Marble crushing production site with an output of 300 tons per hour

Production Capacity:300t/h

Processing materials:大理石、花岗岩、玄武岩、石灰石

Power Consumption:暂无数据

Production Capacity:300t/h

Processing materials:大理石、花岗岩、玄武岩、石灰石

Power Consumption:暂无数据

Global Heavy industry quality is good

Marble originally refers to limestone with white stripes and black patterns produced in Dali. It is a rock formed after long-term high temperature and high pressure. Very common in daily life. Mainly composed of calcium carbonate, it is soft in nature and brings you a different visual feast in appearance. It is very popular in hotels, walls, rubber, infrastructure and other industries.

Feeding particle size: 100-1020mm

Output: 300t/h

Finished product specifications: 5-10-20-31.5-65mm

1. High degree of automation, low operating costs, less powdery materials produced, good grain shape of finished products, large output, and high profits.

2. The discharge particle size is adjustable, and various specifications meet the needs of different users. The gradation is reasonable, the quality of the finished product is easier to control, and it reaches high quality standards. It is more widely used in high-intensity processing such as concrete and dry-mixed mortar.

3. During the operation of the production line, there is little noise, less dust, little impact on the production environment, good environmental protection and energy saving effects, in line with relevant national standards, and sustainable development.

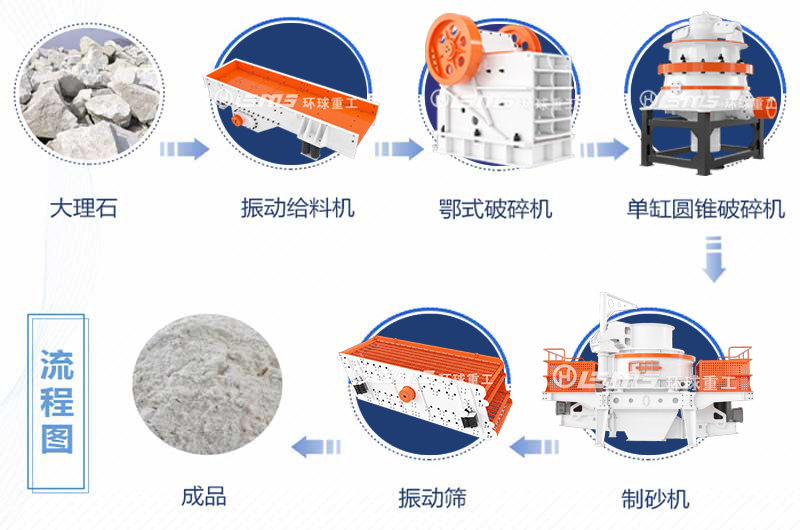

The marble sand making process generally includes crushing, screening, sand making, sand washing, etc., which requires the use of crushing equipment, feeding equipment, conveying equipment, sand making equipment, sand washing equipment, etc.

1. Coarse crushing: The texture of marble is relatively hard, and the efficiency of directly using it to make sand is not high, and the damage to the sand making equipment is relatively large, so it should be crushed first. The primary crushing can be done through the jaw crusher. Various block-shaped marbles have uniform particle sizes, which meet the requirements of the inlet of the sand making machine. The output is large, the crushing ratio is large, the product particle size is uniform, the price of the equipment is low, and the investment cost is small.

2. Medium and fine crushing: Use cone crusher, new crusher structure, optimized laminated crushing chamber type to achieve large production capacity and high crushing efficiency. In addition, it also has the characteristics of automation and intelligence, high production safety and good environmental performance. It is suitable for customers with hard materials and high output requirements, but not high requirements on particle shape.

3. Fine crushing: Sand making machine, HVI sand making machine and VSI sand making machine can be used. It has high throughput, long service life, wide adaptability, and the finished product has good grain shape and uniform size, which can be used for construction, Water conservancy and other industries provide high-quality sand and gravel aggregates. It can effectively reduce the amount of sand making dust and create a green sand making environment for users. In addition to crushing, the sand making machine has a shaping effect, and the finished product is of high quality and is a sand and gravel material that meets national standards.

4. Sand washing: Use wheel bucket sand washing machine, which has large output, low equipment price, energy saving, and water can be recycled.

5. Other equipment: vibrating feeders, vibrating screens, conveyors, etc. are also needed.

We are very satisfied with this limestone production line. Because its operating status is very stable and easy to maintain, the output can also reach my target (about 300 tons/hour), and the finished product is uniform in size and good in grain shape. The service provided by Global Heavy Industries is very considerate. From the selection and transportation of equipment to the installation of machines in my limestone crushing plant, professional technicians follow up and report the situation to me.