coal gangue crushing and sand making production site with an output of 500 tons per hour

Production Capacity:500t/h

Processing materials:gangue

Power Consumption:No data

Production Capacity:500t/h

Processing materials:gangue

Power Consumption:No data

Global Heavy industry quality is good

Coal gangue is a solid waste discharged during the coal mining process and coal washing process, gangue washing in coal washing plants, hand selection gangue in coal production, coal and rocks discharged from semi-coal tunnel and rock tunnel excavation, and together with coal gangue A mixture of white gangue and other materials piled outside the coal system. Coal gangue is divided into clay rock, sandstone, carbonate and aluminous rock according to its main mineral content. It is a black-gray rock with lower carbon content and harder than coal that is associated with coal seams during the coal formation process. The application range is extremely wide and the utilization rate is high. Especially through mining equipment processing, the value of coal gangue is greatly increased. However, old coal gangue pollutes the atmosphere. Coal gangue stacked in the open will produce a large amount of dust, which requires us to place it reasonably.

Feeding particle size: ≤800mm

Finished product specifications: 0-5 mm, 5-10 mm, 10-20mm, 10-30mm

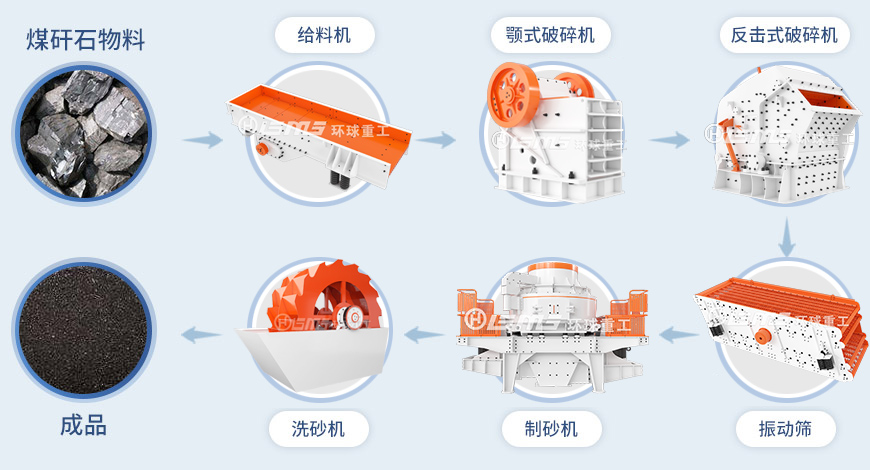

Equipment matching: feeder + jaw crusher + impact crusher + circular vibrating screen + conveyor + sand making machine + sand washing machine

Finished product of crushed coal gangue

This crushing production line is mainly designed based on the material characteristics, feeding and discharging conditions of coal gangue. The processed coal gangue is of high quality, with uniform particles and good particle shape. It has a higher degree of coordination and reduces waste of resources. The particle size can be freely controlled. Moreover, the production line has strong adaptability, allowing customers to operate it with high efficiency even on snowy days. The equipment has reliable quality, low failure rate, and no dust or noise. It has a good environmental protection effect and saves energy and consumption.

1. Large pieces of coal gangue are evenly fed by a vibrating feeder and transported to the jaw crusher through a conveyor for coarse crushing. The coarsely crushed coal gangue is screened by a vibrating screen;

2. The screened materials need to be crushed twice. The materials are transported to the impact crusher for crushing, and the circular vibrating screen is used for screening. The larger particles of coal gangue are returned to the impact crusher for re-crushing;

3. Send the secondary crushed coal gangue to the sand making machine for further crushing and shaping to make the granular shape more uniform and aesthetic; then send the material to the sand washing machine for cleaning, and clean the finished product Coal gangue particles are packaged and stored.