Popular searched products:

Product Description

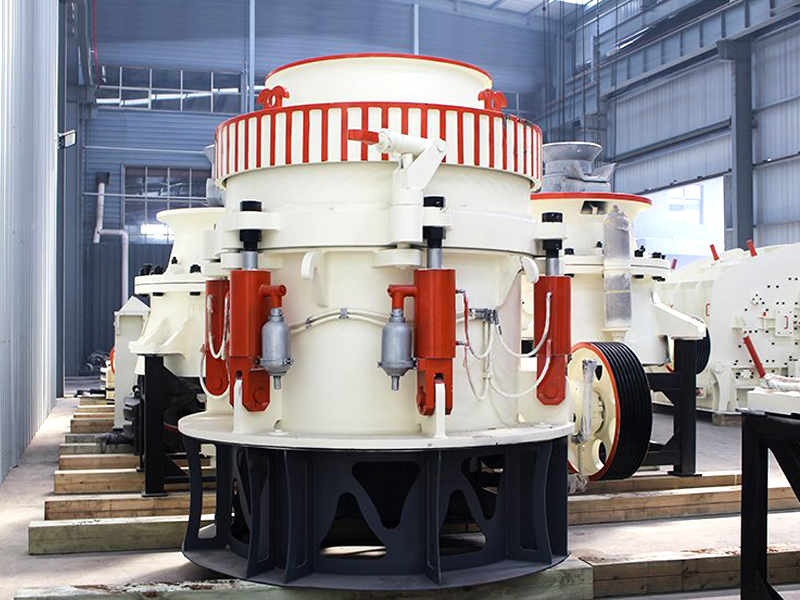

The three-combination mobile station is a good choice for small and medium-sized production needs, frequent mobile working environments, and independent completion of customer stone production needs. According to the customer's discharge particle size and particle shape requirements, three combinations of two types equipped with impact crushers and two types equipped with jaw crushers are available to meet customer groups with different needs. The three-combination jaw crusher model can not only meet the customer's stone production needs independently, but can also be used for rough crushing in online operations.

Large diameter impact mobile crushing station

Three combination mobile crushing station

Product Performance

- 1Strong maneuverability

The vehicle has a compact structure, a small turning radius, low requirements for road transportation conditions, and is convenient and quick to change and enter and leave the site;

1 p>

- 2Reduce transportation costs

It can be opened directly to the site, and the raw materials can be processed and crushed on site, which reduces the transportation links of raw materials and saves the transportation of raw materials. Cost;

- 3Integrated unit

Integrated combined operation mode integrates feeding, crushing, screening, conveying and other processes into one, and the material can be discharged directly Meet customer requirements, the operation method is direct and effective;

- 4Saving investment costs

According to different raw materials and process requirements, the host can be directly replaced without changing the body to meet different stages of crushing and screening. demand, saving investment costs;

Working Principle

The impact crusher and jaw crusher interchange system has a body that is common to 4 models. The feeding unit interchange system, crushing unit interchange system and screening unit interchange system only need to invest in the cost of single machine equipment, and the short-term Within a short period of time, different types of feeding unit interchange systems, impact crusher and jaw crusher interchange systems, and different types of vibrating screen interchange systems can be implemented on the same body. The systems of the whole machine are well matched and adaptable to a wider range of occasions. , the crushing performance is more stable, and the customer's consumer goods are fully reflected. Some configurations of this module are optional with a full vehicle-mounted belt conveyor.

Technical Parameters

| Standard model | Supporting equipment | Supporting equipment | External dimensions (mm) | ||

| Model | Feeding particle size (mm) | Processing capacity (t/h) | |||

| S-PF1214-S18 | 3YZK1860 | PF1214 | ≤300 | 100-200 | 16400 x 2810 x 4500 |

| ZSW9638 | |||||

| S-PF1315-S21 | 3YZK2160 | PF1315 | ≤350 | 130-280 | 16900 x 3000 x 4500 |

| ZSW4211 | |||||

| S-LF150-S18 | 3YZK1848 | LF150 | ≤600 | 90-200 | 14800 x 2710 x 4500 |

| ZSW9638 | |||||

| S-LF250-S21 | 3YZK2160 | LF250 | ≤800 | 180-250 | 16000 x 3000 x 4500 |

| ZSW4211 | |||||

| S-PCZ1308-S18 | 3YZK1860 | PCZ1308 | ≤500 | 100-160 | 13800 x 2500 x 4200 |

| ZSW9638 | |||||

| S-PCZ1512-S22 | 3YZK2260 | PCZ1512 | ≤700 | 200-350 | 15000 x 3000 x 4500 |

| ZSW4211 | |||||