Popular searched products:

Product Description

Rod mill is a kind of equipment used for processing metal materials. It can process rough metal rods into rods with smooth surfaces and standard sizes. This equipment is widely used in metallurgy, mechanical processing, construction, automobile and other industries, and is an indispensable part of modern industrial manufacturing process.

The mill is mainly composed of motor, main reducer, transmission part, cylinder part, main bearing, slow transmission part, feed part, discharge part, annular seal, thin oil lubrication station, large and small gear injection lubrication, foundation part, etc. The main reducer is parallel shaft and hard tooth surface. Rod mill is an asynchronous motor connected with a small gear through a reducer, directly driving the surrounding large gear to reduce the rotation and drive the rotating part to rotate. The cylinder is equipped with appropriate grinding media-steel rods. Under the action of centrifugal force and friction, the grinding media continuously enters the cylinder from the feeding part, is crushed by the moving grinding media, and the product is discharged out of the machine through overflow and continuous feeding force for the next process.

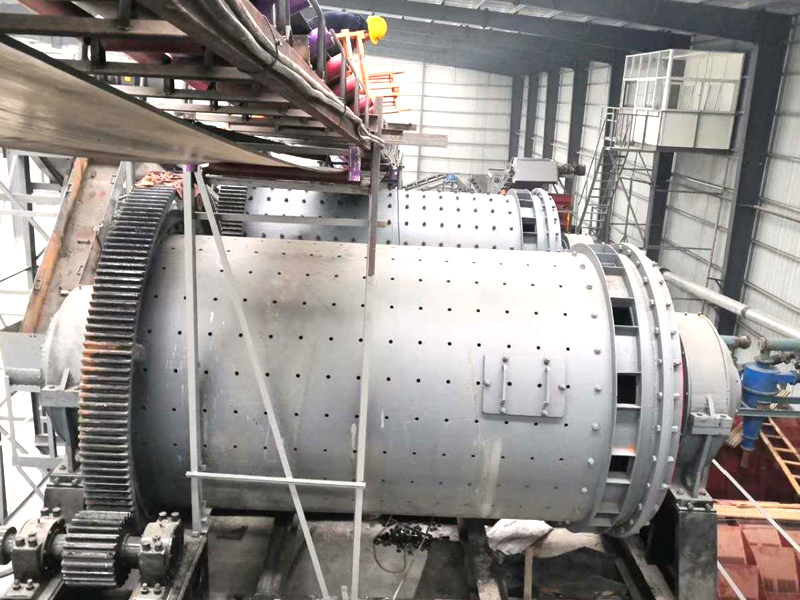

Real shot display

Product Performance

- 1Save power

Save more than 40% of power compared to the old equipment. The product particle size is more uniform, with less coarse particles and ore mud. Compared with the particle size characteristics of the rod mill product and the ball mill product, the particle size characteristic curve of the rod mill working in an open circuit is almost the same as that of the ball mill working in a closed circuit.

- 2Uniform discharge and high output

Adopting advanced controllable feeding and discharging rod mill technology, combined with the actual user's grinding materials, suitable grinding bodies are used, and the surface contact of the traditional ball mill is changed to line contact, so that the Zhongjia energy-saving rod mill has uniform discharge particle size and high output, which is suitable for ores of different hardness (Mohs hardness 5.5~12).

- 3 Feed particle size tolerance

The crushing ratio of the rod mill is 15:1 to 20:1. The conventional crushing and grinding process of most foreign beneficiation plants is composed of a crusher, a rod mill, and a ball mill. Few of my country's beneficiation plants use rod mills. The feed particle size of the ball mill is relatively high, resulting in high energy consumption, grinding medium consumption, and liner consumption. Since the rods of the rod mill are in line contact, large materials are ground first, and it has a selective grinding effect. Therefore, the product particle size range is narrow, the product particle size is uniform, the over-crushing phenomenon is less, and the grinding efficiency is higher.

Working Principle

When the rod mill is running, the steel bars in the cylinder are in line contact, and the larger particles are crushed first. When the steel bars are driven upward, the coarse particles are often clamped between the bars, while the fine particles are easy to leak through the gaps of the bars with the slurry. Therefore, there is a kind of "screening and grading" effect between the bars, which makes the equipment have a strong "selective grinding" characteristic.

Technical Parameters

| Model Specifications | Diameter (mm) | Length (mm) | Drum Speed (r/min) | Feeding Particle Size (mm) | Discharging Particle Size (mm) | Output (t) | Power (kw) | Rod Loading Quantity |

| GMB1835 | φ1800 | 3500 | 22.8 | ≤25 | ≤5 | 20-50 | 160 | 13 |

| GMB2136 | φ2100 | 3600 | 20.9 | ≤25 | ≤5 | 30-70 | 210 | 18 |

| GMB2145 | φ2100 | 4500 | 20.9 | ≤25 | ≤5 | 50-80 | 250 | 20 |

| GMB2436 | φ2400 | 3600 | 19 | <20 | ≤5 | 60-120 | 280 | 21 |

| GMB2736 | φ2700 | 3600 | 17.5 | <20 | ≤5 | 100-220 | 400 | 24 |

| GMB2745 | φ2700 | 4500 | 17.5 | <20 | ≤5 | 120-250 | 500 | 27 |

| GMB3245 | φ3200 | 4500 | 16 | <20 | ≤5 | 300-450 | 800 | 50 |

| GMB3645 | φ3600 | 4500 | 15 | <20 | ≤5 | 430-580 | 1000 | 55 |