Popular searched products:

Product Description

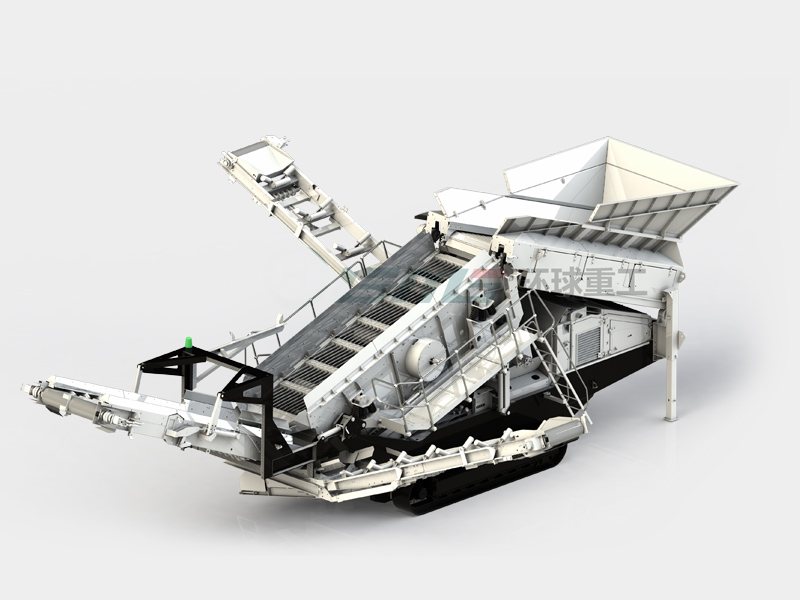

The structural design is compact, space-saving and reduces the floor space of the construction site.

The foundation treatment is simple and the equipment foundation is small, which avoids the complexity of civil construction.

All modules are pre-installed and assembled in the factory, which shortens the time of on-site installation.

The equipment process is coordinated and smooth, the selection and matching degree is high, and the operating efficiency is excellent.

The installation and maintenance process of the equipment is convenient and efficient, ensuring safety.

The removal and reinstallation of the modular station is very convenient, ensuring that the project can be quickly relocated and reassembled according to construction needs.

All standard modules can be loaded into standard containers for sea transportation.

Product Performance

1. The main function of the screening machine module station is to cooperate with the coarse crushing and medium and fine crushing modules to screen and grade the crushed products. 2. The structural design of the module station is simple and beautiful, and all independent components can be disassembled, which is convenient for assembly, disassembly and transportation. 3. The front of the screening machine module station is equipped with a slide-out discharge chute to facilitate equipment maintenance. 4. The module station is also designed with an assembleable lower discharge chute for easy transportation and installation. 5. The module station is equipped with ladders, handrails and wrap-around walkways to facilitate inspection and maintenance of various parts of the vibrating screen. The integrated modular crushing and screening station is a multifunctional integrated system solution that integrates one or more crushing and screening unit modules according to project requirements.Working Principle

Screening machine is a kind of equipment that can separate materials into different grades according to their particle size by allowing some particles to pass through the sieve holes through the relative movement between the bulk material and the sieve surface. The screening process is usually carried out continuously. After the raw materials are fed into the screening machine, the materials smaller than the sieve hole size will pass through the sieve hole, which is called the undersize product; while the materials larger than the sieve hole size will be continuously discharged from the sieve surface, which is called the oversize product.Technical Parameters

|

Model |

MS-2160 |

MS-2460 |

MS-2475 |

MS-2773 |

MS-3060 |

MS-3073 |

MS-3673 |

|

|

最大给料粒度(mm) |

200 |

200 |

200 |

200 |

200 |

200 |

200 |

|

|

Production Capacity(t/h) |

115-820 |

120-880 |

150-950 |

150-1100 |

150-900 |

150-1200 |

220-1500 |

|

|

Screen layers |

2/3/4 |

1/2/3 |

2/3 |

2/3 |

2/3 |

2/3 |

2/3 |

|

|

功率(kw) |

30/37/45 |

30/37/45 |

45/55 |

55 |

45/55 |

55/2*37 |

2*37/2*45 |

|

|

标准配置 |

振动筛 |

YKR2160 |

YKR2460 |

YKR2475 |

YKR2773 |

YKR3060 |

YKR3073 |

YKR3673 |

|

滑出式卸料槽 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

Fine material discharge chute |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

Platform Module |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

支座模块 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

Ladder handrail module |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|