Popular searched products:

Product Description

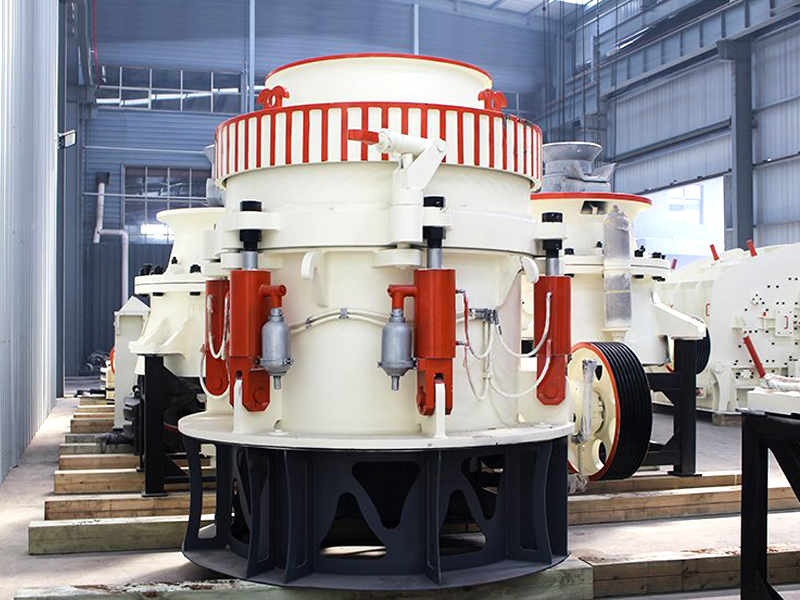

The HP series multi-cylinder hydraulic cone crusher is a product of our company that uses the efficient crushing principle of the cone crusher as the basis and adopts multi-cylinder hydraulic technology to upgrade some of the performance of the spring-type cone crusher and improve its structure; it is more convenient to use Economical and practical. This series of models is mainly suitable for crushing stones with a hardness not exceeding 300Mpa in hydropower, construction, road construction, mining and other industries. The crushing ratio is large, the efficiency is high, the energy consumption is low, and the product particle size is uniform.

Real shooting

Product Performance

- 1Adopts the principle of laminated crushing

The crushed products are mostly cubes, reducing needle-like materials; due to the optimization of the multi-cylinder hydraulic cone crusher The design reduces the failure rate of the equipment and greatly improves the work efficiency. It is one of the most widely used crushing equipment in China.

- 2Using full hydraulic operation, easy to use

Easy to realize automation, its reliability and service life are greatly improved. The hydraulic system can effectively ensure the safe operation of the equipment. When there is foreign matter in the crushing cavity, the hydraulic system can automatically make the movable cone move downward. When the foreign matter is discharged, the system will automatically reset the moved cone and maintain the position again. The original discharge port position continues to work.

- 3Adopts a labyrinth sealing device

replacing the water seal used in the past, effectively reducing the possibility of dust entering the equipment body, thereby ensuring the lubrication oil Cleaning prolongs the service life of sliding bearings and thrust ball bearings, making the machine operation safe and reliable.

- 4Reasonable structure, advanced crushing principles and technical parameters

Reliable operation, low operating costs; excellent equipment parts configuration, strong wear resistance, effective reduction of Maintenance costs are reduced and the service life of the equipment is extended by more than 30%.

Working Principle

When working, the rotation of the motor drives the pulley or coupling, transmission shaft and cone part to make the eccentric shaft perform periodic swing motion under the axis center line. After the material enters the crushing chamber from the material opening, it is subjected to The mutual impact, squeezing, grinding, and rubbing of the eccentric shaft and the rolling mortar wall produce a crushing effect. The hydraulic safety system can remove the faulty objects from the support sleeve and the top of the fixed cone through hydraulic pressure when the machine has an iron failure or is stuck in the machine. It plays a very good insurance role and greatly reduces the maintenance rate.

Technical Parameters

| Model | Diameter of moving cone (mm) | Cavity type | Feeding port size (mm) | Discharge opening size (mm) | Spindle speed (r/min) | Motor power (kw) | Output (t/h) | External dimensions (mm) | |

| Feeding size (mm) | Opening opening size (mm) | < /tr>||||||||

| SHQ300 | 910 | Fine Coarse | 83 159 | 102 175 | 9-22 13-38 | 580 | 75 | 48-96 65-168 | 2821 × 1880 × 2164 |

| SHQ400 | 1200 | Slim type | 127 | 131 | 9-31 | 485 | 110-160 | 68-192 | 2821 × 1974 × 2651 |

| Medium | 156 | 156 | 13-38 | 105-205 | |||||

| Coarse | 178 | 191 | 19-51 | 146-308 | |||||

| SHQ500 | 1395 | Slim type | 155 | 173 | 25-65 | 485 | 220-250 | 180-290 | td>3360 × 2650 × 3050 |

| Medium | 188 | 198 | 22-50 | 220-335< /td> | |||||

| Coarse | 230 | 245 | 19-45 | 235-575 | |||||

| SHQ600 | 1650 | Slim type | 188 | 209 | 16-38 | 485 | 250-280 | 186-332 | 3911 × 2870 × 3771 |

| Medium | 213 | 241 | 22-51 | 263-422 | |||||

| Coarse | 241 | 268 | 25-64 | 304-640 | |||||