Popular searched products:

Product Description

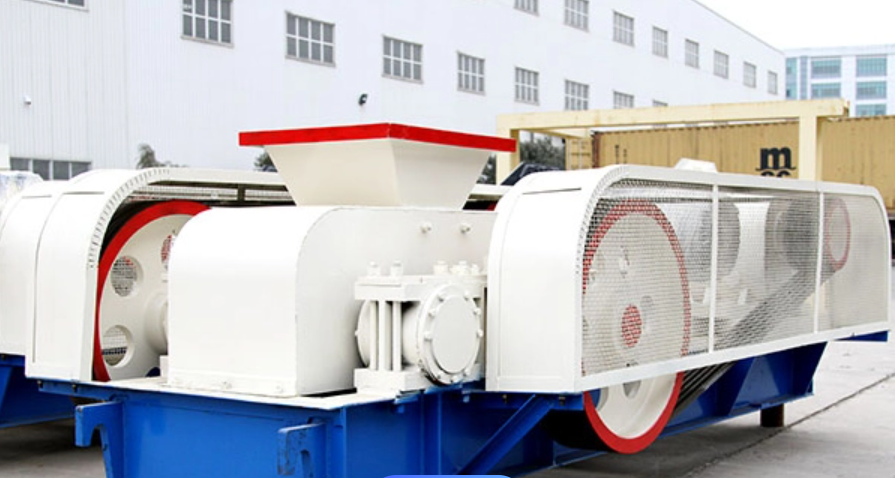

Compared with the traditional jaw crusher, the SD German version of the jaw crusher has been greatly improved in terms of motion parameters, machine structure, and adjustment methods. The integrated structural design of the motor base and main machine makes the machine take up less space and run more smoothly. It has more advantages in transportation, installation, maintenance and adjustment, and is especially suitable for fixed production lines and mobile crushing. The crushing chamber adopts a symmetrical "V" design, with a large inclination angle of the toggle plate, a large stroke, and a reasonable rotation speed, which results in larger feed particle size, higher output, and more uniform particle size. The wear of the jaw plate is reduced, and the machine maintenance rate and failure rate are reduced. The service life is extended and the overall cost is lower.

Jaw crusher, also called jaw crusher, is mainly used for primary crushing of various ores and bulk materials. The feeding range is 125-1200mm, and the discharge opening adjustment range is 10-350mm. A single jaw crusher The machine's production capacity can reach up to 1,000 tons/hour. It is widely used in mining, smelting, building materials, highways, railways, water conservancy and chemical industries. It can process quartz stone, bluestone, river pebbles, cobbles, limestone, iron ore and other stones. Processing and crushing.

SD German version jaw crusher live shot

Product Performance

- 1Integrated design, small space occupied

The integrated structure design of the motor base and the main machine makes the machine take up less space, run more smoothly, and is easy to transport. Installation and maintenance adjustments.

- 2Oversized bearing design, stronger load-bearing capacity

The bearing seat adopts an integral cast steel structure, the bearing size is increased, the load-bearing capacity is stronger, and the use is extended life.

- 3The discharge port is adjustable and flexible to use

The discharge port adopts a wedge-type adjustment device, which has a large discharge adjustment range and increases the flexibility of the equipment. , which can meet the needs of different users.

- 4Stable structure and reliable performance

The movable jaw assembly is made of high-quality steel castings, and the heavy-duty eccentric shaft is processed from segment billet, making the equipment unique Extraordinary reliability and durability.

Working Principle

When the crusher is working, the motor drives the eccentric shaft to rotate through the pulley, causing the movable jaw to periodically approach and leave the fixed jaw, thereby squeezing, rubbing, grinding and other multiple crushing processes for the material, making the material change from large to small, and gradually Fall until it is discharged from the discharge port to complete the crushing.

Technical Parameters

| Model | Feeding port size (mm) | Maximum feed particle size (mm) | Discharge port range (mm) | Production capacity (t/h) | Motor power (kw) | Outline dimensions (mm) |

| SD72(57) | 460x720 | 425 | 45-100 | 50-120 | 6P 55 | 1566x1965x1630 |

| SD86(69) | 580x860 | 500 | 50-150 | 60-210 | 8P 75 | 1722x1943x1810 |

| SD98(751) | 680x980 | 630 | 75-175 | 110-330 | 8P 110 | 1960x2470x2180 |

| SD110(912) | 850x1100 | 750 | 100-200 | 230-450 | 6P 132 | 2381x2775x2500 |

| SD125 | 950x1250 | 900 | 125-225 | 280-750 | 8P 160 | 2600x3320x3120 |