Popular searched products:

Product Description

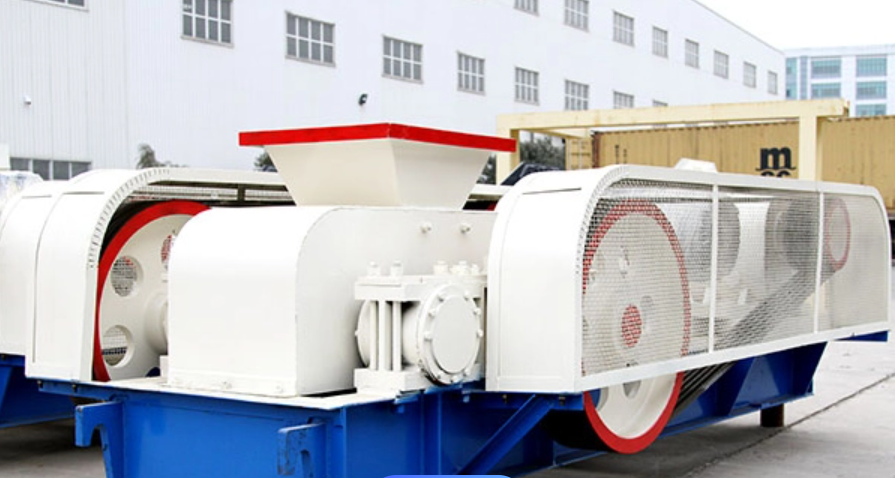

The fine crushing, shaping and screening mobile station is equipped with VSI series and 5X series impact crushers with high performance, large crushing ratio and powerful crushing. It is an ideal equipment in the field of artificial sand making and stone shaping, and can make the crushed finished products have a reasonable gradation. Two mobile stations equipped with VSI series and two equipped with 5X series impact crusher + vibrating screen fine crushing, shaping and screening are available.

Mobile sand making machine

Product Performance

- 1Integrated complete generator set

Integrated complete generator set, effective and compact space planning, maximize the space of the site and eliminate the need for separation The complex infrastructure construction and installation work of integrated components reduces the consumption of raw materials and total man-hours, and expands the space for raw material accumulation and shipping.

- 2Strong controllability, time-saving, labor-saving and cost-effective

The vehicle-cut traction belt can be used for timely and safe work on the spot, eliminating the need to transport the raw materials away from the site and then crush them stage, greatly reducing the transportation cost of raw materials. In addition, due to the high chassis and small minimum turning radius of the car, it can be driven freely on ordinary roads and difficult and dangerous roads, and can quickly settle into the scene.

- 3Flexible configuration and strong adaptability

Features make up the generator set configuration, which can allow a single generator set to operate safely alone, or it can be flexibly configured to work together safely. To meet various requirements of customers such as mobile crushing and mobile screening to control costs.

- 4Reliable performance and convenient maintenance

The entire set of generator equipment is equipped with our company’s intelligent, high-efficiency, high-quality crusher equipment. The lightweight and effective design, excellent crushing performance, and reliable and stable product quality meet the requirements of coarse and medium crushing to a great extent.

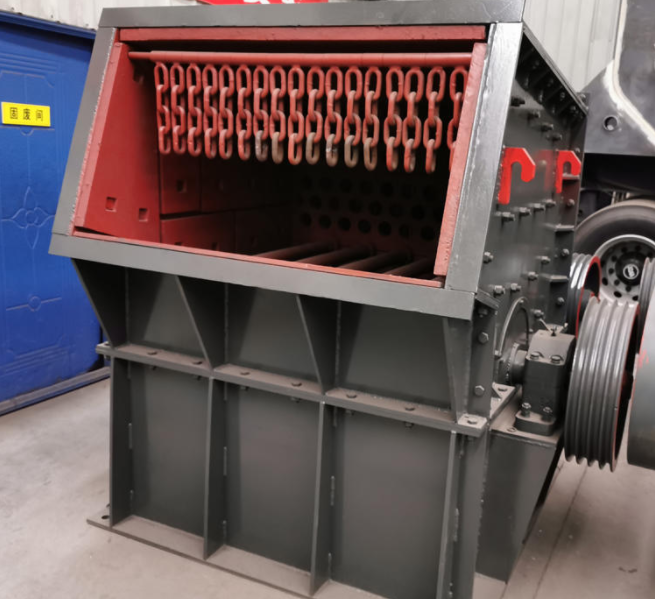

Working Principle

The working principle of the impact mobile crushing station is the same as that of the impact sand making machine. The material enters the sand making machine from the feed hopper and is divided into two parts through the distributor. One part enters the high-speed rotating impeller from the middle of the distributor. It is rapidly accelerated in the impeller, and its acceleration can reach hundreds of times the acceleration of gravity, and then is thrown out from the three uniform flow channels of the impeller at a speed of 60-70 meters/second. A part of the material is impacted and broken, and then hits the material lining in the scroll chamber together. It is rebounded by the material lining, impacts diagonally upward to the top of the vortex chamber, changes its direction of movement, deflects downward, and is launched from the impeller flow channel. The material coming out forms a continuous material curtain. In this way, a piece of material will be hit, rubbed, grinded and crushed twice or even multiple times in the whirling crushing cavity. The crushed materials are discharged from the lower discharge port. It forms a closed circuit with the circulating screening system. Generally, the material can be broken into less than 20 mesh after three cycles. During the entire crushing process, the materials impact and crush each other on their own, without direct contact with metal components. Instead, they are crushed by impact and friction with the material lining, which reduces corner contamination and prolongs mechanical wear time. The clever self-circulation of air flow inside the vortex chamber eliminates dust pollution.

Technical Parameters

| Standard model | Supporting equipment | Supporting equipment | External dimensions (mm) | ||

| Model | Feeding particle size (mm) | Processing capacity (t/h) | |||

| S-V7611 | 3YZK1548 | VSI7611 | 35 | 120-180 | 12500 x 2600 x 4300 |

| S-V8518 | 3YZK1848 | VSI8518 | 40 | 200-260 | 14200 x 3000 x 4500 |

| S-V9526 | 3YZK1860 | VSI9526 | 45 | 300-380 | 14500 x 3000 x 4500 |

| S-V1140 | 3YZK2160 | 5X1140 | 50 | 450-520 | 15500 x 3100 x 4500 |

| S-5V7615 | 3YZK1548 | 5X7615 | 35 | 150-280 | 12500 x 2600 x 4300 |

| S-5V8522 | 3YZK1848 | 5X8522 | 40 | 240-380 | 14200 x 3000 x 4500 |

| S-5V9532 | 3YZK1860 | 5X9532 | 45 | 350-540 | 14500 x 3000 x 4500 |

| S-5V1145 | 3YZK2160 | 5X1145 | 50 | 500-640 | 15500 x 3100 x 4500 |