Popular searched products:

1. Which crushes stone better, cone crusher or impact crusher?

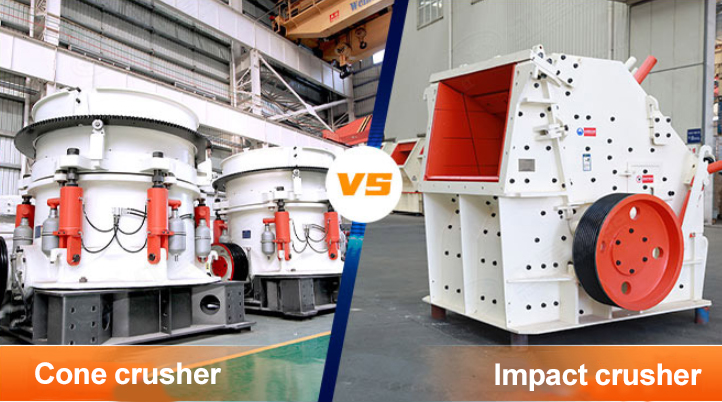

Which is better for breaking stones, cone crusher or impact crusher? It does not mean that the equipment has good performance and quality, but it crushes the stone better. The choice of crusher must consider many factors, such as the physical and chemical properties of the crushed raw materials, the production needs of the production line, and the user's financial budget.

In short, both impact crushers and cone crushers are often used as secondary stone crushing equipment. Both types of equipment have their own advantages, and their scope of application, crushing effect and purchase cost are different. In general, if you want to crush quartz stone, granite, and cobblestones, it is recommended to use a cone crusher to be more cost-effective. If the hardness of the stone is not high, but the production demand is large, you can choose a large impact crusher or multiple impact crushers to operate more cost-effectively.

2. Choose according to the hardness of the stone

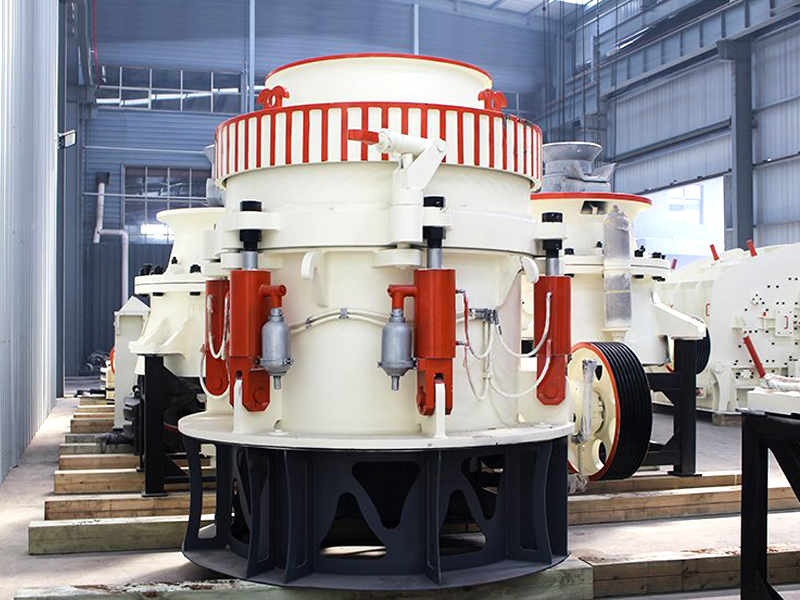

1. Hard materials and highly abrasive stones - cone crusher

The cone crusher adopts the laminated crushing principle and crushes materials through extrusion, which has a greater crushing capacity. Therefore, the cone crusher can easily crush stones with medium hardness, high hardness, and strong abrasiveness.

2. Medium hard, soft and low abrasive stone - impact crusher

The impact crusher adopts the impact crushing principle. The stone is repeatedly impacted between the plate hammer and the impact plate to reach the crushing particle size. It has high crushing efficiency and good crushing effect. It is suitable for medium-hard and low-abrasive stones with a compressive strength not exceeding 200MPa. Softer stones such as limestone and gypsum can also be crushed directly with impact crusher without first-level rough crushing, which greatly saves crushing costs.

3. Select according to production needs

1. With large output, low energy consumption and low discharging requirements, choose cone crusher.

The output of the cone crusher is between 18-725 tons per hour. The output is large and can meet the user's demand for high output. At the same time, it has low energy consumption, stable operation, low failure rate, long replacement cycle of wearing parts, and low later operating costs. The particle size of the material is small, suitable for stone crushing production lines with high output requirements.

2. High efficiency, low investment, high requirements on grain shape, choose counterattack.

Impact crushing has high operating efficiency and low purchase cost. The plate hammer and hammer head are easy-to-wear parts and need to be inspected and replaced regularly. The impact crushing principle makes the product grain shape better. The finished product is cube-shaped without tension and cracks. It is suitable for crushing product grains. Stone crushing production line with high requirements.

Related Reading

- Regarding product consultation on fine sand recovery machines, these are the most common questions!

- How to distinguish fine sand, medium sand and coarse sand? There are two ways to distinguish them.

- The wheel bucket sand washing machine has good sand washing effect and less fine sand loss. Sand makers are smiling!

- What factors affect the rise and fall of sand and gravel prices?

Source:

Source: Time:2024/05/15 10:04:13

Time:2024/05/15 10:04:13