Popular searched products:

Product Description

The high-efficiency vertical shaft impact crusher, also known as a sand making machine, is the result of a new design by Global Heavy Industries engineers based on China's working conditions. This machine is specially designed to provide high-quality sand and gravel aggregates for highways, high-speed railways, high-rise buildings, municipal projects, hydropower dam construction, and concrete mixing stations. It is an equipment in the field of artificial sand making and stone shaping. It is widely used for medium and fine crushing (sand making) of various hard and brittle materials such as rocks, abrasives, refractory materials, cement clinker, quartz stone, iron ore, concrete aggregates, etc.

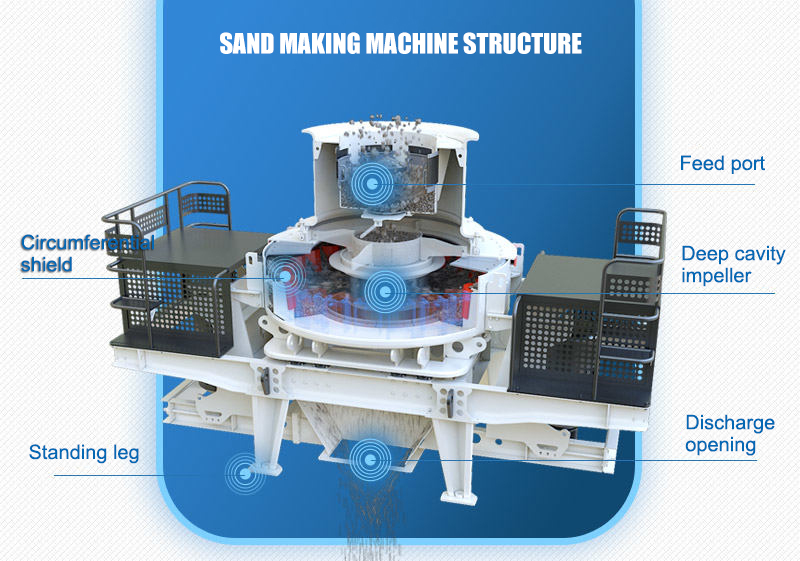

The impact sand making machine has a reasonable structural design and is famous for its simplicity and high efficiency. It mainly consists of a feed, a distributor, a vortex crushing chamber, an impeller, a spindle assembly, a base transmission device and a motor. It has a wide range of applications and can It can crush a lot of materials and is an indispensable equipment for producing high-quality machine-made sand.

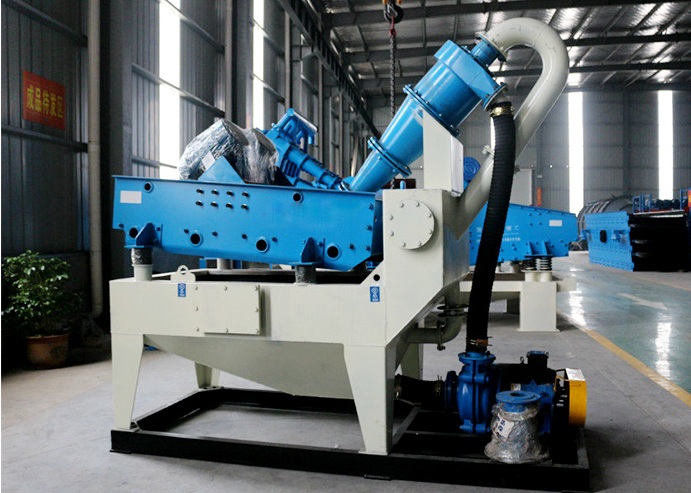

Physical display

Product Performance

- 1Optimized design to increase material throughput

The reasonable launch port and internal smooth curve design reduce the flow resistance to materials, and the deep cavity rotor After optimized design, the material throughput capacity has been greatly improved, increasing the material throughput by about 30%.

- 2One machine with multiple functions and flexible application

The unique feed crushing structure has a variety of crushing cavity types, which can easily achieve "stone against stone" and The conversion of the two crushing methods of "stone striking iron" enables one machine to be used for multiple purposes.

- 3 Small wear of components and low cost of use

After the peripheral protective plate is partially worn, the upper and lower heads can be rotated for use, which improves material utilization and extends the service life 48 %above. The combined hammer head design only needs to replace the worn hammer head part, which can reduce the use cost by more than 30%.

- 4Quality assurance, safe to use

The core wear-resistant materials are highly wear-resistant and high-temperature resistant materials used in important industries in the United States. The bearings are from Japanese, Swedish, and American brands, and a high-protection motor that meets the standards of the Electrotechnical Commission is selected.

Working Principle

The vertical shaft impact sand making machine uses the high-speed running materials to crush each other by themselves and the friction between the materials. The working mode can be divided into two crushing modes: "stone against stone" and "stone against iron". When the material enters the rotor and is accelerated by centrifugal force, it is thrown out and collides with the surrounding protective plate. The surrounding protective plate collides and rebounds, forming a cyclic impact. As the crushing progresses, small particles of material gradually form a material layer near the surrounding protective plate, which improves the crushing effect and protects the equipment. The finished materials that meet the specifications are discharged from the discharge port.

Technical Parameters

| Model number | Hard material | Soft material | Sand making | Plastic surgery | Motor power (kw) |

| Maximum feed size (mm) |

Throughput (t/h) |

||||

| HVI 0815 | <30 | <35 | 50-140 | 90-230 | 2×75 |

| HVI 0818 | <30 | <35 | 60-190 | 110-283 | 2×90 |

| HVI 0922 | <35 | <40 | 70-210 | 150-330 | 2×110 |

| HVI 0926 | <35 | <40 | 85-240 | 170-380 | 2×132 |

| HVI 1032 | <40 | <45 | 130-278 | 180-356 | 2×160 |

| HVI 1040 | <40 | <45 | 180-284 | 250-440 | 2×200 |

| HVI 1263 | <50 | <55 | 320-498 | 370-585 | 2×315 |