Popular searched products:

Large hydraulic roller crusher is a kind of crushing equipment, mainly used in mining, coal, metallurgy, chemical industry, building materials and other industries to crush various hard materials and make sand. The core features of large hydraulic roller crushers are as follows:

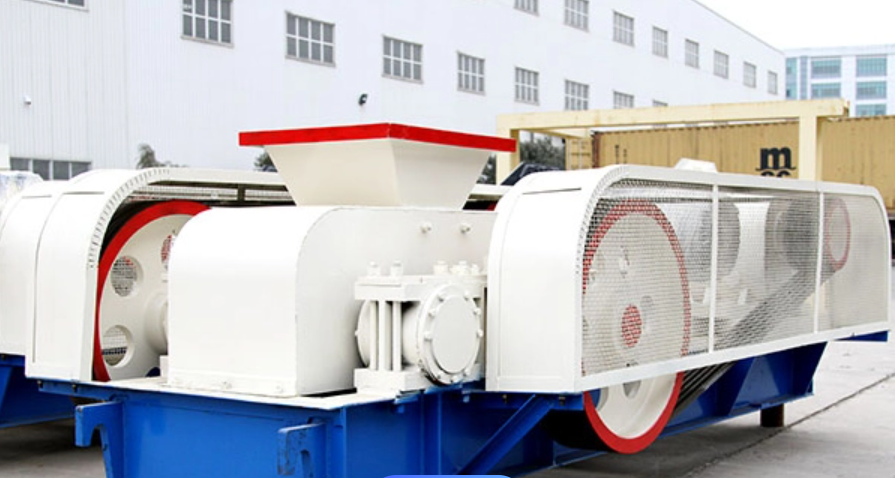

Large hydraulic roller crusher

Structural design: Large hydraulic roller crushers usually consist of two relatively rotating crushing rollers. They rely on the hydraulic system for drive and adjustment to ensure stable and reliable operation of the equipment. The hydraulic system can accurately adjust the gap between the two rollers to adapt to the crushing needs of materials with different particle sizes.

Working principle: The material is squeezed, sheared and broken between the two rollers. The particles produced by this crushing method have regular shapes, uniform particle sizes, and high crushing efficiency.

Energy efficiency: Hydraulic drive technology makes the equipment consume less energy, effectively controls energy consumption, and reduces energy waste during the crushing process.

Degree of automation: Equipped with an electrical control system to realize automated operation and control of equipment, improve production efficiency, and reduce manual intervention and operational risks.

Large hydraulic roller crusher

Maintenance and safety features: The hydraulic roller crusher has a relatively simple structure and is easy to maintain and repair. At the same time, the overload protection function of the hydraulic system enhances the safety of the equipment and avoids damage to the equipment due to excessive material or other abnormal conditions.

Wide range of applications: In addition to being suitable for crushing a variety of ores, it can also be used for crushing and sand-making operations of hard and brittle materials such as coal and cement clinker. It is especially suitable for occasions where the material processing volume is large and the particle size of finished products is strictly controlled.

Related Reading

- Operation plan of mud treatment system in sand washing field

- Sand washing wastewater treatment technology helps you achieve zero discharge of sand washing wastewater

- These advantages make the sand washing machine the preferred equipment in the sand washing industry!

- If you want to choose a cost-effective truck-mounted mobile sand washing machine, Zhengzhou Global Heavy Industry is your first choice

Product show

Product

Source:

Source: Time:2024/04/25 11:04:08

Time:2024/04/25 11:04:08