Popular searched products:

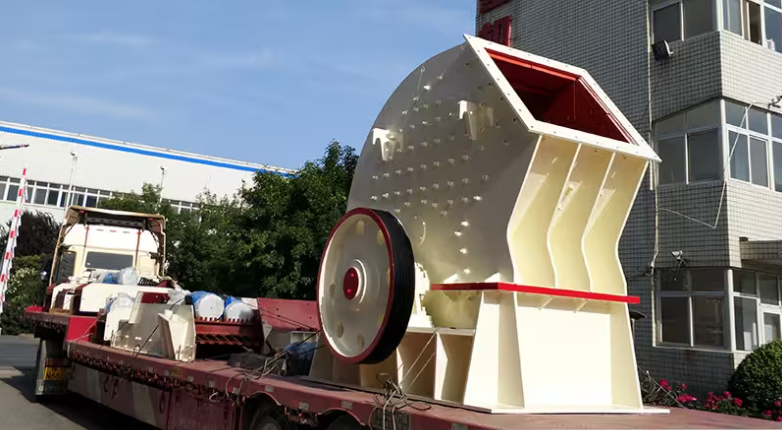

The hammer crusher can "set the shape with one hammer", which can reduce costs by about 40%. The hammer crushers produced by Henan Global Heavy Industry Crusher include PC hammer crusher, PCZ hammer crusher, and PCX hammer crusher. Among them, the PCZ hammer crusher has a larger feed (≤1200mm, production capacity 80-3000t/h); the PCX hammer crusher has a finer discharge (0-40mm discharge, production capacity 40-1200t/h), both It can be designed as a mobile model according to user needs.

Factors affecting hammer crusher production capacity

1. Material hardness

The harder the material, the harder it is to break and the greater the wear and tear on the equipment. The slower the crushing speed, the smaller the crushing capacity. This requires us to be moderate in the choice of materials.

2. Material humidity

That is, when the moisture content in the material is large, the material is easy to adhere in the crusher, and is also prone to blockage during the unloading and transportation process, resulting in a reduction in crushing capacity. To solve this problem, first of all, the temperature of the material must be strictly controlled when selecting the material. If the temperature of the selected material is too high, sun exposure or air drying can be used to reduce the moisture percentage in the material.

3. The material of the equipment itself

The better the wear resistance of the crushing parts (hammer head, jaw plate) of the crushing equipment, the greater the crushing capacity. If it is not wear-resistant, the crushing ability will be affected. In this regard, the broken parts of the crusher must be repaired regularly. If it is broken or damaged, it should be replaced in time to avoid affecting the normal operation of the crusher.

4. Worker proficiency

The proficiency of workers will indirectly affect the output of hammer crusher. Workers with more experience are less likely to make mistakes during operation and have more reasonable adjustments and controls for the equipment, allowing the equipment to achieve more reasonable output, while workers with less experience are not proficient enough with the equipment and often fail. If operational errors occur, output will also be affected.

How much does a hammer crusher cost?

How much does a hammer crusher cost? According to different manufacturers in different regions, the price positioning of hammer crushers will also be different. For example, regions such as Beijing, Shanghai, Guangzhou, and Zhejiang have relatively high consumption levels and relatively high manufacturing costs, while Henan is one of the cities with lower consumption levels in the country. It is a province with a large population, cheap labor, and low manufacturing equipment costs, so the price of equipment will be relatively cheap.

Related Reading

- Sand washing wastewater treatment technology helps you achieve zero discharge of sand washing wastewater

- These advantages make the sand washing machine the preferred equipment in the sand washing industry!

- I heard that the profit of machine-made sand washing is good, how much is it? Which equipment is suitable for machine-made sand washing?

- If you want to choose a cost-effective truck-mounted mobile sand washing machine, Zhengzhou Global Heavy Industry is your first choice

Product show

Product

Source:

Source: Time:2024/07/31 11:12:05

Time:2024/07/31 11:12:05