Popular searched products:

Product Description

The ball mill is a key equipment for crushing materials after they are crushed. It is suitable for crushing various ores, gold, silver, copper, iron, various metal beneficiation, cement, fertilizer, silicate products, refractory materials, glass and other materials.

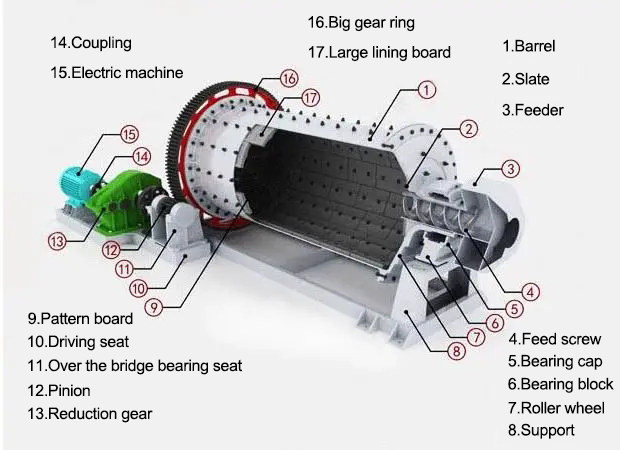

The ball mill is composed of the main parts such as the cylinder, stone plate, feeder, feed screw, bearing cover, bearing seat, roller, bracket, flower plate, drive seat, bridge bearing seat, pinion, reducer, coupling, motor, large gear, large liner, etc.

Ball mill real shot

Product Performance

- 1Easy installation and operation, stable operation

The machine adopts an integrated structure of the machine body and chassis. It can be hung on the basic plane at one time during installation, making operation and maintenance easier; the equipment has no inertial impact and runs smoothly, reducing the mill downtime and maintenance time and improving efficiency.

- 2Low energy consumption and high processing capacity

The main bearing adopts a large-diameter double-row spherical roller bearing to replace the original sliding bearing, which reduces friction, reduces energy consumption by 30%, increases fine particle size, and increases processing energy by 15%-20%.

- 3Good wear resistance and long service life of vulnerable parts

Vulnerable parts are cast with good wear-resistant steel, the hollow shaft is made of cast steel, and the lining is removable; the rotating large gear is processed by casting hobbing, and the cylinder is inlaid with wear-resistant lining, which has good wear resistance and longer service life of the equipment.

- 4Less dust, low noise, and green and environmentally friendly production

Install smoke filtration system, dust removal and noise reduction equipment to control dust and noise pollution within the standard range, and use grease spindle lubrication to avoid heavy metal pollution, fully realizing green and environmentally friendly production standards.

Working Principle

The ball mill is mainly composed of the feeding part, the discharging part, the rotating part, the transmission part, etc. Among them, the important parts include: the cylinder, the end cover, the bearing and the transmission gear ring. The main part of the ball mill includes the cylinder, which is lined with a wear-resistant material, and the bearing that can carry the cylinder and maintain its rotation. There are also driving parts, such as motors and transmission gears, V-belts, etc.

The ball mill cylinder is filled with steel balls or steel rods with a diameter of 25-150mm, which are called grinding media. The amount of balls should be 25%-50% of the entire cylinder volume, which is more reasonable. The end caps at both ends of the cylinder are connected to the flanges at the ends of the cylinder by screws. There is a hole in the middle of the end cap, which is called a hollow shaft neck. The hollow shaft neck is supported on the bearing. In addition, a large gear ring is fixed on the cylinder. In the drive system, the motor drives the large gear ring and the cylinder through the coupling, reducer and pinion gear to rotate slowly. When the cylinder rotates, the grinding medium will rise to a certain height with the cylinder, and then fall or fall down in a parabolic curve, thus completing the coordinated operation between the components.

The material is fed into the first bin of the mill evenly through the feeding device through the feeding hollow shaft spiral. The bin has a stepped lining or a corrugated lining, which is filled with steel balls of various specifications. The centrifugal force generated by the rotation of the cylinder brings the steel balls to a certain height and then falls, which produces a heavy impact and grinding effect on the material. After the material is roughly ground in the first bin, it enters the second bin through a single-layer partition plate. The bin is inlaid with a flat lining plate and steel balls to further grind the material. The powder is discharged through the discharge grate plate to complete the grinding operation.

Technical Parameters

| Specifications and models | Drum speed (r/min) | Ball loading (t) | Feed size (mm) | Discharge size (mm) | Output (t/h) | Motor power (kw) | Total weight (t) |

| Φ900 x 1800 | 36 | 1.5 | ≤20 | 0.075-0.89 | 0.65 - 2 | 18.5 | 5.5 |

| Φ900 x 3000 | 38 | 2.7 | ≤20 | 0.075-0.89 | 1.1- 3.5 | 22 | 6.7 |

| Φ1200 x 2400 | 36 | 3 | ≤25 | 0.075-0.6 | 1.5- 4.8 | 30 | 12 |

| Φ1200 x 3000 | 36 | 3.5 | ≤25 | 0.074-0.4 | 1.6-5 | 37 | 12.8 |

| Φ1200 x 4500 | 36 | 5 | ≤25 | 0.074-0.4 | 1.6-5.8 | 55 | 13.8 |

| Φ1500 x 3000 | 32.4 | 7.5 | ≤25 | 0.074-0.4 | 2-5 | 75 | 16.8 |

| Φ1500 x 4500 | 29.7 | 11 | ≤25 | 0.074-0.4 | 3-6 | 110 | 21 |

| Φ1500 x 5700 | 27 | 12 | ≤25 | 0.074-0.4 | 3.5-6 | 130 | 25.8 |

| Φ1830 x 3000 | 25.4 | 11 | ≤25 | 0.074-0.4 | 4-10 | 130 | 29 |

| Φ1830 x 4500 | 25.4 | 15 | ≤25 | 0.074-0.4 | 4.5-12 | 155 | 35.5 |

| Φ1830 x 6400 | 24.1 | 21 | ≤25 | 0.074-0.4 | 6.5-15 | 210 | 43 |

| Φ1830 x 7000 | 24.1 | 23 | ≤25 | 0.074-0.4 | 7.5-17 | 245 | 43.8 |

| Φ2100 x 3000 | 23.7 | 15 | ≤25 | 0.074-0.4 | 6.5- 36 | 155 Or 180 | 34.8 |

| Φ2100 x 4500 | 23.7 | 24 | ≤25 | 0.074-0.4 | 8- 43 | 245 | 42 |

| Φ2100 x 7000 | 23.7 | 26 | ≤25 | 0.074-0.4 | 8- 48 | 280 | 56.6 |

| Φ2200 x 4500 | 21.5 | 27 | ≤25 | 0.074-0.4 | 9- 45 | 280 | 51.8 |

| Φ2200 x 6500 | 21.7 | 35 | ≤25 | 0.074-0.4 | 14-26 | 380 | 60 |

| Φ2200 x 7000 | 21.7 | 35 | ≤25 | 0.074-0.4 | 15-28 | 380 | 62 |

| Φ2200 x 7500 | 21.7 | 35 | ≤25 | 0.074-0.4 | 15-30 | 380 | 64.8 |

| Φ2400 x 3000 | 21 | 23 | ≤25 | 0.074-0.4 | 7-50 | 245 | 58 |

| Φ2400 x 4500 | 21 | 30 | ≤25 | 0.074-0.4 | 8.5-60 | 320 | 69 |

| Φ2700 x 4000 | 20.7 | 40 | ≤25 | 0.074-0.4 | 12-80 | 40 0 | 94 |

| Φ2700 x 4500 | 20.7 | 48 | ≤25 | 0.074-0.4 | 12-90 | 480 | 102 |

| Φ3200 x 4500 | 18 | 65 | ≤25 | 0.074-0.4 | depends on process | 630 | 137 |

| Φ3600 x 4500 | 17 | 90 | ≤25 | 0.074-0.4 | depends on process | 10 00 | 158 |

| Φ3600 x 6000 | 17 | 110 | ≤25 | 0.074-0.4 | depends on process | 1250 | 175 |

| Φ3600 x 8500 | 18 | 131 | ≤25 | 0.074-0.4 | 45.8 - 256 | 1800 | 252 |

| Φ4000 x 5000 | 16.9 | 121 | ≤25 | 0.074-0.4 | 45 - 208 | 1500 | 203 |

| Φ4000 x 6000 | 16.9 | 146 | ≤25 | 0.074-0.4 | 65 - 248 | 1600 | 218 |

| Φ4000 x 6700 | 16.9 | 149 | ≤25 | 0.074-0.4 | 45 - 252 | 1800 | 238 |

| Φ4500 x 6400 | 15.6 | 172 | ≤25 | 0.074-0.4 | 54 - 306 | 2000 | 280 |

| Φ5030 x 6400 | 14.4 | 216 | ≤25 | 0.074-0.4 | 68 - 386 | 2600 | 320 |

| Φ5030 x 8300 | 14.4 | 266 | ≤25 | 0.074-0.4 | 88 - 500 | 3300 | 403 |

| Φ5500 x 8500 | 13.8 | 338 | ≤25 | 0.074-0.4 | 108 - 615 | 4500 | 525 |