Hubei basalt sand production site

Production Capacity:200t/h

Processing materials:玄武岩、花岗岩、石灰石

Power Consumption:暂无数据

Production Capacity:200t/h

Processing materials:玄武岩、花岗岩、石灰石

Power Consumption:暂无数据

Global Heavy industry quality is good

Production capacity: about 200 tons per hour

Crushed material: basalt

Feeding particle size: ≤700mm

Discharge size: 0-5-10-20mm

Uses of finished products: road and railway construction, building construction, local market demand

1. Low dust and noise pollution: Dust reduction and dust collectors are necessary. When the material is dry and the wind is strong, a spray device is equipped. This device can humidify and increase the weight of the material to avoid flying dust. If necessary, it can The basalt sand making production line is configured as a fully enclosed or semi-enclosed type (fully enclosed: all equipment is configured in a closed shed, semi-enclosed: the conveyor belt is configured as a closed type, and other devices are configured as an open type). Sound insulation and noise reduction devices can be configured, and noise buffering devices can also be configured at the noise source.

2. Compact process, high degree of automation, and low post-operation cost: combined with user site conditions and processing needs, reducing the configuration of unnecessary equipment, achieving high productivity and low-cost operations, and configuring advanced automated operating systems to achieve less manual operations , stronger imported wear-resistant materials also greatly reduce the failure repair rate of the equipment, which can effectively reduce later maintenance costs.

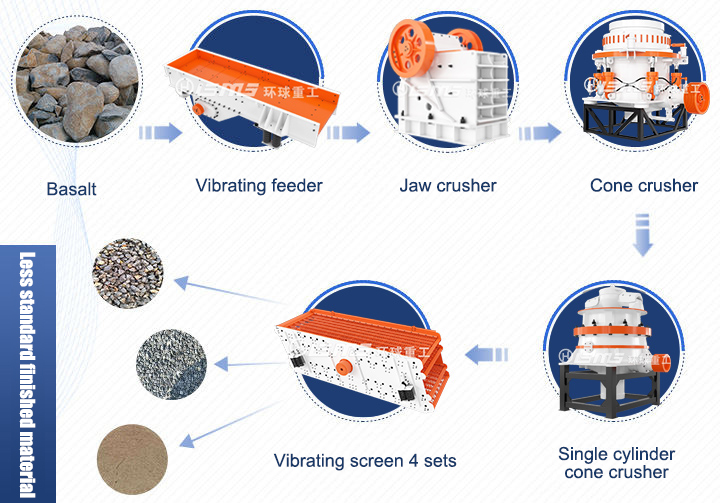

The processing of basalt is divided into three stages: coarse crushing by jaw crusher, medium and fine crushing by impact crusher or cone crusher, and sand making and shaping by sand making machine.

The first stage: coarse crushing

Basalt bulk materials are evenly fed by a vibrating feeder through the silo and transported to the jaw crusher for coarse crushing. After the coarsely crushed materials are screened by the vibrating screen, they are transported to the impact crusher by a belt conveyor. machine or cone crusher for medium and fine crushing.

The second stage: medium to fine crushing

After medium and fine crushing, the basalt transported to the impact crusher/cone crusher is screened using a circular vibrating screen, and larger particle materials are returned to the impact crusher/cone crusher for re-crushing.

The third stage: sand making

Send the crushed basalt to the sand making machine for further crushing and shaping. If clean basalt is needed, it can be sent to the sand washing machine for cleaning.

The fourth stage: packaging

Package and store the dried finished materials.

This basalt production line not only takes into account the production cost of our entire production line, but also considers the investment cost of the entire sand making project. Generally speaking, the investment funds are reasonable, and it operates with a high degree of automation. Now it is So far, the equipment has not experienced any major malfunctions. The finished product grain shape or size is very good, the production efficiency has exceeded expectations, and the production capacity is also great. I really chose the right manufacturer.