.2 | 55-65 | 2x 2.2 | 1800x4000 2000x5000 |

250-500 |