Popular searched products:

Product Description

The four-combined portable rock crusher usually includes two modules: coarse crushing and screening and fine crushing. It completes the four tasks of uniform feeding, coarse crushing, screening and classification, and fine crushing. Therefore, the vehicle body is long. The four-combination portable rock crusher basically completes the tasks completed by a set of fixed crushing production lines.

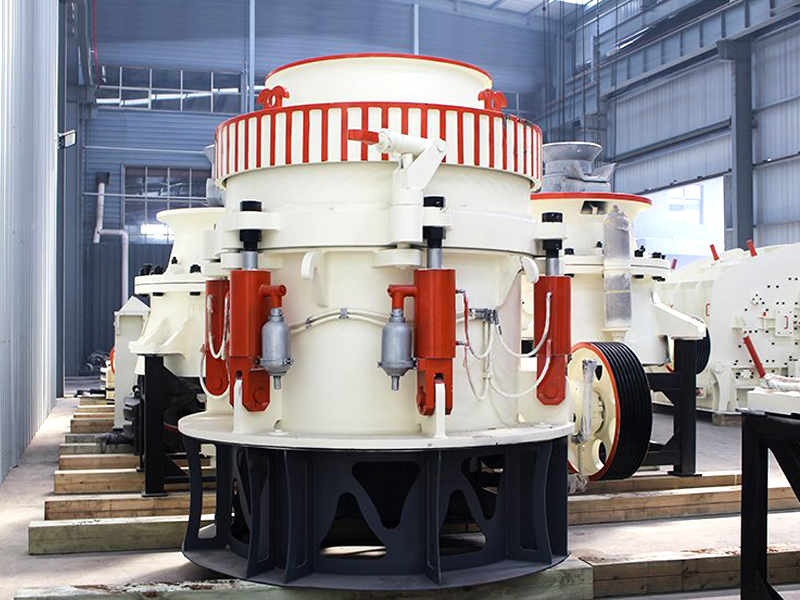

The four-combination portable rock crusher can be used in mining, building materials, solid waste treatment, chemical industry and other industries. The main direction is sand and gravel processing, which is more suitable for crushing projects that need to follow the project. Our company provides primary crushing jaw crusher according to the customer's feed particle size and discharge particle size requirements. The secondary crusher is equipped with eight models of cone crusher and impact crusher to choose from. Customers can combine them independently according to the finished product requirements.

Product Performance

- 1Mobility saves material transportation costs

The vehicle has a high chassis, compact structure, convenient transportation, and small turning radius, making it easy to drive on ordinary highways and more It is convenient to drive in the rugged and harsh road environment of the crushing site;

- 2Integrated crushing and screening

The integrated unit equipment installation form eliminates the complicated site infrastructure installation work of separate components and reduces the cost of materials, Man-hour consumption; the unit’s reasonable and compact space layout improves the flexibility of site deployment;

- 3Intelligent operation, saving costs

All operations of the portable rock crusher are controlled by an intensive hydraulic system, and only one person can set up the machine quickly and easily The operation action is easy to operate and can save a lot of labor costs;

- 4Flexible combination to meet different needs

We can flexibly configure secondary crushing according to the needs of different customers, and optimize the combination of crushing and screening , to meet the personalized needs of customers to a great extent;

- 5Hybrid oil and electricity, continuous operation without disconnection

The equipment can be powered by a mixture of oil and electricity, and can switch operating modes with one click to meet the needs of offline operations. Under complex conditions such as power outages or power outages, the equipment can continue to operate and produce normally;

Working Principle

The four-combination portable rock crusher workbench is self-assembled according to the needs of coarse, medium and fine finished products. It is economical, suitable for medium and small batches, and has its own load-type conveyor screening. The four combined portable rock crusher stations include a primary crushing station, a secondary crushing and screening station, a feeder, a belt conveyor, a screening system, etc. Each level of crushing station has its own role, and they work independently. Units also collaborate with each other to complete work together.

Technical Parameters

| Standard model | Supporting equipment | Supporting equipment | External dimensions (mm) | ||

| Model | Feeding particle size (mm) | Processing capacity (t/h) | |||

| S-E46-PF1007 | 3YZK1237 | PE400×600 | ≤350 | 30-50 | 12500 x 2500 x 4500 |

| GZD650×2300 | PF1007 | ||||

| S-E57-PF1010 | 3YZK1545 | PE500×750 | ≤425 | 50-100 | 13000 x 2500 x 4500 |

| ZSW850×3000 | PF1010 | ||||

| S-E69-PF1214 | 3YZK1848 | PE600×900 | ≤500 | 100-180 | 15800 x 2550 x 4500 |

| ZSW9638 | PF1214 | ||||

| S-E57-Q300 | 3YZK1545 | PE500×750 | ≤425 | 50-100 | 13000 x 2500 x 4500 |

| ZSW850×3000 | HP200 | ||||

| S-E69-Q400 | 3YZK1860 | PE600X900 | ≤500 | 100-180 | 15800 x 2550 x 4500 |

| ZSW960 x 3800 | HP300 | ||||