Popular searched products:

Product Description

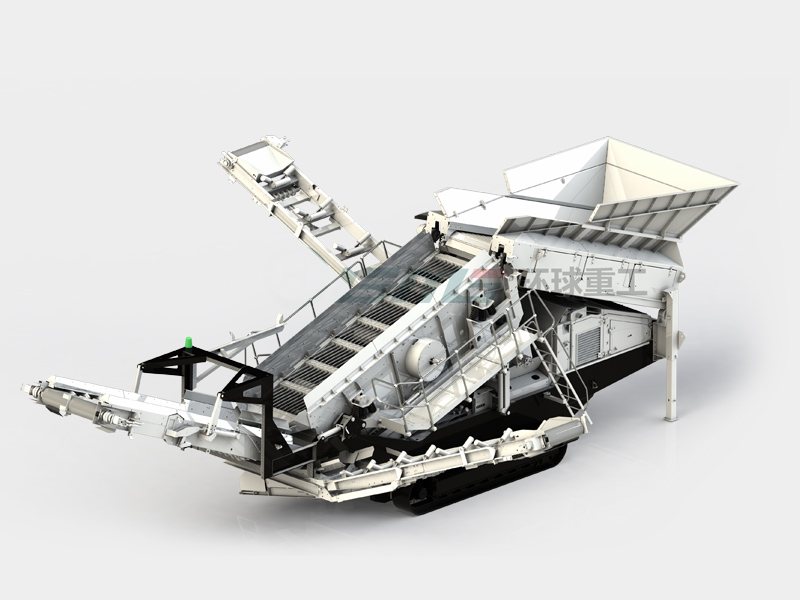

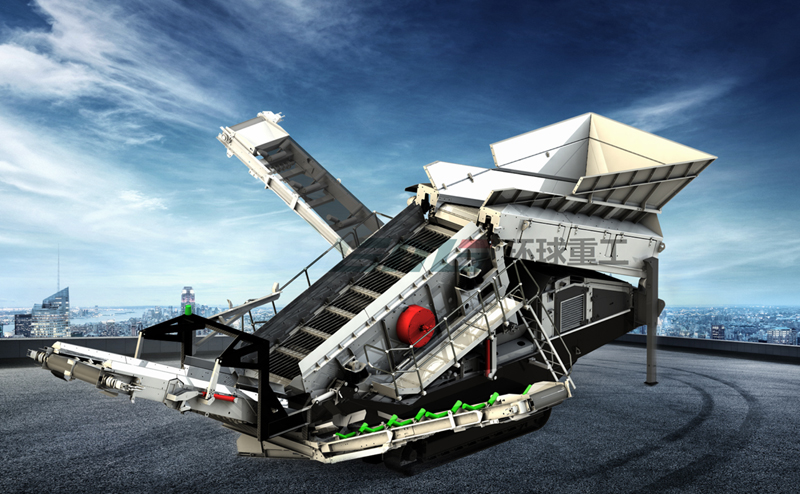

The excellent design of 883 makes it possible to operate incombination with the primary crusher and as a single highperformance crawler-mounted mobile screening station forfirst-line screening.883 can be used in quarries, mineconstruction, building demolition and crushing treatment,surface soil treatment, material recycling, gravel screening,coal and aggregate screening, processing capacity of up to 500tons per hour. 883 always works well in any application.

Product Performance

- 1

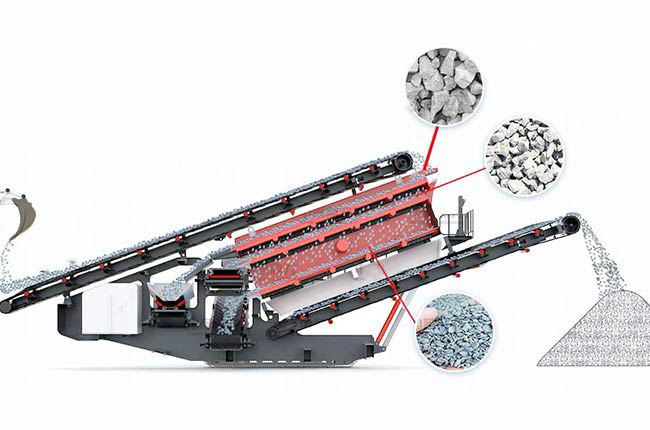

The high performance screen box can be fitted with a variety of screens, including BOFOR rod screen, slit screen.Mesh screen,perforated screen,finger screen.

- 2

The upper screen area of the combined structure is 4.8mx1.5m(16 x 5) , and the lower screen area is 3.65mx1.5m(12 x 5)

- 3

The tilting angle of the screen box can be adjusted from 13° to 19° by hydraulic device.

- 4

The discharge port of the screen box can be lifted up to 500mm by a hydraulic device in order to replace the screen Mesh.

- 5

All unloading belt conveyor angle can be adjusted by hydraulic device.

Working Principle

The mixed material is transported to the top of the vibrating screen by the sieve epithelium belt machine through the buffer bin. The eccentric block of the vibrating screen generates centrifugal force to stimulate the circular motion of the sieve box. After the material falls into the vibrating screen screen, the first layer screen screen will screen out large size materials, which will generally be returned to the crushing equipment for secondary processing by the conveyor belt. The finished material separated from the two-layer or three-layer screen is transferred to the finished material pile respectively by the belt measuring machine or the belt screening machine through the dividing hopper.

Technical Parameters

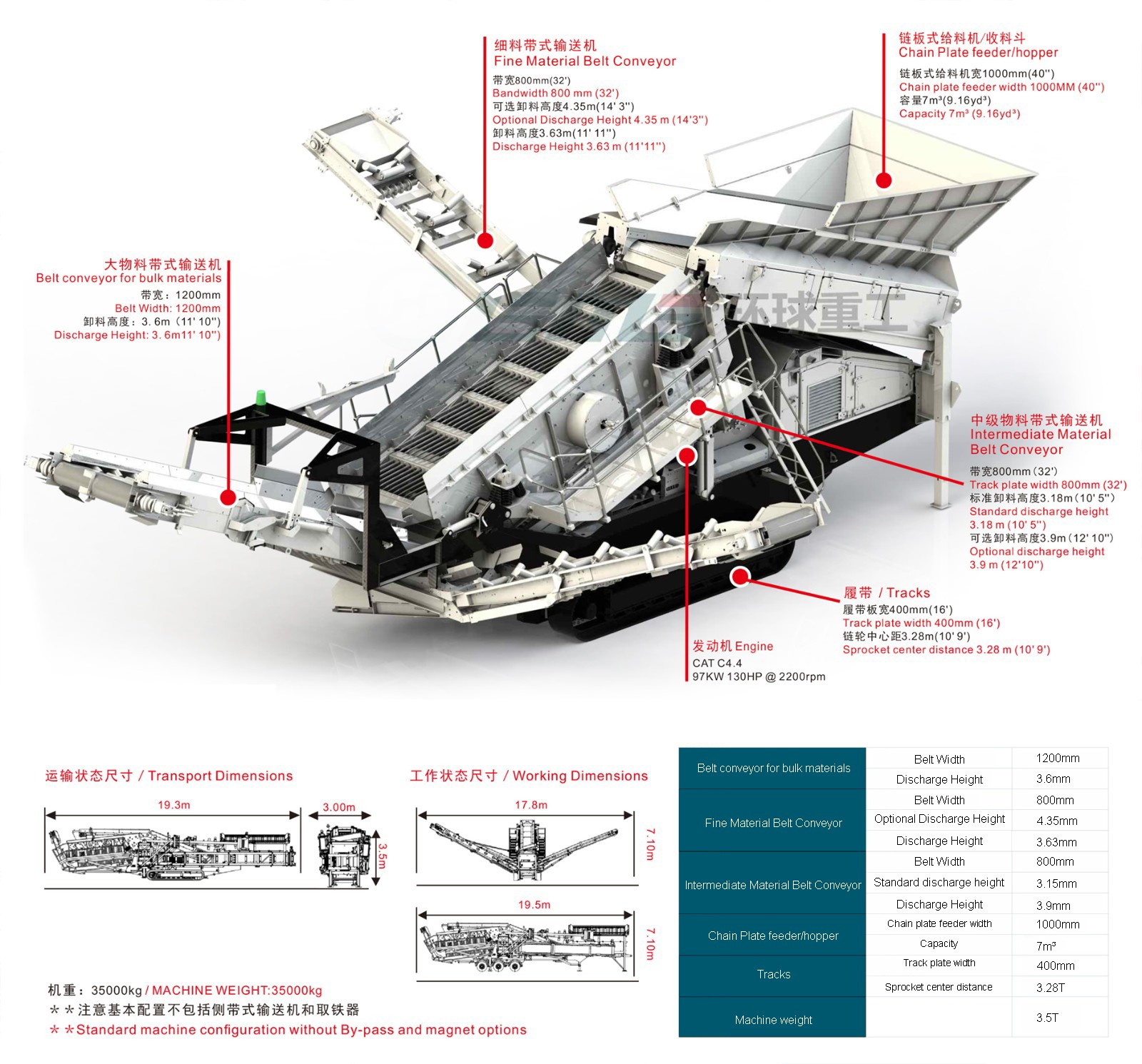

Basic configuration

Cat C4.4(130Hp/97Kw) additional air pre-filter

Chain Plate Feeder and apron are made of wear resistant steel plate and driven by heavy chain

The hopper capacity is 7m³(9.16 cu, yards)

Screen box

MESHLESS structure

Combination screen

A hydraulic device is used to lift 500mm to replace the screen Mesh

Screen hole specification according to customer needs to order separately (the equipment basic configuration does not contain the screen, but reserves the structure which installs the screen)

The size of upper screen is 4.8m × 1.5m (16'× 5')

The size of the lower screen is 3.65m × 1.5m (12'× 5')

The fuselage is surrounded by aisles with handrails, pedals and ladders

The screen box is provided with a garbage discharge groove

Conveyer

The belt conveyor for large materials adopts 1200mm (48”) belt with herringbone pattern and double-motor drive (discharge height is 3.6 m) with baffle plate

Intermediate material conveyor adopts 800mm (32”) belt with herringbone pattern and adjustable speed to drive the drum.

Fine-grade material conveyor adopts 800mm (32”) wide common conveyor belt and adjustable speed drive roller,equipped with conveyor belt scraper.

General

The chain plate feeder can be opened/stopped remotely

Heavy duty track chassis, track plate width 400mm, sprocket center distance 3280mm

The hand-held remote control device can operate the machine in the range of 5M

Meet the standards for quarrying and mining

Low Lubrication requirement

Emergency stop at four