Popular searched products:

Product Description

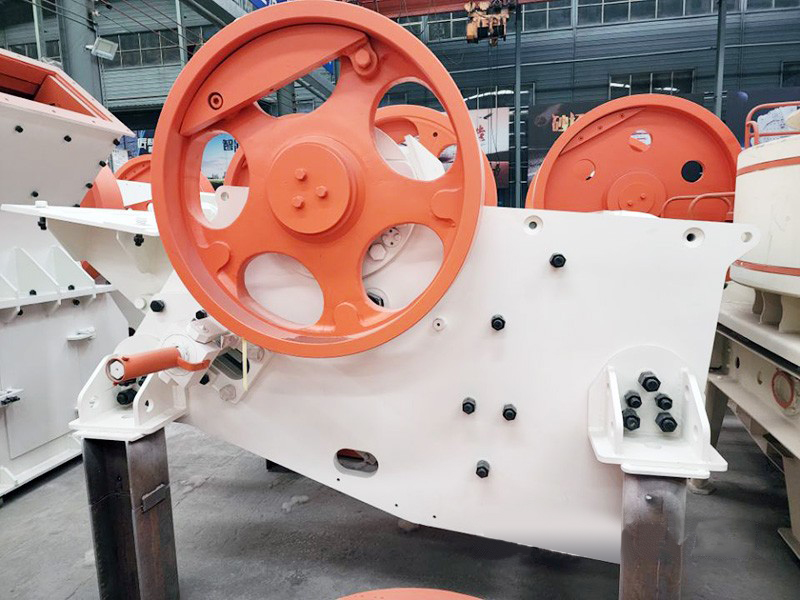

In the mining and construction crushing industry, jaw crushers are at the front end of the production line. They can perform coarse and medium crushing on hard and highly abrasive ores and rocks, and are the first process for crushing various ores and rocks. The SC series jaw crusher is a new generation of jaw crushers developed by our company with the introduction of advanced foreign technology. It uses better raw materials and key components provided by high-level manufacturers at home and abroad. It has the advantages of high output, low energy consumption, reliable structure, easy operation and maintenance, and long service life. It is widely used in crushing ores, rocks, slag, etc. with a compressive strength not higher than 300MPa.

Product Performance

- 1High standard configuration

High-quality raw materials and reliable design provide SC jaw crusher with sufficient equipment strength and durability for crushing superhard materials, and reduce maintenance costs.

- 2High-quality casting and forging ensure equipment reliability

Core rotating parts such as high-quality cast movable jaw body, large eccentricity heavy forged eccentric shaft, high moment of inertia cast flywheel and high-strength integral cast steel bearing box, strong power and reasonable equipment speed ensure stable production of equipment.

- 3Easy to maintain and improve equipment operation rate

The equipment adopts centralized grease lubrication, and can be configured with manual or automatic grease lubrication system as needed to reduce the difficulty of maintenance.

- 4Original parts supply, worry-free operation

We are responsible for every piece of equipment we produce, providing customers with technical services and original parts supply services throughout the product life cycle, ensuring that every customer has no worries in production

Working Principle

The crushing method of jaw crusher is flexural extrusion type, which is mainly composed of frame, eccentric shaft, large pulley, flywheel, side guard plate, toggle plate, toggle plate back seat, gap adjustment screw, reset spring, fixed jaw plate and movable jaw plate. SC jaw crusher is usually driven by motor as the power source. When working, the motor drives the belt and pulley, and the movable jaw moves up and down through the rotation of the eccentric shaft. When the movable jaw rises, the angle between the toggle plate and the movable jaw increases, thereby pushing the movable jaw to approach the fixed jaw plate. At the same time, the material is crushed or split to achieve the purpose of crushing. When the movable jaw moves downward, the angle between the toggle plate and the movable jaw becomes smaller, and the movable jaw plate leaves the fixed jaw plate under the action of the pull rod and spring. At this time, the crushed material is discharged from the lower part of the crushing chamber. As the motor rotates continuously, the crusher performs periodic movements to crush the material and discharge it, thus achieving batch production.

Technical Parameters

| Model | Feed port(mm) | Yield(t/h) | Power(kw) | Fixed line special |

| SC80 | 800X510 | 65-380 | 75 | |

| SC100 | 1000X760 | 150-545 | 110 | |

| SC110 | 1100X850 | 190-625 | 160 | |

| SC125 | 1250X950 | 290-845 | 160 | |

| SC140 | 1400X1070 | 385-945 | 200 | |

| SC160 | 1600X1100 | 520-1275 | 250 | |

| SC96 | 930X580 | 120-455 | 90 | Mobile breaker |

| SC106 | 1060X700 | 155-580 | 110 | |

| SC116 | 1150X800 | 170-600 | 132 | |

| SC120 | 1200X870 | 303-529 | 160 |