Popular searched products:

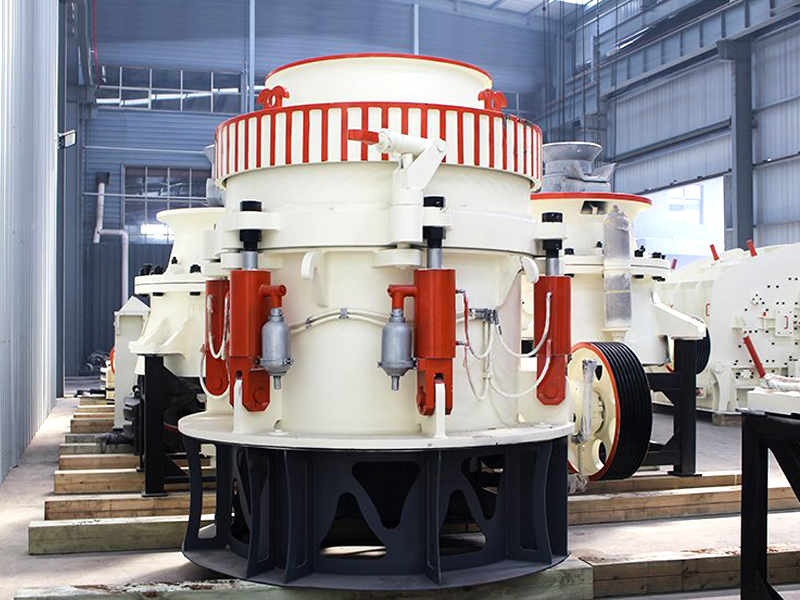

What is the reason for oil leakage in cone crusher?

Oil leakage from the cone crusher is one of the common faults. There are four main reasons for this: failure of the sealing device; blockage of the oil return pipeline; improper working pressure; unreasonable component clearance. The preventive measures are as follows.

1—Ensure the equipment is well sealed:

Reasonably design and process the sealing structure to ensure good sealing performance of the sealing device.

Install the sealing ring correctly to ensure that the equipment is well sealed. Do not use angular tools to install the sealing ring to prevent scratching the sealing ring.

2—Inspection during production:

Regularly check whether the filter is clogged or damaged, and replace the kinked oil drain line to ensure the smoothness of the oil return line.

Check whether the gap between the inner wall of the oil pool on the main base and the oil retaining ring on the counterweight body is reasonable to prevent the lubricating oil from splashing into each other to form an oil seal, thereby causing oil leakage in the cone crusher.

3—Prohibit lubricating oil temperature from rising

The increase in lubricating oil temperature will easily reduce the viscosity of the oil and accelerate the aging of sealing components, thus causing serious oil leakage.

Note: As the lubricating oil temperature rises, the heat dissipation area and heat dissipation effect of the oil tank can be increased. If necessary, a cooler can be added to reduce the lubricating oil temperature.

Source:

Source: Time:2024/04/24 10:27:29

Time:2024/04/24 10:27:29