Popular searched products:

1. Advantages and disadvantages of single-cylinder hydraulic cone crusher

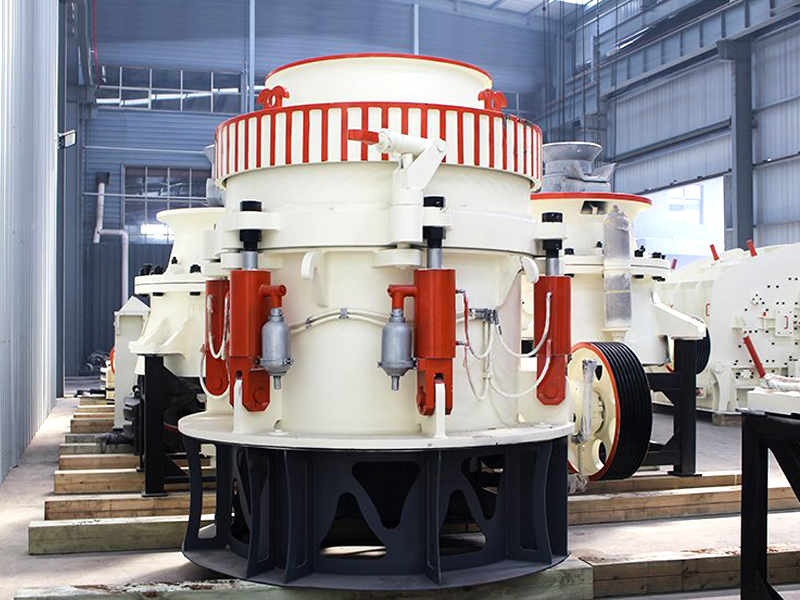

Advantages: 1. The single-cylinder hydraulic cone crusher has a simpler body structure and fewer parts than the multi-cylinder hydraulic cone crusher. In terms of appearance, the design is more refined.

2. Due to its simple structure and low manufacturing cost, the price is also lower than that of multi-cylinder hydraulic cone crushers.

3. During actual operation, the equipment is easy to install and maintain. And from a technical point of view, the single-cylinder hydraulic cone crusher has made technical improvements to the sliding bearings. The improved equipment can adapt to higher speeds and increase the swing speed of the spindle, making the finished material specifications more in line with requirements and increasing output. higher.

Disadvantages: The biggest disadvantage of single-cylinder hydraulic cone crushers is that there is only one cylinder, so the crushing force is smaller than that of multi-cylinder crushers. If you want to break some harder stones, it is recommended to choose a multi-cylinder crusher.

2. Advantages and disadvantages of multi-cylinder hydraulic cone crusher

Advantages: 1. The multi-cylinder hydraulic cone crusher has partially upgraded and improved the performance of the traditional spring-type cone crusher and has a reasonable structure. The equipment uses multi-cylinder hydraulic technology to give the crusher greater crushing capacity. While ensuring that the output reaches the target, energy consumption is also controlled. It is suitable for a wide range of stone materials, especially suitable for crushing stones with a hardness not exceeding 300Mpa.

2. The multi-cylinder hydraulic has a special crushing cavity design, which greatly improves the production capacity. The semi-automatic hydraulic adjustment of the discharge port can effectively control the particle size of the stone so that the finished material reaches the required specifications. Therefore, it is more economical and practical to use.

3. When manufacturing multi-cylinder hydraulic cone crushers, good crusher manufacturers will use high-strength overall cast shells and have iron protection, which is safe and reliable. No matter how hard the stone crushed by the equipment is, the performance of the equipment is very stable and long-lasting.

Disadvantages: The multi-cylinder hydraulic cone crusher adopts a labyrinth seal structure to prevent dust. But if it is a manufacturer with little experience or poor manufacturing technology, the labyrinth seal will also allow dust to enter. If the crushed stone contains a lot of dust, the adjustment of the discharge opening may become difficult. So be sure to choose a manufacturer with a good brand reputation.

Related Reading

- These advantages make the sand washing machine the preferred equipment in the sand washing industry!

- I heard that the profit of machine-made sand washing is good, how much is it? Which equipment is suitable for machine-made sand washing?

- If you want to choose a cost-effective truck-mounted mobile sand washing machine, Zhengzhou Global Heavy Industry is your first choice

- If you want to make sand washing production and processing more flexible, mobile sand washing station is your first choice!

Source:

Source: Time:2024/04/24 14:54:46

Time:2024/04/24 14:54:46