Popular searched products:

Product Description

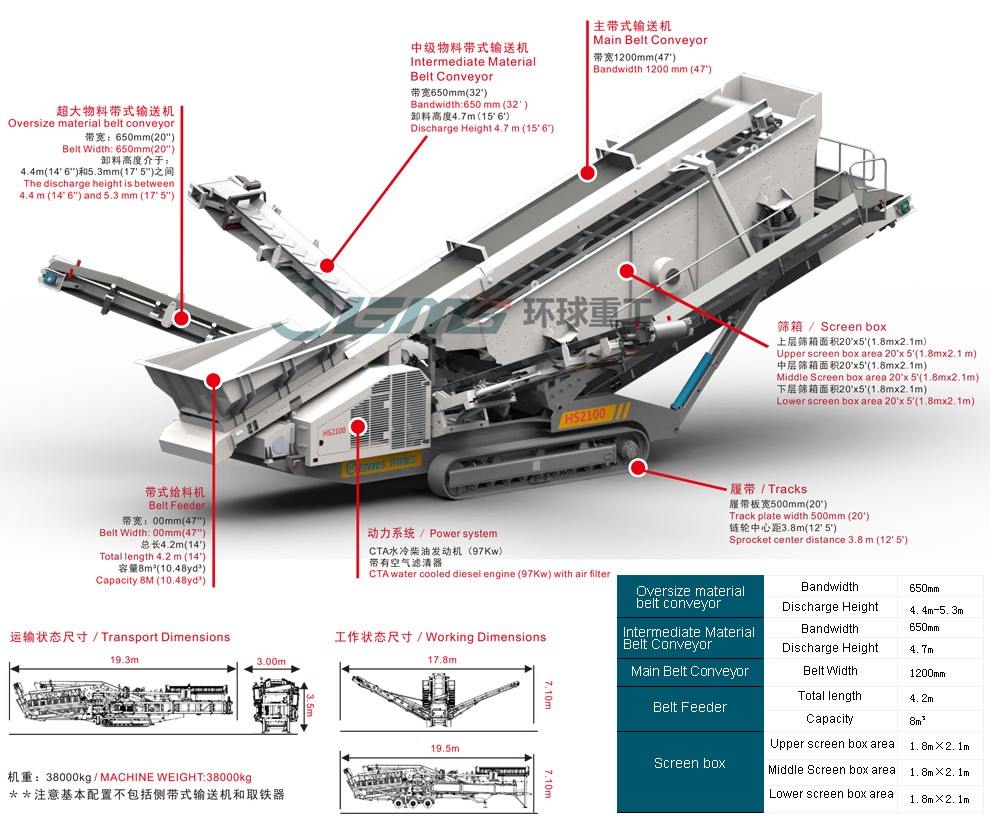

The new HS is the industry’s leading tracked mobile tilting screen equipment, with the best production level, the shortest installation time and the most convenient operation. Large- capacity belt feeders are equipped with either a remote-turning Mesh screen or a single/double vibrating Mesh screen. The new three-layer screening structure is equipped with a three- layer screen of 20'x 5'(6.1mX1.525m) . The innovative hydraulic control system enables the four-stage conveyor belt to make simple position adjustment during stacking and feeding

Product Performance

New three-layer screen box, screen size 20'x 5'(6.1mx1.525m) screen box around the installation of operating channels.

The combination of fast wedge tensioning device, convenient inspection holes and bottom hydraulic tensioning device minimizesscreeninstallation and replacement time.

The three large size screens 20'x 5'(6.1mX1.525m) guarantee super eficient screening capacity, even for fine aggregate.

Four-slage (extra large) belt conveyors can be tilted or rotated to adiust the discharge position to ensure the crusher accuralefeeding and stacking requirements.

Working Principle

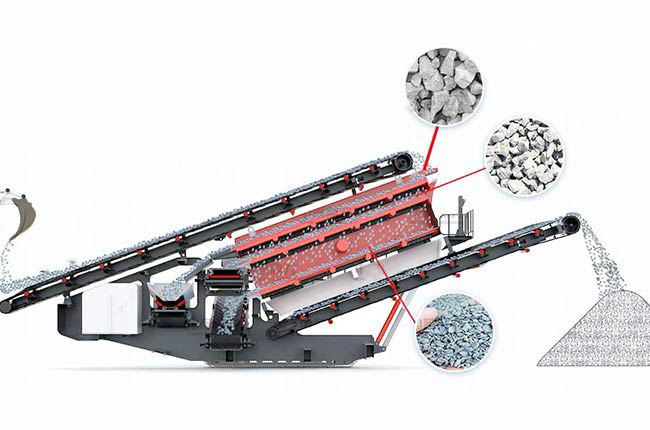

The mixed material is transported to the top of the vibrating screen by the sieve epithelium belt machine through the buffer bin. The eccentric block of the vibrating screen generates centrifugal force to stimulate the circular motion of the sieve box. After the material falls into the vibrating screen screen, the first layer screen screen will screen out large size materials, which will generally be returned to the crushing equipment for secondary processing by the conveyor belt. The finished material separated from the two-layer or three-layer screen is transferred to the finished material pile respectively by the belt measuring machine or the belt screening machine through the dividing hopper.

Technical Parameters

| HS2000 | HS3000 |

|---|---|

| Basic configuration | |

| The hopper is 4.25 m (14) long with a capacity of 8m³(10.5 yd³) | The hopper is 4.25 m (14) long with a capacity of 8m³(10.5 yd³) |

| The hydraulically driven Mesh screen can be turned over remotely to remove the blockage and a locating pin can be installed | The hydraulically driven Mesh screen can be turned over remotely to remove the blockage and a locating pin can be installed |

| Screen box | |

| The area of the three-layer screen is 6.1mx1.52m (20x5) | The area of the three-layer screen is 6.1mx1.52m (20x5) |

| Mesh Size: 4.25mm-100mm | Mesh Size: 4.25mm-100mm |

| The upper and middle layer screen adopts side tension, the lower layer screen adopts bottom tension and the lower layer screen adopts hydraulic tension | |

| The upper and middle layer screen adopts the wedge-shaped quick tensioning device | The upper and middle layer screen adopts the wedge-shaped quick tensioning device |

| Screen hole specification according to customer needs to order separately (the equipment basic configuration does not contain the screen, but reserves the structure which installs the scree n) | Screen hole specification according to customer needs to order separately (the equipment basic configuration does not contain the screen, but reserves the structure which installs the scree n) |

| An operating channel, handrails, pedals and steps are arranged around the screen box | An operating channel, handrails, pedals and steps are arranged around the screen box |

| Conveyer | |

| Main belt conveyor bandwidth 1200mm (48) | Main belt conveyor bandwidth 1400mm (48) |

| Fine aggregate belt conveyor bandwidth 1200mm | Fine aggregate belt conveyor bandwidth 1400mm |

| Huge material belt conveyor adopts 500mm belt with herringbone pattern | Huge material belt conveyor adopts 500mm belt with herringbone pattern |

| Large and medium material side belt conveyor adopts 650mm (32 '' ) bandwidth | Large and medium material side belt conveyor adopts 650mm (32 '' ) bandwidth |

| Herringbone belt | Herringbone belt |

| Main belt conveyor with baffle, low lubrication requirements | Main belt conveyor with baffle, low lubrication requirements |

| General | |

| Heavy duty chassis track plate width 500mm | Heavy duty chassis track plate width 500mm |

| The hand-held remote control device can operate the machine in the range of 5m | The hand-held remote control device can operate the machine in the range of 5m |

| Meet the standards for quarrying and mining | Meet the standards for quarrying and mining |

| Low Lubrication requirement | Low Lubrication requirement |

| Emergency stop at four | Emergency stop at four |