Popular searched products:

Product Description

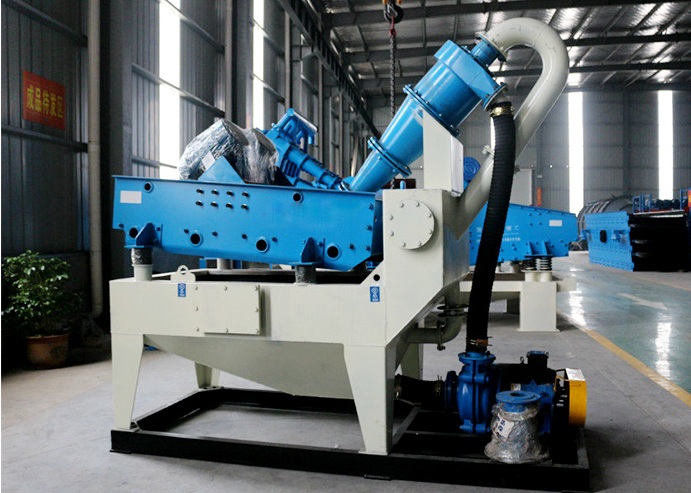

The fine crusher has a wide range of uses and high crushing efficiency. Its performance has reached the advanced level. It is currently the most effective, practical and reliable stone crushing machine. It is an energy-saving gravel and sand making equipment. It is more energy-saving than the traditional fine crusher and can be widely used. Materials with different properties, such as granite, quartz sand, steel sand, slag powder, copper ore, quartz stone, iron ore, bauxite, steel sand, etc.

The fine crusher has stable and reliable operation, simple structure, easy maintenance, strong production capacity and long service life. The investment cost of the fine crusher is 35%-50% lower than the traditional process equipment of the same scale, the output efficiency is 35%-50% higher than the traditional process equipment of the same scale, and the operating cost is also 35%-50% lower than the traditional process equipment of the same scale. It is widely used in machine-made sand and gravel, high-grade highways, railways, water conservancy, airports, construction, cement, metallurgy and other industries to produce high-quality stones.

Product Performance

- 1Reliable and safe performance

The fine crusher has stable and reliable operating performance, simplified process, simple structure and easy maintenance. The production capacity is large and the hammer head has a long service life.

- 2Low maintenance costs

According to statistics, long-term operation and maintenance costs are also lower than traditional process equipment of the same scale.

- 3Can work continuously

When the fine crusher is working, it can work continuously. When working, driven by the motor, the rotor rotates at high speed and the material enters the crushing chamber. Broken, thereby achieving the crushing work.

- 4Special design

The overall design is beautiful in appearance, compact in structure, small in weight and low in power consumption per unit product.

- 5High operating rate, uniform product

High fine crushing efficiency, extremely low power consumption, good dust protection, high operating rate, and the production of materials at the same time Large unevenness, good grain shape.

- 6Long life of the hammer head

The hammer head of the fine crusher is made of high-quality wear-resistant alloy steel material and adopts advanced casting, forging and heat treatment processes. This greatly extends component life.

Working Principle

The main working part of PC hammer crusher is the rotor with hammer head. During operation, the motor drives the rotor to rotate at high speed in the crushing cavity. The material is fed into the crushing cavity of the hammer crusher from the upper feeding port. The material is crushed due to the impact, shearing and tearing of the high-speed rotating hammer head. There is a sieve plate at the lower part of the rotor. The crushed materials with particle sizes smaller than the screen hole size are discharged through the sieve plate. The coarse particles larger than the screen hole size are blocked on the sieve plate and continue to be impacted and ground by the hammer until they are crushed. After the particle size is required, it is discharged through the sieve plate.

Technical Parameters

| Model | Feeding particle size (mm) | Discharge particle size (mm) | Production capacity (t/h) | Power (kw) | Weight(t) | Outline dimensions (mm) |

| PCФ400×300 | ≤200 | ≤25 | 5-10 | 11 | 0.8 | 900 × 670 × 860 |

| PCФ600×400 | ≤250 | ≤30 | 10-22 | 22 | 2.26 | 1200 × 1050 × 1200 |

| PCФ800×600 | ≤250 | ≤35 | 18-40 | 55 | 4.8 | 1310 × 1180 × 1310 |

| PCФ1000×800 | ≤350 | ≤35 | 25-50 | 75 | 5.9 | 1600 × 1390 × 1575 |

| PCФ1000×1000 | ≤500 | ≤35 | 30-80 | 90 | 8 | 1800 × 1590 × 1775 |