Popular searched products:

Product Description

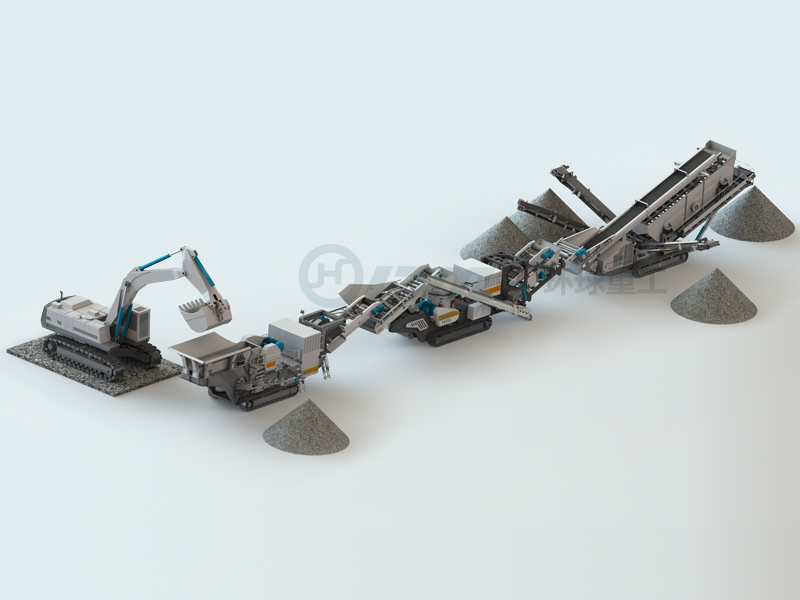

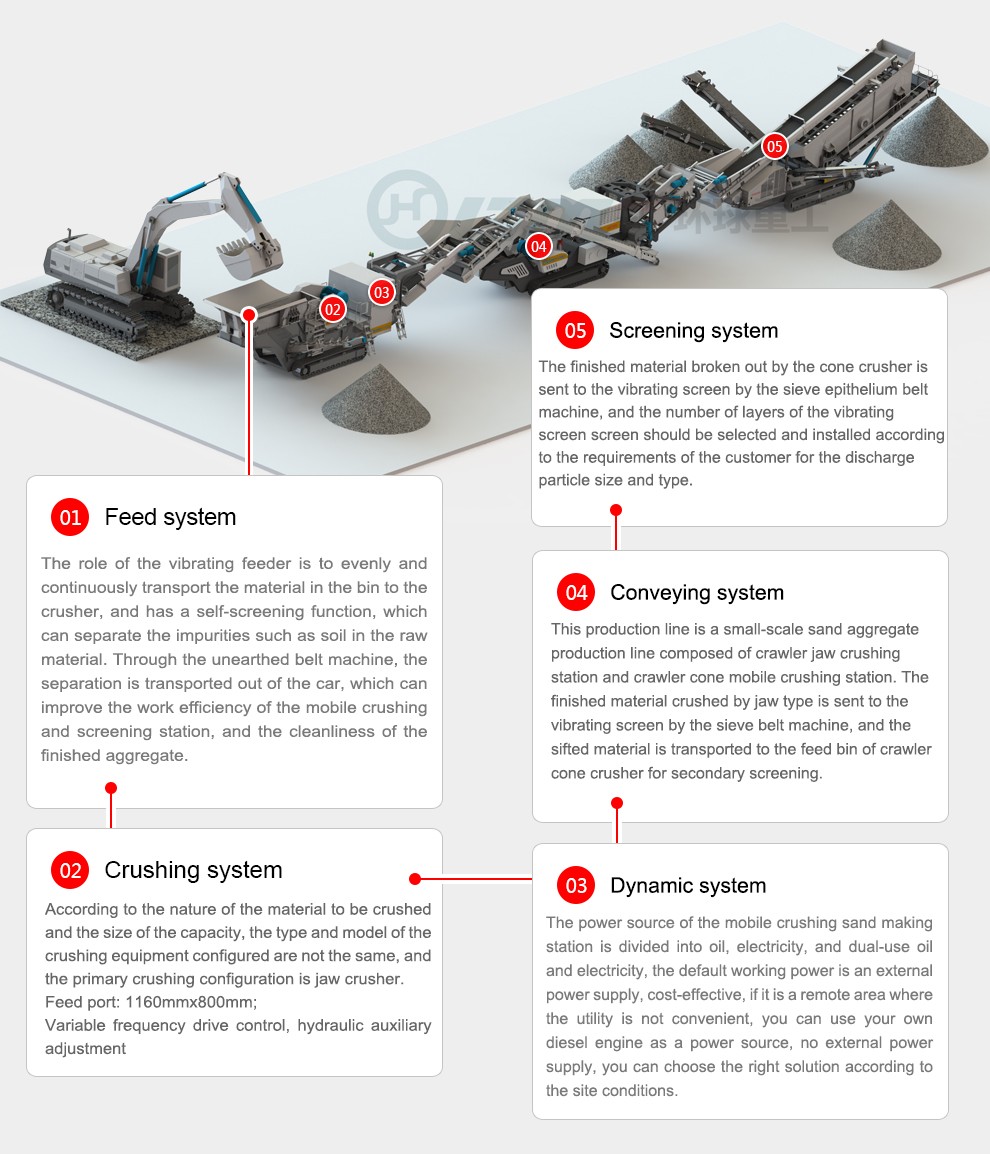

Jaw mobile crushing station, also known as coarse crushed tire mobile crushing station, is a mobile crushing equipment composed of three major systems of feeding, crushing and conveying, using an integrated operation mode, eliminating the installation of complex site infrastructure and auxiliary facilities, and replacing the traditional fixed coarse crushing production line in more application fields, which can be operated separately. It is also equipped with other mobile crushing machines to work together.

Cone type mobile crushing station is a kind of mobile crusher equipment for crushed tires, the overall modular design, equipped with cone breaking + vibrating screen + conveyor, suitable for two and three stages of crushing, divided into caterpillar type and tire type, the main machine crushing system can be freely matched with single cylinder, multi-cylinder, full hydraulic cone breaking, the fuselage is flexible, intelligent operation, green environmental protection, It reduces the tedious process and man-hour consumption of infrastructure installation, and can gain a firm foothold in the sand plant.

Product Performance

The track walking and equipment stretching and folding are driven by the engine. After the site is in place, the external power supply drives the feeder, crushing machine, belt conveyor and other work.

Compared with the equipment driven by the pure diesel engine, the equipment can greatly save the power cost for the user.

The equipment retains the convenience of mobile transfer of the tracked equipment and the superiority of rapid production on site.

When the equipment is working, the external power supply is driven, the engine is not started, the working time of the engine and the hydraulic system is less, and the maintenance cost is greatly reduced.

In the high altitude area, due to the electric drive during work, the high crushing efficiency can still be maintained.

Working Principle

Raw materials are fed into the silo by forklifts, excavators and other equipment, and the material in the silo enters the screening feeder, where the part of the raw materials with the required particle size leaks down from the screen hole and directly forms the mound through the unearthed belt conveyor; The larger material is broken through the sieve feeder into the jaw crusher, and then when the particle size reaches the standard, it is discharged from the discharge port into the vibration discharge machine; The discharging machine evenly sends the material to the main discharging belt machine, and the belt machine transports the material out to form a material pile; At the same time, an iron remover is installed above the main discharge belt, and the iron in the material is separated after being drawn by the iron remover.

The mixture (that is, the output of the crushing truck) enters the upper layer of the vibrating screen through the main feeding belt, forms different particle size aggregate levels after screening, and is transported to the material pile of different particle size through the finished belt to form the finished pile. The upper layer of the vibrating screen is the large particle size material that does not meet the requirements, and then returns to the crushing car for secondary crushing. If it is not used in conjunction with the crushing truck, it can be directly formed into a material pile.

Technical Parameters

| Feeding equipment | |

|---|---|

| Volumem³) | 6(Selectable 9) |

| Grate clearance(mm) | 40-70 |

| Feeder screen(mm) | 38 |

| Disc feeder(mm) | 4200×1100 |

| Crusher | |

| Type of crushing engine | Jaw crusher |

| Single knee(mm) | 1160×800 |

| Discharge port range(mm) | 70-225mm |

| Belt conveyor | |

| Width of main belt conveyor(mm) | 1200 |

| Discharge height(m) | 4.3 |

| Gear motor | 1×18.5KW |

| Side belt conveyor bandwidth | 650mm |

| Discharge height | 3.1m |

| Gear motor | 1×5.5KW |

| Whole machine | |

| Overall power(kw) | 129 Hydraulic drive |

| Capacity(t/h) | ≤500/tph |

| Machine weight(t) | 52 |

| Transport dimensions: length × width × height(m) | 20.6×7.4×5.1 |

| Feeder bandwidth(mm) | 1200 |

| Wear-resistant liner(mm) | 10-20 |

| Crusher | |

|---|---|

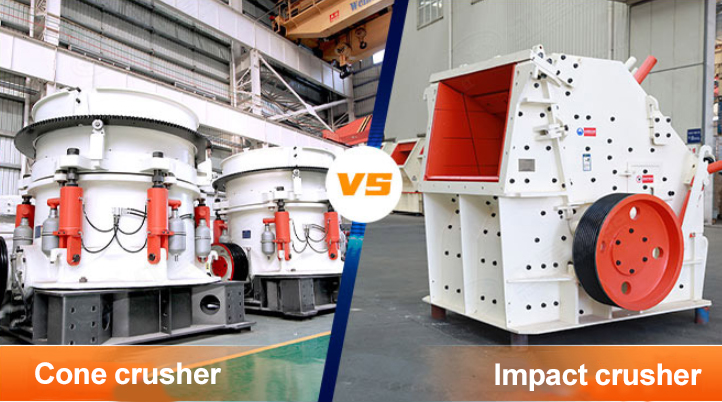

| Type of crushing engine | Cone crusher |

| Top diameter of moving cone | 1163-1366mm |

| Maximum feed size | 220mm |

| Belt conveyor | |

| Width of main belt conveyor | 1200mm |

| Discharge height | 3.8m |

| Transfer belt conveyor bandwidth | 1200mm |

| Return belt conveyor bandwidth | 500mm |

| Fine material belt conveyor bandwidth | 1400mm |

| Discharge height of fine material belt conveyor | 3.0m |

| Circulatory system | |

| Double screen size | 3.66m×1.52m |

| Screen size | 40mm |

| Whole machine | |

| Sprocket center distance | 3.8m-4.2m |

| Track plate width | 500mm |

| Overall power(kw) | 129 |

| Capacity(t/h) | ≤400/tph |

| Machine weight(t) | 55 |

| Transport dimensions: length × width × height(m) | 18.8×3.1×3.5 |