Popular searched products:

Product Description

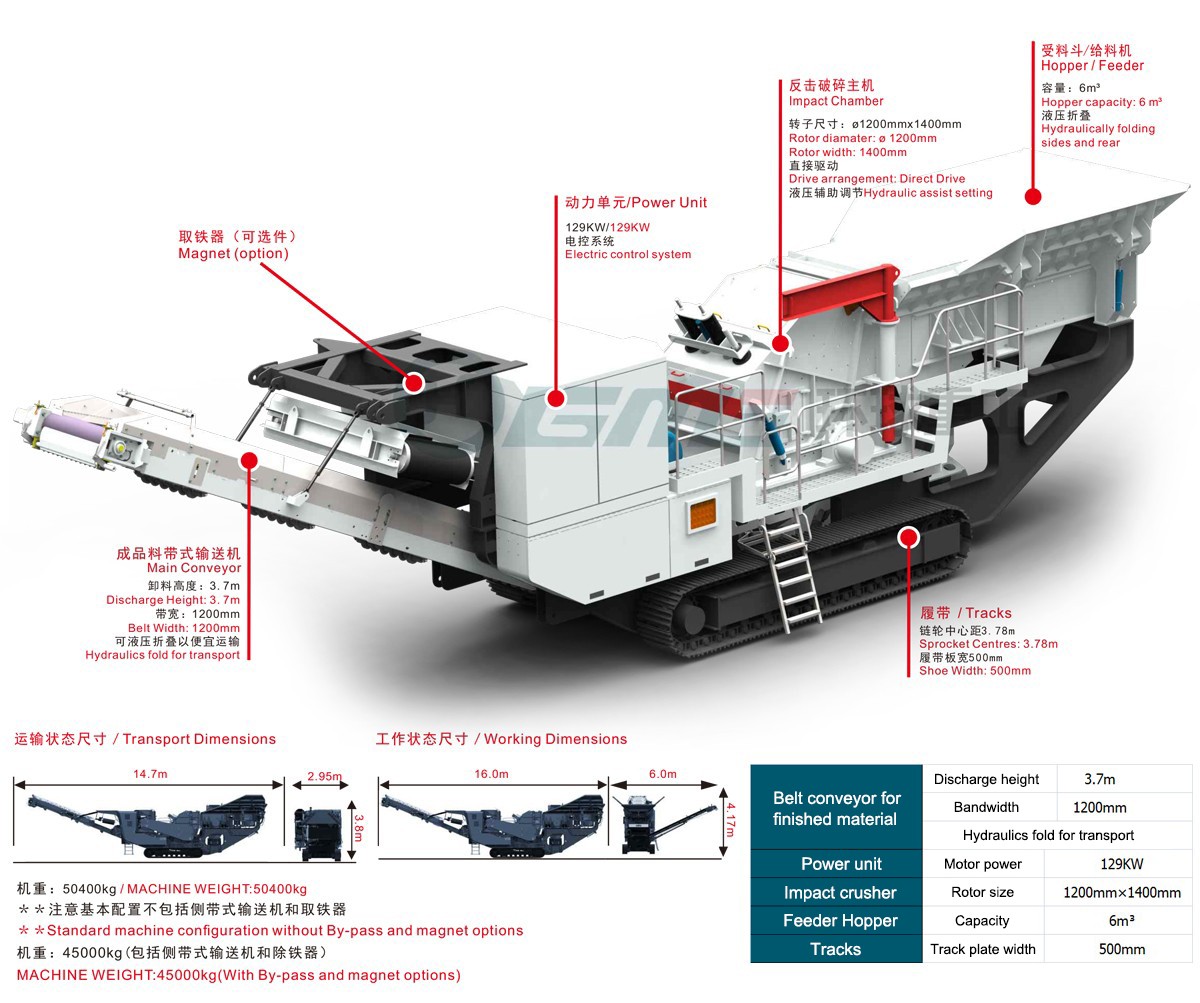

HI tracked impact crusher has been specifically designed for quarrying, mining, recycling and demolition applications. HI incorporates a HI impact chamber with direct drive and advanced electronic control system. The large hopper features a variable speed VGF feeder and is available with an optional independent pre-screen with constant RPM for optimum separation even if feeder speed is reduced. The machine provides operators high material reductions ratios and produces an excellent product shape.

Product Performance

Fully hydraulic assisted apron setting features makes adjustment of the aprons convenient and efficient.

Heavy duty vibrating feeder (VGF) with integral pre-screen removes dirt fines and sizes by pass material for reprocessing.

Optional under crusher vibratory plate feeder with wear resistant liners aids material discharge flow and reduces under crusher blockages.

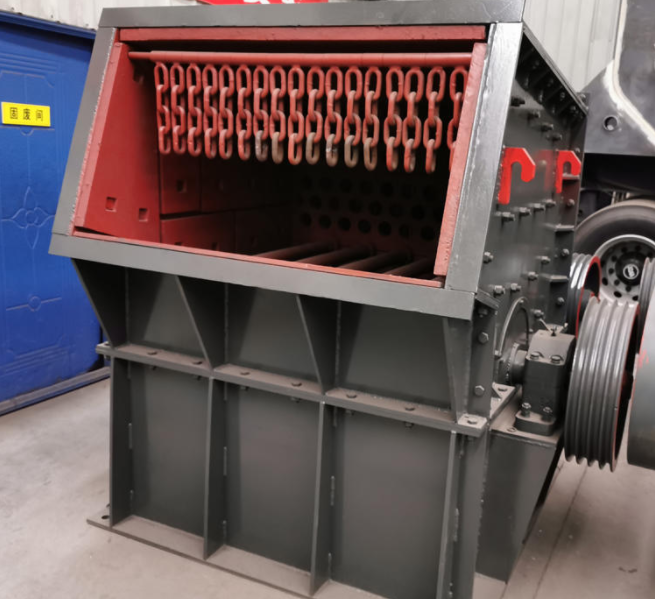

Efficient direct drive crusher chamber is supplied with a 4 bar rotor as standard.

Working Principle

Impact mobile crushing station is a kind of crushing machine which uses impact energy to break materials. When the machine is working, driven by the motor, the rotor rotates at a high speed. When the material enters the plate hammer action zone, it is crushed by the plate hammer on the rotor, and then it is thrown to the counter device to break again, and then springs back from the counter liner to the plate hammer action zone to break again. This process is repeated until the material is broken to the required particle size and discharged by the discharge port.

Technical Parameters

| HI721 | HI731 |

| Chamber | |

| 1412IMPACTCHAMBER | 1513IMPACTCHAMBER |

| 4 bar rotor | 4 bar rotor |

| Hydraulically assisted apron setting | Hydraulically assisted apron setting |

| Feeder Hopper | |

| Hopper capacity:6m³ | Hopper capacity:6m³ |

| Hydraulically folding hopper sides | Hydraulically folding hopper sides |

| Heavy duty vibrating feeder | Heavy duty vibrating feeder |

| Stepped grizzly feeder with integral pre-screen, standard 30-50mm spacing | Stepped grizzly feeder with integral pre-screen, standard 30-70mm spacing |

| Selectable discharge to by-pass conveyor or main conveyor | Selectable discharge to by-pass conveyor or main conveyor |

| Mesh aperture on grizzly feeder: 38mm | Mesh aperture on grizzly feeder: 38mm |

| Main Conveyor | |

| Belt width: 1200mm | Belt width: 1000mm |

| High spec scraper at head drum | High spec scraper at head drum |

| Optional vibratory feeder under crusher | Optional vibratory feeder under crusher |

| General | |

| Piped for dust supression complete with spraybars | Piped for dust supression complete with spraybars |

| Piped for overband magnet | Piped for overband magnet |

| Track is soft start with 2 optional speeds | Track is soft start with 2 optional speeds |

| Hand Held Track Control Set with Connection Lead | Hand Held Track Control Set with Connection Lead |

| Heavy duty undercarriage unit with 500mm shoe width | Heavy duty undercarriage unit with 500mm shoe width |

| Low level greasing points | Low level greasing points |

| Galvanised catwalk c/w handrail, kick board and access ladders | Galvanised catwalk c/w handrail, kick board and access ladders |

| Emergency stops(6 nr) | Emergency stops(6 nr) |