Popular searched products:

Product Description

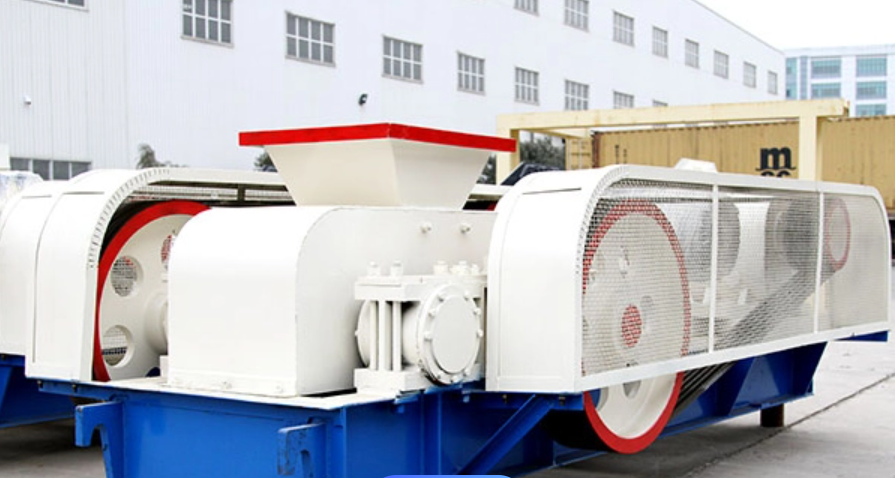

The mobile jaw crushing station is a mobile crushing station equipped with a jaw crusher. It is widely used in mining, construction, infrastructure construction, environmental protection and other fields. It can effectively crush rocks and ores of various hardnesses and types. It consists of jaw crusher, feeder, vibrating screen, conveyor belt and control system. Through reasonable selection and use, mobile jaw crushing stations can help improve production efficiency, reduce costs, reduce dependence on natural resources, and achieve the goal of sustainable development.

The key components of a mobile jaw crushing plant include:

Jaw crusher: Jaw crusher is the core part of the crushing station. It consists of a fixed jaw plate and a movable jaw plate, which achieves crushing by compressing rocks or ores. Different models of jaw crushers are suitable for different types of rocks and ores.

Feeder: The feeder is used to transport rocks or ores into the jaw crusher to ensure continuous operation of the crusher. It can use a vibrating feeder or a belt feeder, choose according to your needs.

Vibrating Screening Machine: Vibrating screening machine is used to screen the crushed materials and separate out the required particle size. This is particularly important because different applications require different sizes of finished material.

Conveyor belt: Conveyor belt is used to transport the crushed finished materials from the crushing station to the required location, such as a stacking area or transportation equipment.

Control system: The control system is used to monitor and adjust the operation of the entire crushing station, including the start and stop of the jaw crusher and the control of material transportation. Modern mobile jaw crushing plants are usually equipped with advanced automated control systems to improve efficiency and safety.

Product Performance

- 1Easy to move and cost-saving

The mobile jaw crusher is equipped with a driving device and can be directly moved to the material site for work, greatly reducing the transportation of materials. cost.

- 2Integrated complete unit, saving space

The integrated unit equipment installation mode can eliminate the complicated site infrastructure installation work of separate components, and also It can reduce the consumption of materials and man-hours. Furthermore, this assembly method also occupies a relatively small area.

- 3Flexible configuration, more worry-free

This mobile jaw crusher can operate independently as a single unit, or it can be flexibly formed into a system to configure units for joint operation, or Combined into other systems according to on-site conditions, allowing customers to use them more worry-free.

- 4Green and environmentally friendly

The interior of the equipment has enhanced sealing performance, a self-circulating air system to reduce dust, and at the same time generates low noise, which meets the market's green and environmentally friendly requirements.

Working Principle

When the mobile jaw crusher is operating, the stones that meet the feed particle size are evenly transported to the jaw crusher through the feeder. After preliminary crushing by the jaw crusher, screening control is carried out. Only the qualified stones can be screened. Entering the next processing step, the closed-circuit system can realize cyclic crushing of materials. The finished materials are output by the conveyor for continuous crushing operations. The entire crushing process is smooth and highly productive, and the materials flow between various equipment at high speed.

Technical Parameters

| Model | Device configuration | Adjustable discharge opening (mm) | Output (t/h) | Outline dimensions (mm) |

| SL15L | ZSW3896+LF150 | 40-100 | 100-200 | 13050x2950x3100 |

| SL25L | ZSW4211+LF250 | 50-120 | 200-400 | 12750x3000x3700 |

| SL35L | ZSW4213+LF350 | 50-200 | 300-500 | 14360x3000x3800 |

| SE69L | ZSW3896+PE69 | 60-125 | 100-180 | 12500x2950x3000 |

| SC96L | ZSW3896+SC96 | 60-175 | 120-455 | 13500x3400x2800 |

| SC106L | ZSW4211+SC106 | 70-200 | 155-580 | 14400x3600x3000 |

| SC110L | ZSW1349+SC110 | 70-250 | 190-625 | 18470x6840x4700 |